Vitrified silicon rubber insulation fireproof cable

A technology of ceramic silicone rubber, insulation and fire protection, which is applied in the direction of power cables, power cables with shielding layers/conductive layers, cables, etc., which can solve the problems of difficult installation, difficult mass production of mineral insulated cables, and poor economic benefits, etc. problems, to achieve the effect of convenient installation and laying, good anti-corrosion properties, and soft products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

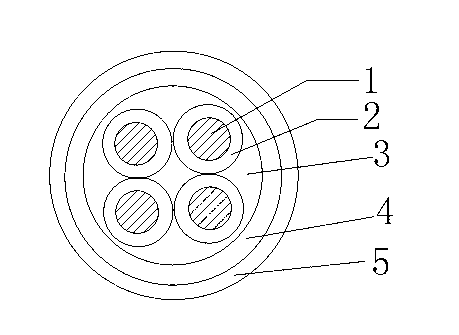

[0012] like figure 1 As shown in the figure, a ceramized silicon rubber insulated fireproof cable according to the present invention includes a cable core, the cable core is formed by twisting a plurality of insulated wire cores, the gaps in the cable core are filled with flame retardant filler 3, and the cable core is filled with flame retardant filler 3 The core is extruded with an armor layer 4, and the outermost layer is extruded with a low-smoke and non-toxic plastic material outer sheath 5. The insulated wire core is composed of a conductor 1 and a ceramic silicon rubber insulating layer 2 wrapped around the conductor 1 .

[0013] Raw material selection and production process of the present invention:

[0014] 1) Cable conductor:

[0015] It is formed by twisting multiple strands of copper wires to the opposite stranded conductor structure. After twisting, the outer diameter is close, the twisting rate is the same, and the twisting direction is opposite, so this struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com