Speed-self-regulating synchronous generating system

A technology of power generation system and self-speed regulation, applied in the direction of control system, control generator, electrical components, etc., can solve the problems of increased failure rate, large occupied space and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

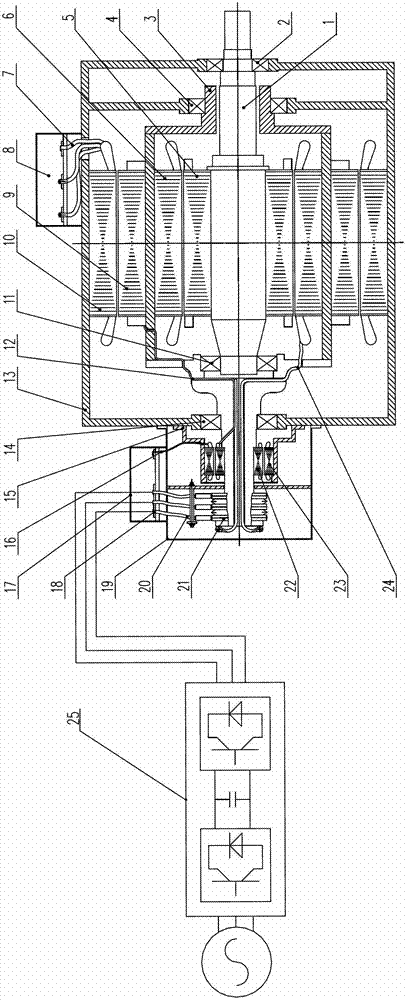

[0020] The system of the present invention integrates the frequency conversion speed regulation electromagnetic torque coupler and the electric excitation synchronous generator design, including the casing 13, the left side of the casing 13 is coaxially connected with the exciter, and the casing 13 is equipped with an electromagnetic torque coupling (not shown) and a synchronous generator (not shown) set on the outside of the electromagnetic torque coupling, the casing 13 includes a left end cover, a right inner end cover and a right outer end cover, and the right outer end cover The first bearing 2 of the inner rotor is arranged on the top, the first bearing of the outer rotor is arranged on the right inner end cover, the second bearing 14 of the outer rotor is arranged on the left end cover, and the electromagnetic torque coupling includes the inner rotor shaft 1 and the outer rotor shaft 3, An inner rotor 5 is fixed on the inner rotor shaft 1. The inner rotor shaft 1 protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com