Method and device for testing fatigue of car thrust rod component

A fatigue test and test device technology, applied in the field of verifying its fatigue performance, can solve the problem of not involving the loading fatigue test of thrust rod components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

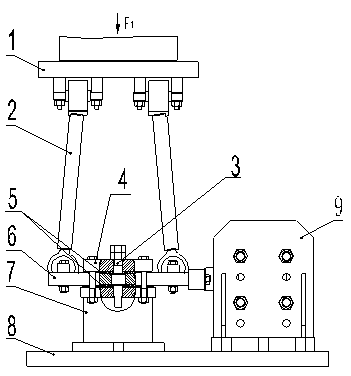

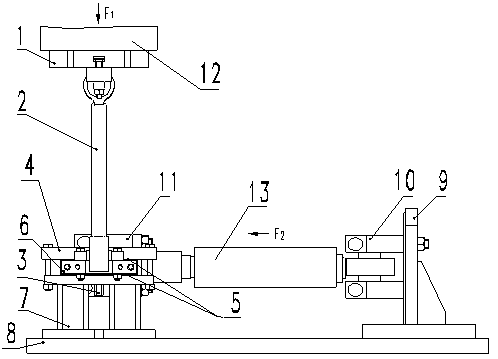

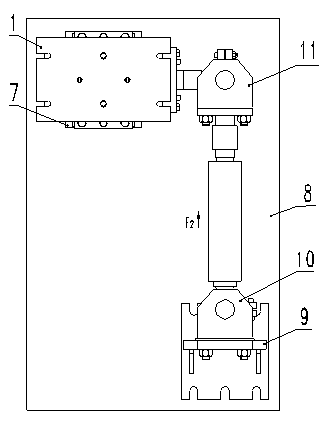

[0029]A fatigue test device for an automobile thrust rod assembly, comprising an upper test platform 1, the thrust rod assemblies 2 to be tested are installed in pairs, respectively connected to the upper test platform 1 through front-end ball joints, and a vertical actuator 12 passes through the upper test platform 1 Apply longitudinal tensile and compressive loads to the thrust rod assembly 2; it includes a rotary table 6, and the upper and lower sides of the rotary table 6 are provided with circular grooves, and polyethylene discs 5 or other smooth and wear-resistant materials are placed in the grooves, which are respectively connected with the upper and lower wear-resistant materials. The grinding plate 4 is in contact with the wear-resistant base 7, and the rear end ball joints of the thrust rod assembly 2 to be tested are respectively fixed on both sides of the rotary table 6; a lower test platform 8 is included, and the wear-resistant base 7 is fixed on the lower test pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com