Automatic rock drilling device special for tunnel excavation

A technology of rock drilling equipment and tunnel excavation, which is applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of researchers' body, safety injury, long rock drilling time, small arm size, etc., to improve rock drilling efficiency , The effect of improving rock drilling quality and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described below in conjunction with specific embodiment;

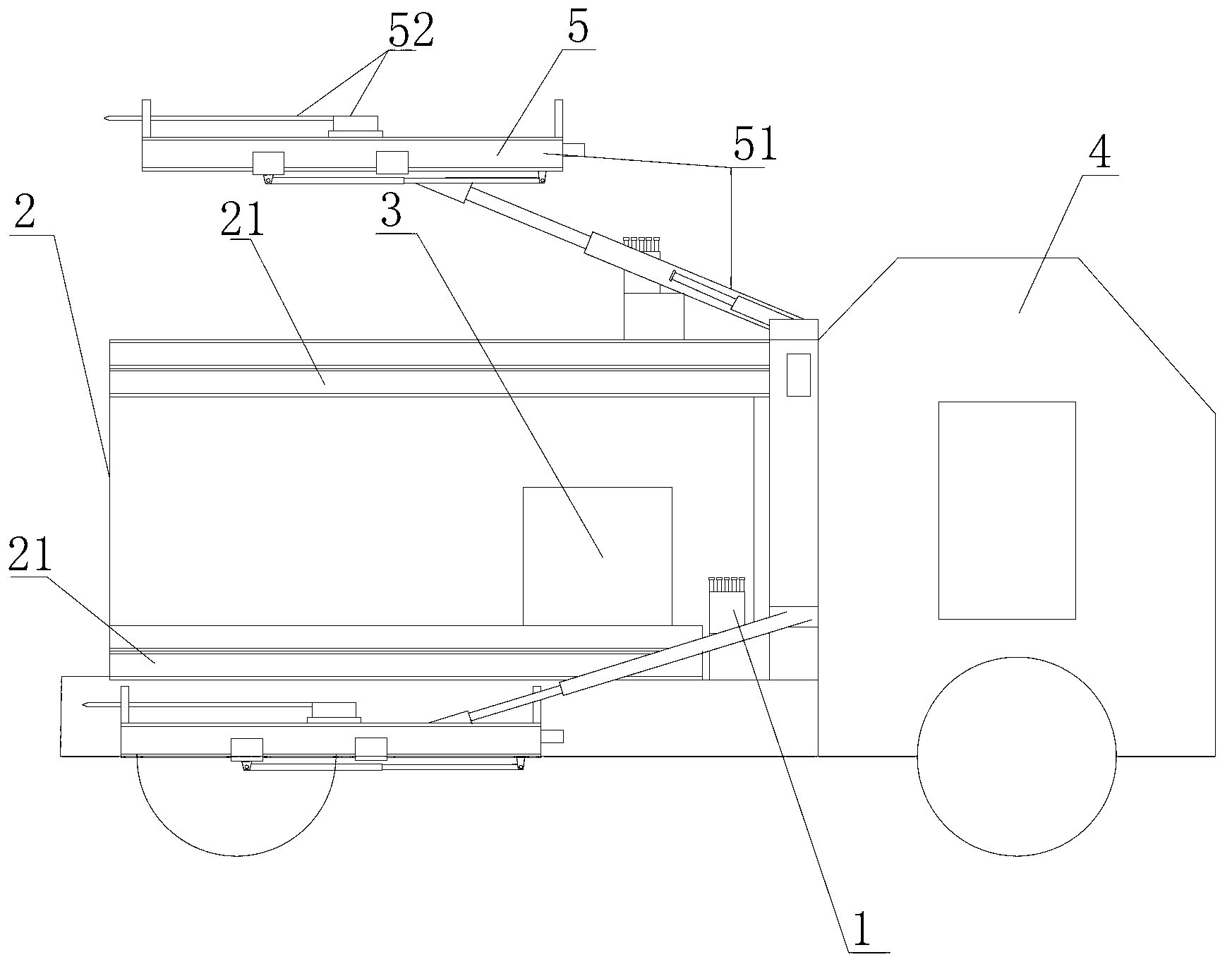

[0022] Such as figure 1 Shown:

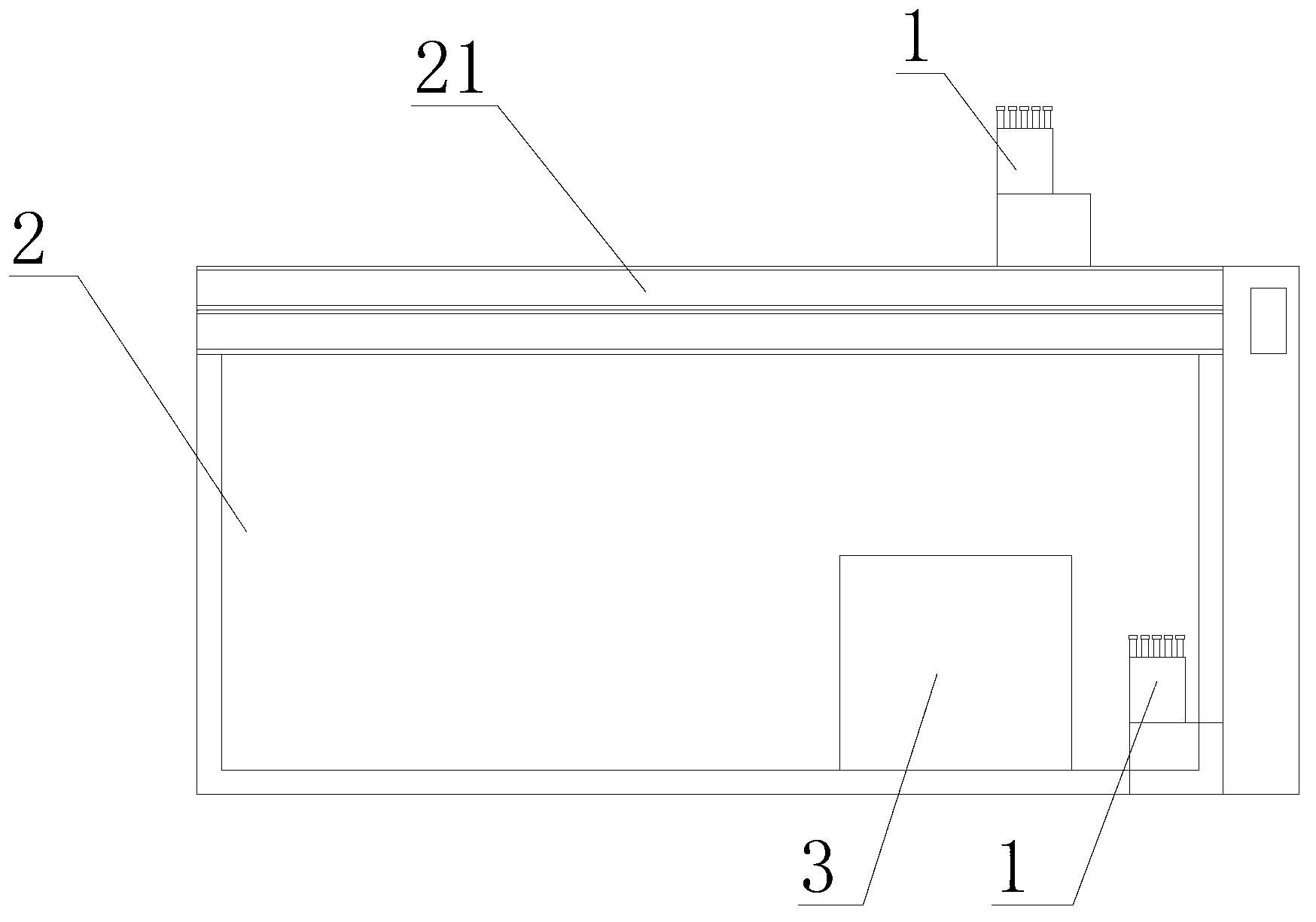

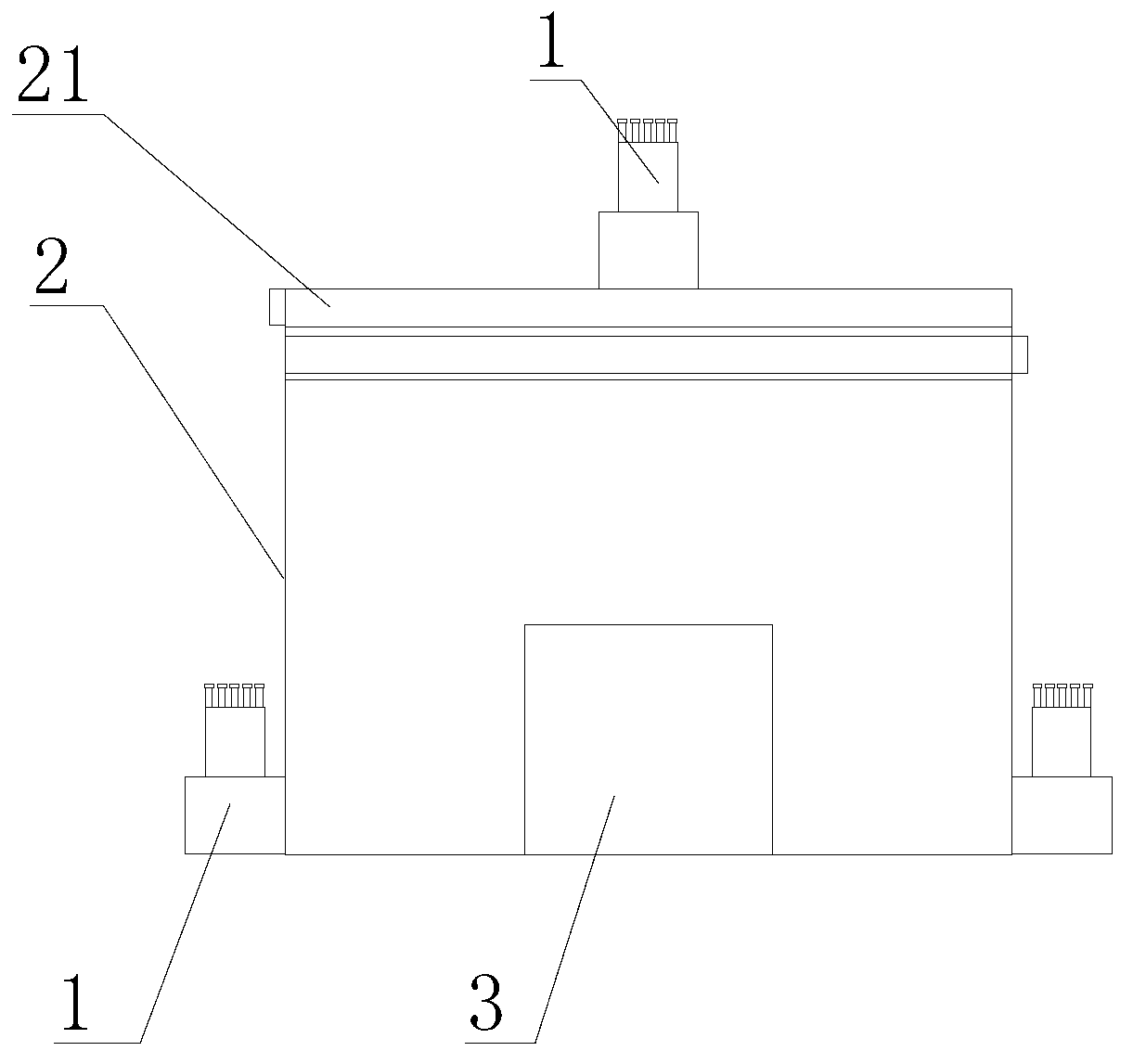

[0023] It includes a console 1, a support frame 2, a power unit 3, a movable carrier 4, and rock drilling equipment 5. The support frame is installed on the carrier, and the power unit, console, and rock drilling equipment are installed on the support frame. The power unit is connected to the rock drilling equipment through wires, and the console is respectively connected to the power unit and the rock drilling equipment through wires; the power unit is used to provide power for the console and the rock drilling equipment, and the console is used to control the rock drilling equipment. The support frame is used to carry the console, rock drilling equipment, and power device, and the support frame moves by being installed on the carrier.

[0024] The support frame is a square frame body, and at least one group of platforms 21 that can expand and contract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com