Seedling grafting machine and grafting method of seedling grafting machine

A technique for grafting machines and seedlings, applied in botany equipment and methods, horticulture, applications, etc., can solve the problems of easy infection of bacteria in grafting incisions, slow fusion of cells on the cutting surface, and low survival rate of grafting, so as to save work space and avoid Effects of wound infection and work time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 grafting machine

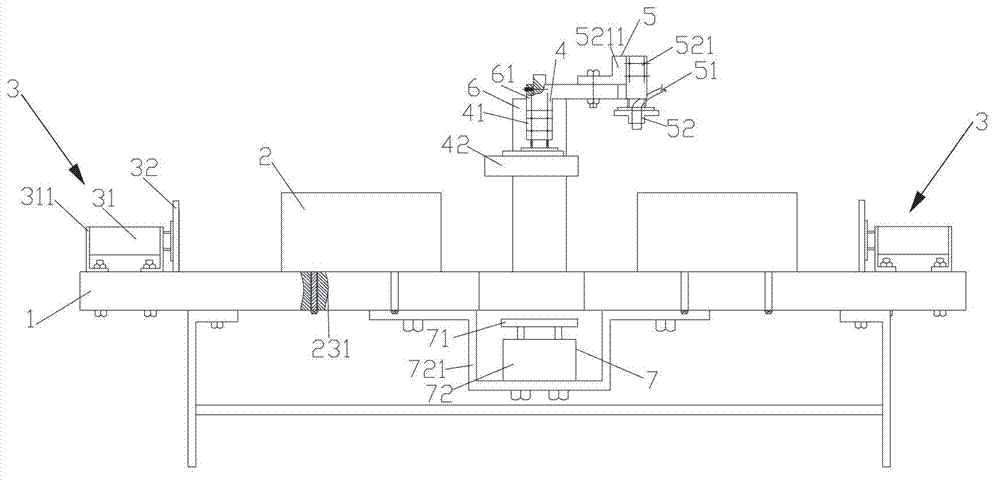

[0042] Design and manufacture grafting machine according to the present invention, structure such asfigure 1 Shown:

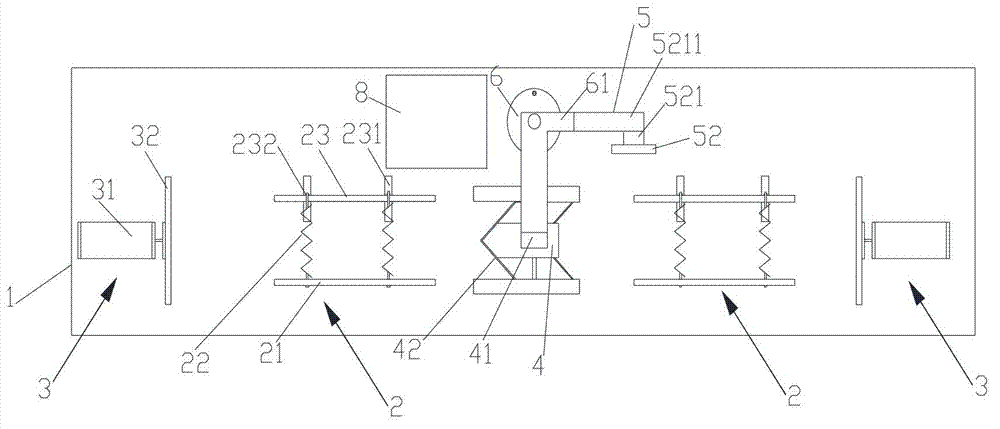

[0043] It consists of a workbench 1, a cutting joint device and two sets of seedling positioning devices, the cutting joint device is fixed in the middle of the workbench 1, and the two sets of seedling positioning devices are relatively fixed on the workbench 1 on both sides of the cutting joint device.

[0044] (1) Workbench 1: A workbench made of nylon board and angle iron.

[0045] (2) Seedling positioning device: it is composed of a seedling fixing part 2 and a seedling pushing part 3 .

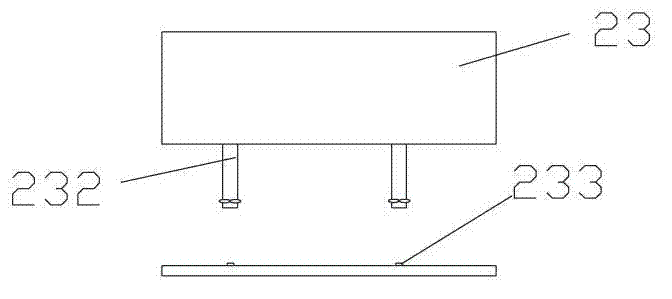

[0046] Seedling fixed part 2 is made up of fixed plate 21, spring 22 and movable plate 23.

[0047] The fixed plate 21 is fixed on the workbench 1 .

[0048] The structure of movable plate 23 is as image 3 As shown: two slide grooves 231 are provided on the workbench 1 at a certain distance inside the fixed plate 21, and two sli...

Embodiment 2

[0056] Embodiment 2 uses the grafting method of grafting machine

[0057] On April 12th, 2012, use the seedling grafting machine among the embodiment 1 to carry out grape seedling grafting, concrete steps are as follows:

[0058] 1) Locate rootstock and scion:

[0059] a) Fix the slightly end of the rootstock to the cutting joint device, and fix it in the seedling fixing part 2 facing the protruding side of the V-shaped cutter 42. The specific fixing method is to place one side of the rootstock close to the inside of the fixing plate 21 , the spring 22 and the movable plate 23 straddle the stock top, the movable plate 23 is inserted in the two chute 231 of the workbench 1 through two sliding pins 232, and the spring tension is guaranteed to fix the stock;

[0060] B) the root end of the scion is fixed in another seedling fixing part 2 toward the cutting joint device, and the specific fixing method is with reference to step a), and now the rootstock and the scion are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com