Power lead testing system and electronic tag

A detection system, power line technology, applied in the direction of circuit, connection, measurement of electricity, etc., can solve the problems of unresolved manual detection, manual detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

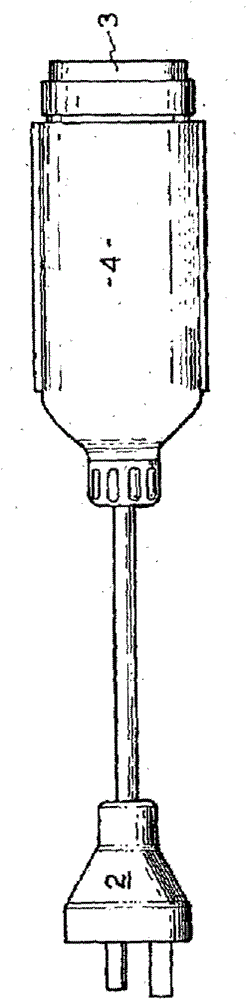

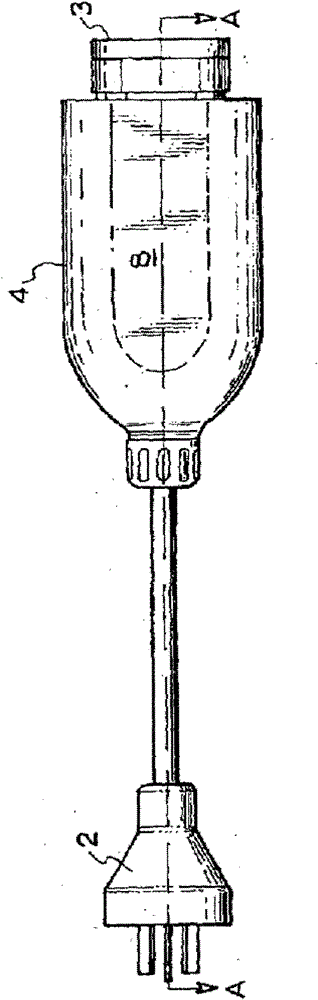

[0042] Figure 2 to Figure 5 A power cord 1 with a three-prong plug 2 and a socket 3 fitted with electrical connectors 4 is shown. Electronic header 4 contains Figure 7 The circuit shown in contains a power supply to convert mains power to 24 volt and 5 volt supplies, a microcontroller with battery backup for real-time countdown and communication with the detection device, a An infrared transceiver circuit and a relay for disconnecting mains power when a specified time has elapsed.

[0043] Sectional view Figure 4 A circuit board 6 is exposed which carries the circuitry described above and also contains LEDs 7 which indicate the condition of the wires 1 . A green LED indicates a safe wire, a flashing LED indicates that the wire will be disconnected within a specified period of time and requires retesting, and a red LED indicates that the wire cannot be used until retested. The transparent top 8 on the connector 4 enables the indicator LED 7 to be seen and also enables th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com