Piezoelectric stack positioner with piezoelectric plates in different positioning directions stacked in turn

A piezoelectric sheet, stack positioning technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., and can solve problems such as asymmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

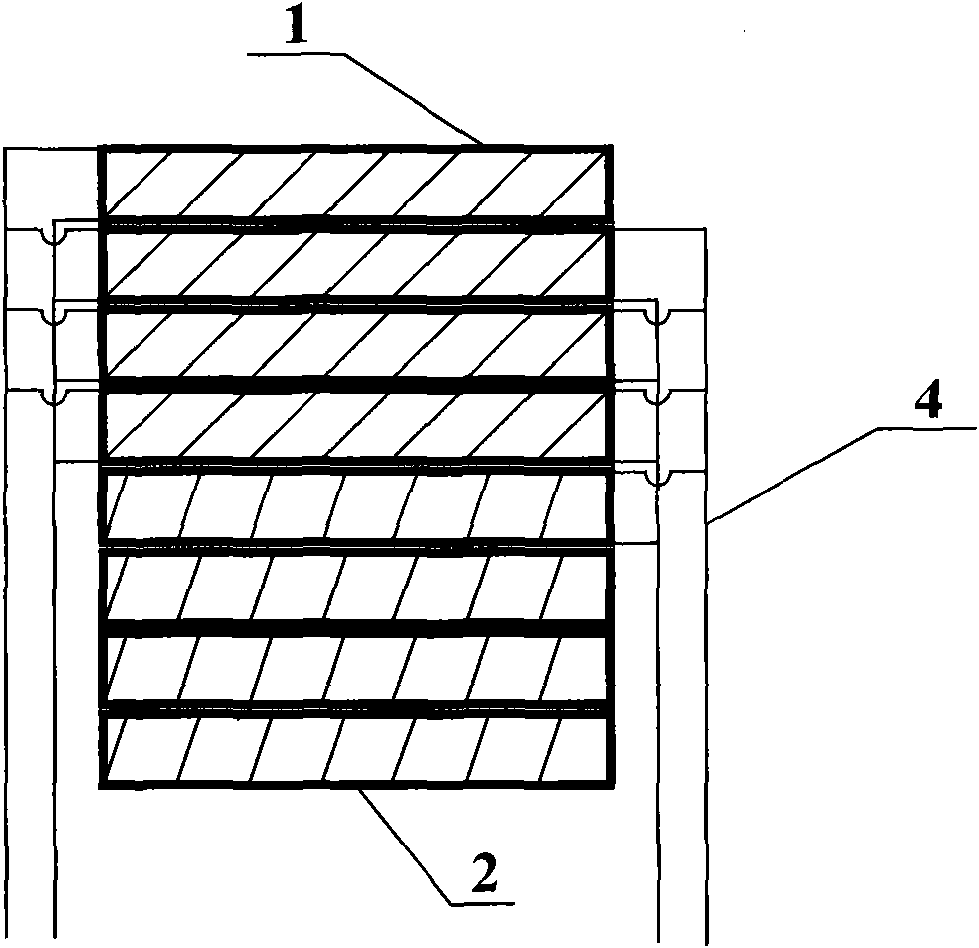

[0021] Embodiment 1: Piezoelectric stack positioner with two piezoelectric sheets positioned in different directions stacked in turn

[0022] See attached figure 2 In this embodiment, the piezoelectric stack positioner in which two piezoelectric sheets positioned in different directions are stacked in turn includes an X positioning piezoelectric sheet 1 and a Y positioning piezoelectric sheet 2, and is characterized in that the X positioning piezoelectric sheet 1 and the Y positioning piezoelectric sheet Y positioning piezoelectric sheets 2 are alternately stacked and fixed into a stack structure, where the connection between X positioning piezoelectric sheets 1 is mechanical series and electrical parallel connection 4, and the connection between Y positioning piezoelectric sheets 2 is also mechanical series connection and electrical parallel connection 1.

[0023] The working principle of this embodiment is: since the X positioning piezoelectric sheet 1 and the Y positionin...

Embodiment 2

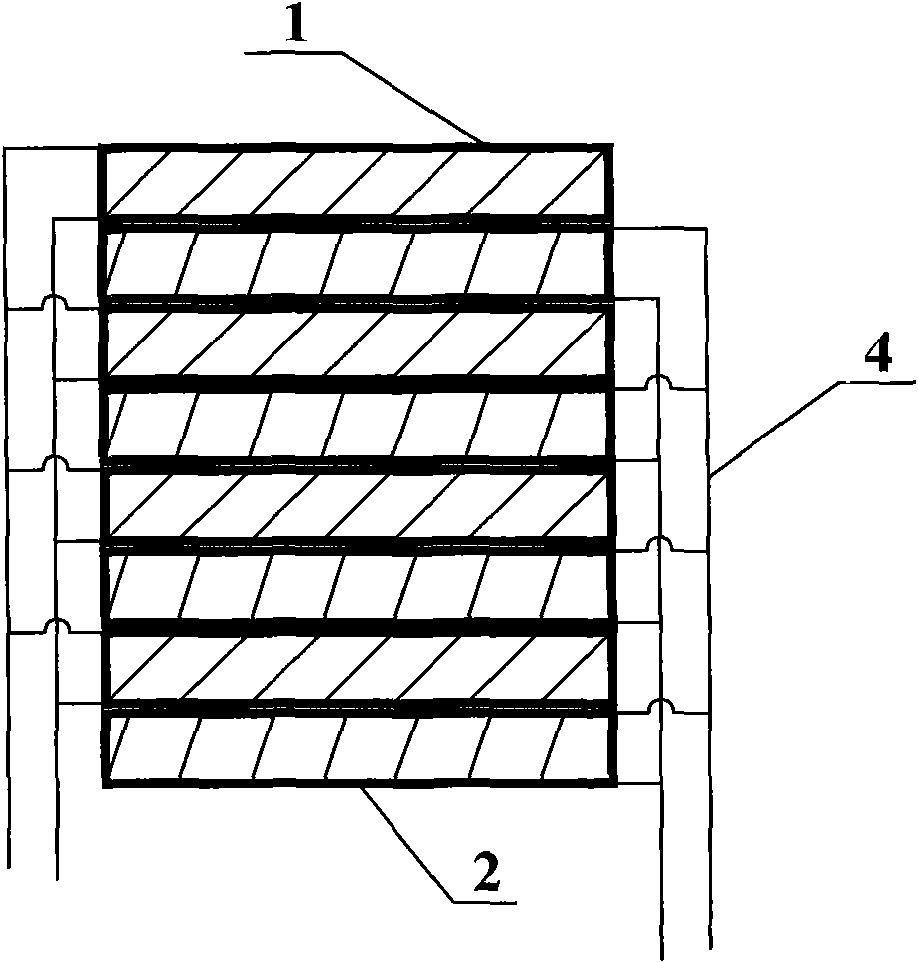

[0024] Example 2: Piezoelectric stack positioner made of tangential piezoelectric sheets with piezoelectric sheets positioned in two different directions stacked in turn

[0025] The X-positioning piezoelectric sheet 1 and the Y-positioning piezoelectric sheet 2 in the above-mentioned embodiment 1 may be tangential piezoelectric sheets (shear piezo plates).

Embodiment 3

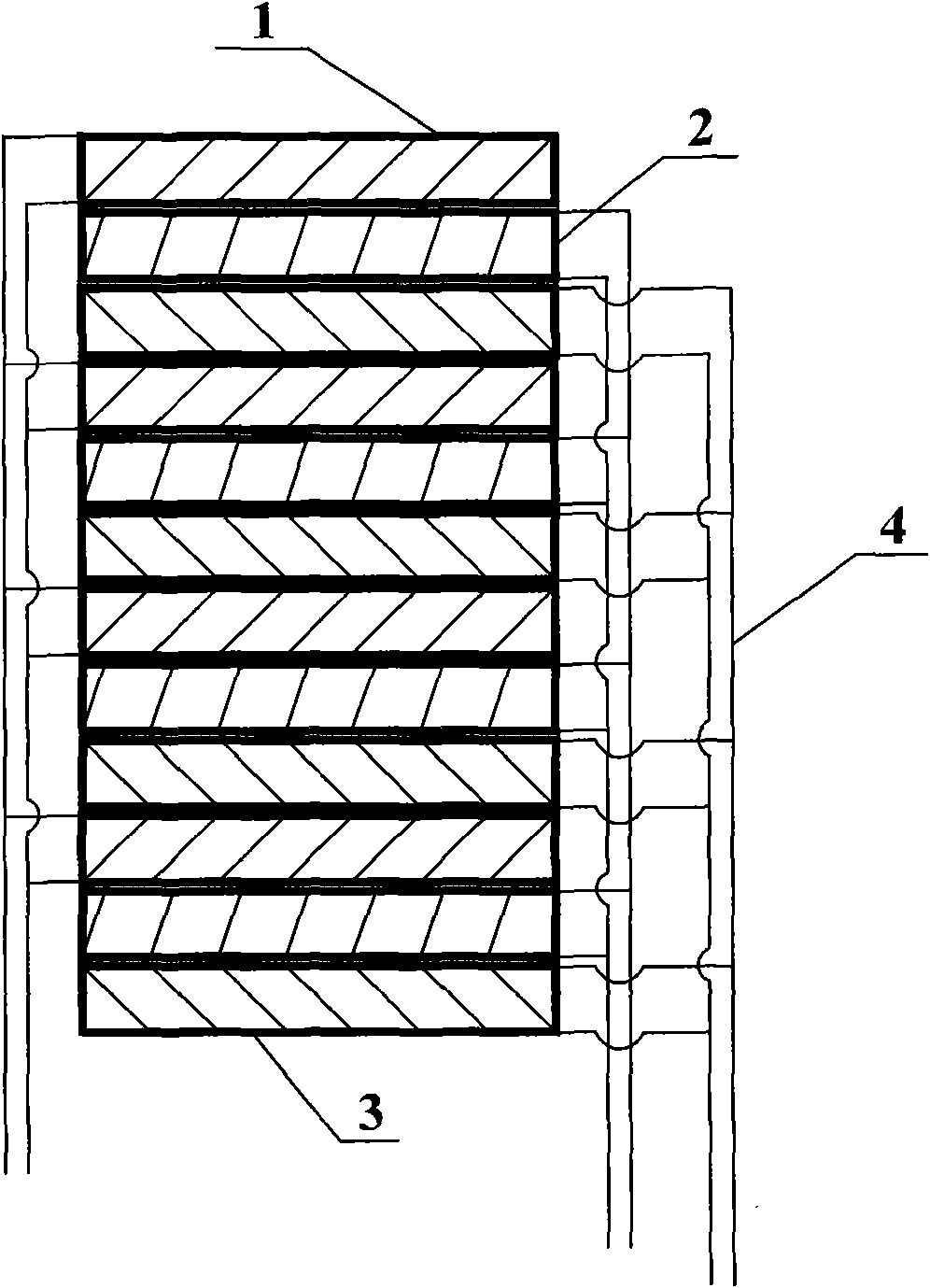

[0026] Embodiment 3: Piezoelectric stack positioner with three piezoelectric sheets positioned in different directions stacked in turn

[0027] See attached image 3 In this embodiment, the piezoelectric stack locator in which the piezoelectric sheets positioned in three different directions are stacked in turns includes an X positioning piezoelectric sheet 1, a Y positioning piezoelectric sheet 2, and a Z positioning piezoelectric sheet 3, which is characterized in that X positioning piezoelectric sheet 1, Y positioning piezoelectric sheet 2, and Z positioning piezoelectric sheet 3 are stacked and fixed in turn to form a stack structure, wherein the connection between X positioning piezoelectric sheets 1 is mechanical series and electrical parallel connection 4, Y The connection between the positioning piezoelectric sheets 2 is also a mechanical series connection and an electrical parallel connection 4 , and the connection between the Z positioning piezoelectric sheets 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com