Metamaterial antenna

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

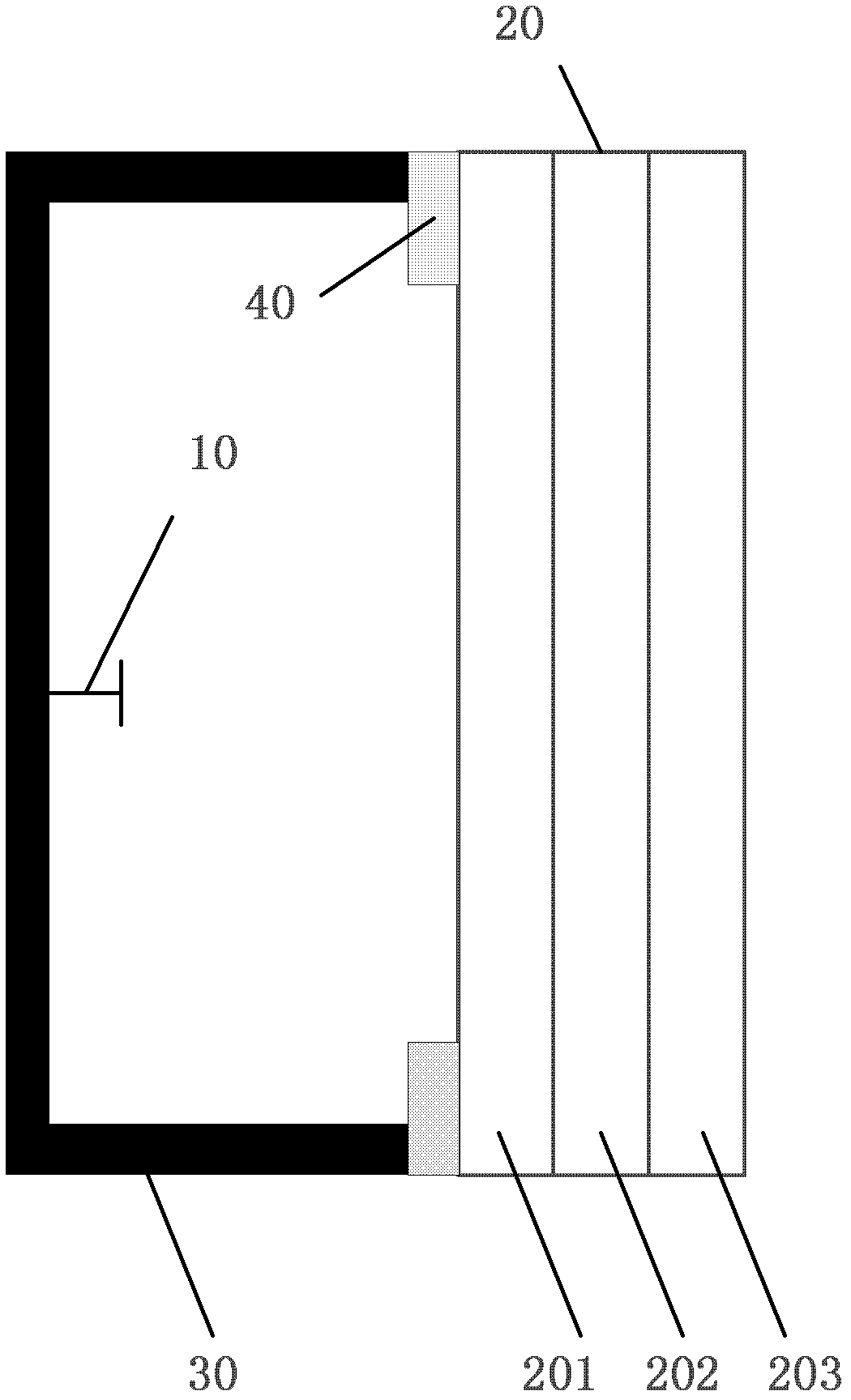

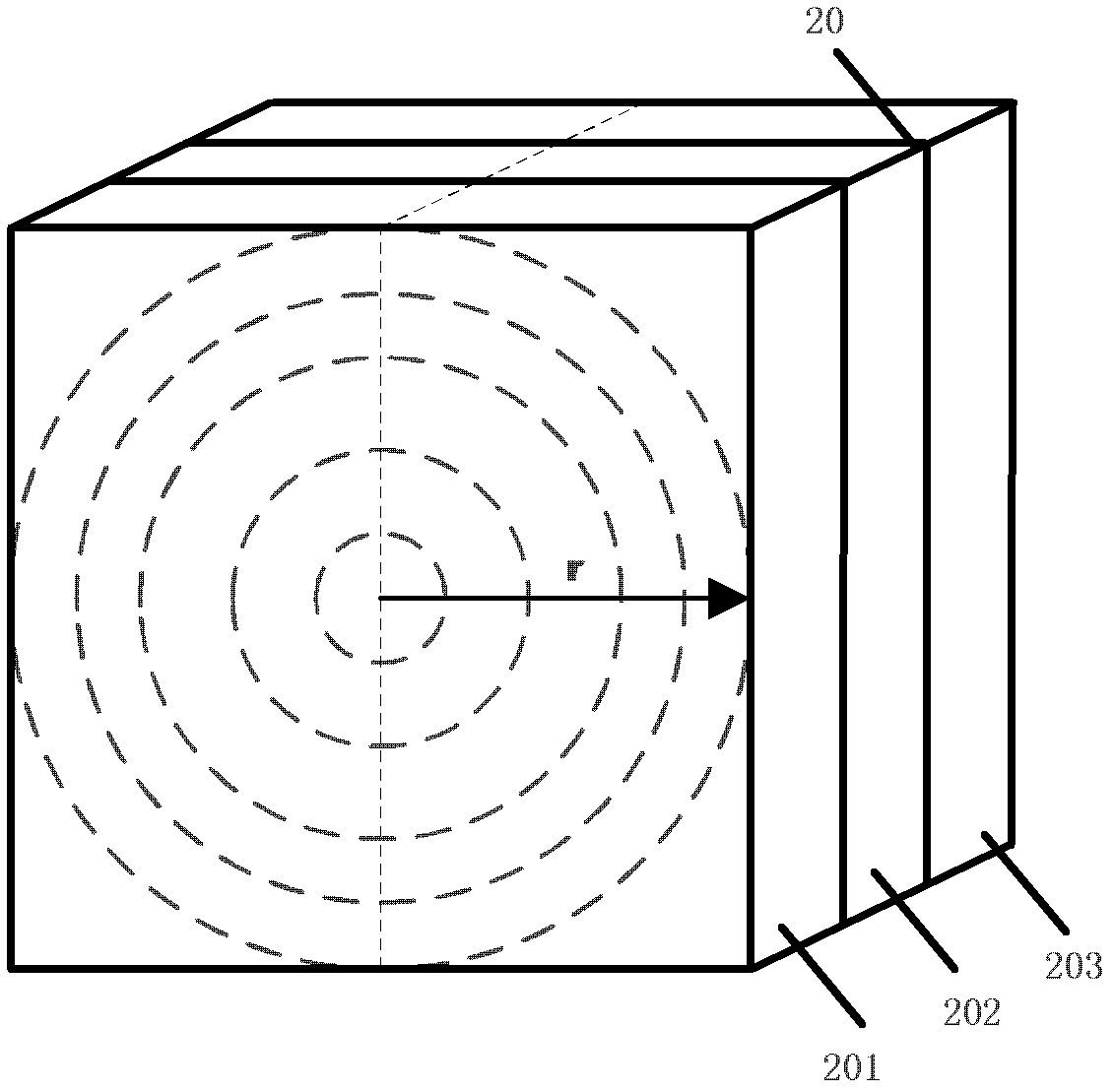

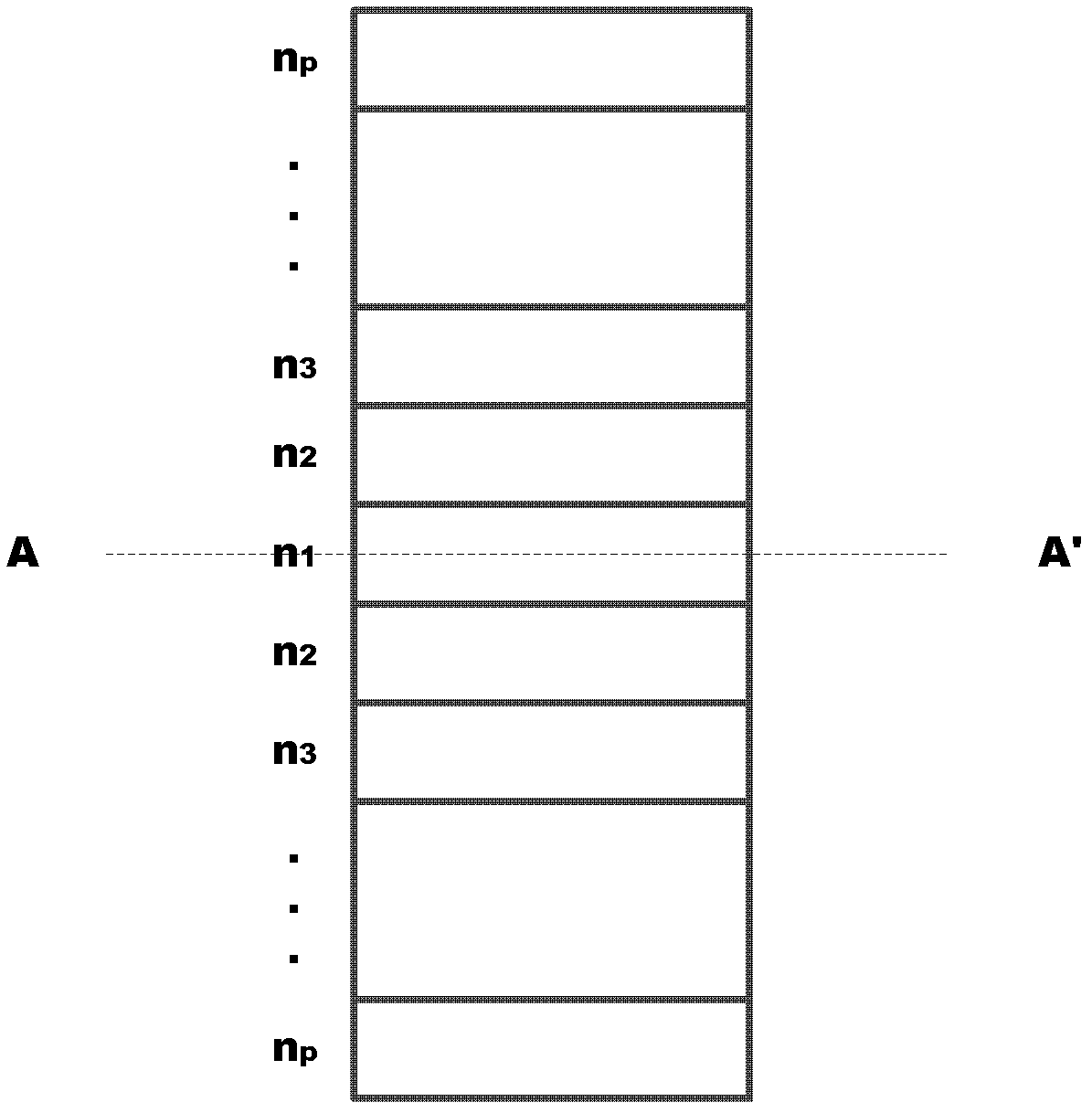

[0030] Metamaterial is a new type of material with artificial microstructures as the basic unit, which is spatially arranged in a specific way and has special electromagnetic response, including periodically arranged artificial microstructures and substrates for artificial microstructures to attach to. The artificial microstructure is a planar structure or a three-dimensional structure that is composed of at least one metal wire and responds to electromagnetic waves. Multiple artificial microstructures are arranged in arrays on the substrate. The portion of each artificial microstructure and the substrate it is attached to is A metamaterial unit. The substrate can be any material different from the artificial microstructure. The superposition of these two materials produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com