Method and equipment for inhibiting the formation of hydrogen sulfide in oil layer by steam flooding injection well

A technology for steam flooding and injection wells, which is applied in chemical instruments and methods, earth-moving drilling and production, wellbore/well components, etc. The effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

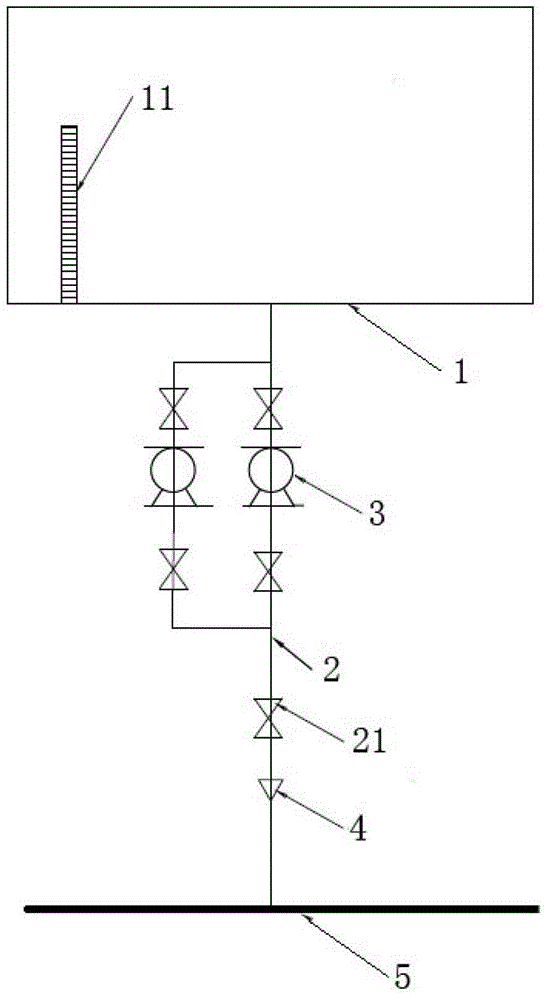

[0031] See figure 1 As shown, the steam flooding injection well of this embodiment suppresses the treatment liquid delivery equipment for producing hydrogen sulfide in the oil layer, including:

[0032] A processing liquid storage container 1 for accommodating the processing liquid, in which a liquid level gauge 11 is arranged;

[0033] A treatment liquid delivery pipeline 2, one end of which is connected to the treatment solution storage container 1, and the other end is used to communicate with the steam injection pipeline 5 of the steam flooding injection well; a necessary valve 21 is also arranged on the delivery pipeline;

[0034] Two plunger pumps 3 arranged side by side on the delivery pipeline;

[0035]Moreover, a check valve 4 is provided on the delivery pipeline at the outlet of the plunger pump.

[0036] In Well Jin 45-024-K24, the steam injection rate is 108 tons / day, or 75 kg / min.

[0037] Sodium nitrate, sodium hydroxide, and demineralized water are prepared o...

Embodiment 2

[0042] The steam injection rate of Well Jin 45-024-K26 is about 102 tons / day, or about 71 kg / min.

[0043] Sodium nitrate, sodium hydroxide, fluorocarbon surfactant TF3721 (purchased from Shanghai Laiguo Chemical Co., Ltd.), demineralized water are prepared on-site as a treatment agent solution, wherein the mass concentration of sodium nitrate is 0.5%, and the mass concentration of sodium hydroxide is 0.5%. , Fluorocarbon surfactant TF3721 mass concentration 1%.

[0044] The treatment agent solution prepared on site is injected with a high temperature and high pressure drip pump at a rate of 70ml / min with steam. Corresponding to the production well Jin 45-024-K25, the casing hydrogen sulfide concentration before comparison is 750mg / m 3 , the pressure of the injection well is 7.0MPa, the daily oil production of the production well is 1.1 tons, and after 40 days of injection, the concentration of hydrogen sulfide in the casing is 100mg / m 3 , after 60 days of injection, the con...

Embodiment 3

[0046] The steam injection rate of Jin 45-023-K260 well is about 104 tons / day, or about 72 kg / min.

[0047] Nickel nitrate, sodium hydroxide, and demineralized water are prepared on-site as a treatment agent solution, wherein the mass concentration of nickel nitrate is 0.8%, and the mass concentration of sodium hydroxide is 0.8%.

[0048] The treatment agent solution prepared on site is injected with a high temperature and high pressure drip pump at a speed of 90ml / min with steam. Corresponding to the production well Jin 45-23-K261 well, the concentration of hydrogen sulfide in the casing before comparison is 1150mg / m 3 , the daily oil production of the production well is 1.4 tons, the viscosity of degassed crude oil at 50°C is 10775MPa.S, and after 50 days of injection, the concentration of hydrogen sulfide in the casing is 210mg / m 3 , after 70 days of injection, the concentration of hydrogen sulfide is 0mg / m 3 , the daily oil production of the production well is 2.5 tons, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com