Anti-theft lock cylinder

An anti-theft lock core and inner core technology, applied in the field of locks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

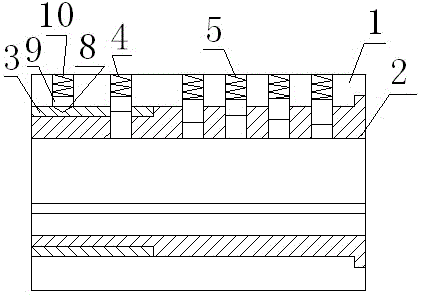

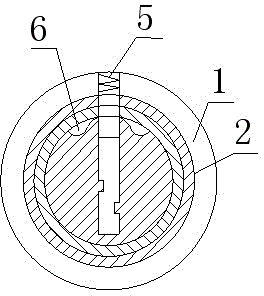

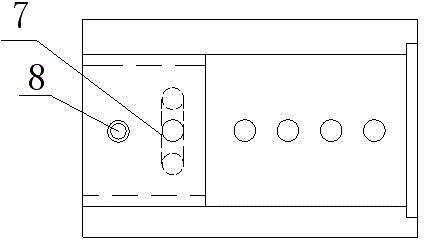

[0018] The utility model is as figure 1 , figure 2 , image 3 shown.

[0019] An anti-theft lock cylinder, comprising an outer lock core 1 and an inner lock core 2, the inner lock core 2 is provided with a pin hole, the pin hole is provided with a pin, and a spring 5 on the lock core is used in cooperation with the outer lock core 1. The outer circle of the lock inner core 2 is provided with a cylindrical step, and the cylindrical step is covered with a circular ring sleeve 3; the cylindrical step is provided with a marble hole, and the circular ring sleeve 3 is also provided with a matching marble hole 7, and the marble hole 7 is equipped with The marbles are in contact with the outer lock core 1 through the spring 4 on the ring sleeve; blind holes are provided at ±35°~40° on both sides of the marble hole on the cylindrical step through the arc.

[0020] The cylindrical step on the outer circle of the lock inner core 2 can also be set at any position in front of or in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com