Novel long rod sling

A long pole and new type of technology, applied in the field of spreaders, can solve the problems of increasing the difficulty of picking up items, the short distance between the lifting point and the hanging point on the top of the spreader, and the vertical height cannot always be consistent, so as to ensure the work Reliability, elimination of accident hazards, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

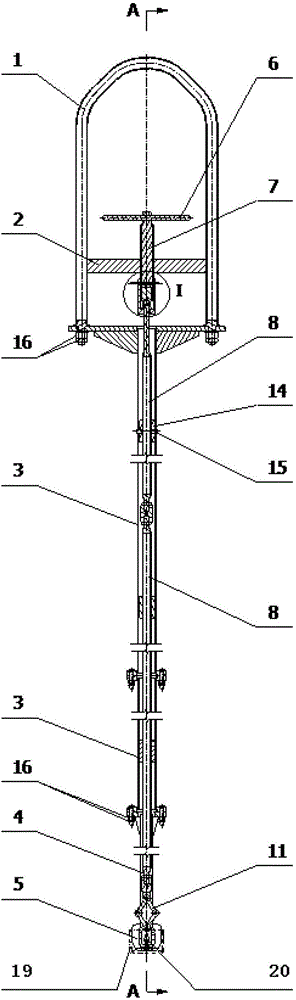

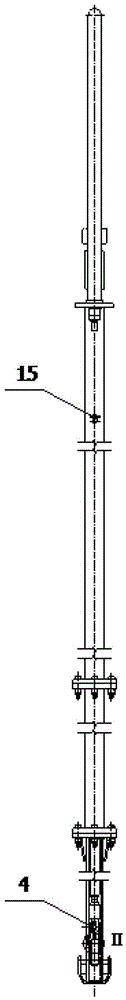

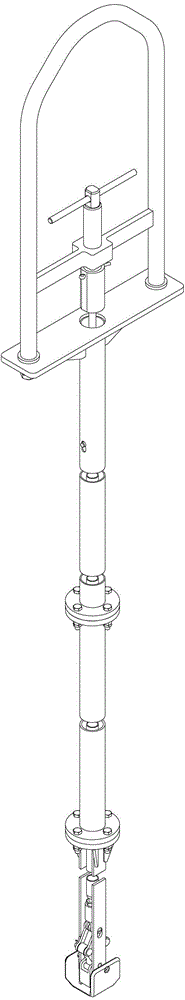

[0033] The main structure of the long rod spreader of the present invention is composed of a suspension ring, a gripper assembly and a connecting pipe. The gripper assembly includes a bracket and a gripper arranged on the bracket. Among them, the function of the lifting ring is to hook the hook of the lifting equipment (such as the crane in the factory building), and the function of the claw assembly is to grab the object to be hoisted; the connecting pipe is a long rigid pipe, and the specific length can be determined according to The actual application is determined, the connecting pipe is vertically arranged, and its upper and lower ends are fixedly connected with the suspension ring and the bracket respectively. The claws are connected, and the claws are closed or opened with the up and down movement of the transmission rod. In the present invention, since a long rigid connecting pipe is arranged between the suspension ring and the gripper assembly, and the driving mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com