Necking detection control method in consumable electrode electric arc welding

A consumable electrode and arc welding technology, which is applied in the necking detection and control field of consumable electrode arc welding, can solve the problems such as the inability to properly adjust the necking detection reference value and reduce the sensitivity, so as to increase the suppression of spatter generation, reduce the sensitivity, The effect of increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

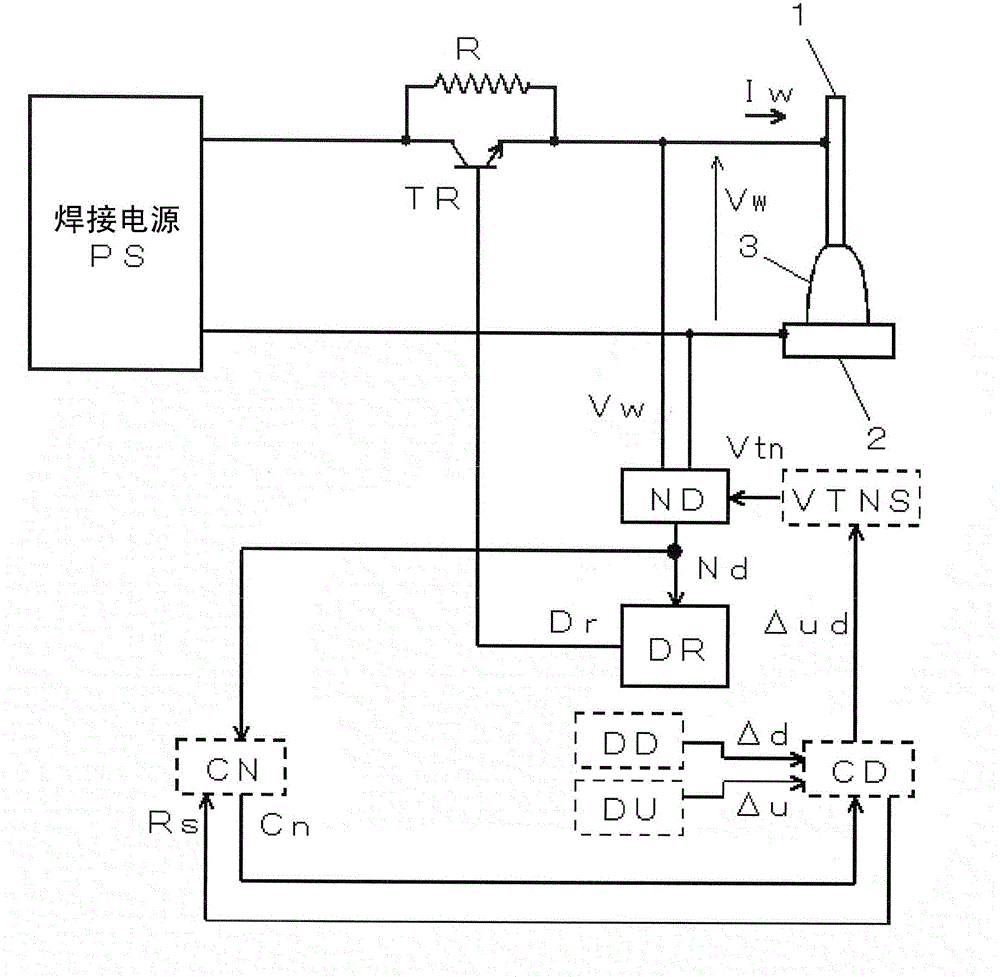

Embodiment approach 1

[0042] In the constriction detection control method according to Embodiment 1 of the present invention, the constriction detection time Tn is detected every short circuit, and when the constriction detection time Tn is equal to or less than the lower limit time Lt, the constriction detection time Tn is subtracted from the counter value Cn. 1. When the constriction detection time Tn is greater than the upper limit time Ht, 1 is added to the counter value Cn, and when the counter value reaches the negative reference value Lc, the constriction detection reference value Vtn is decreased by the decrease value Δd, And reset the counter value Cn to 0, when the counter value Cn reaches the positive reference value Hc, increase the constriction detection reference value Vtn by the increment value Δu, reset the counter value Cn to 0, and continue welding Correction of the aforementioned constriction detection reference value Vtn. Hereinafter, Embodiment 1 will be described.

[0043] ...

Embodiment approach 2

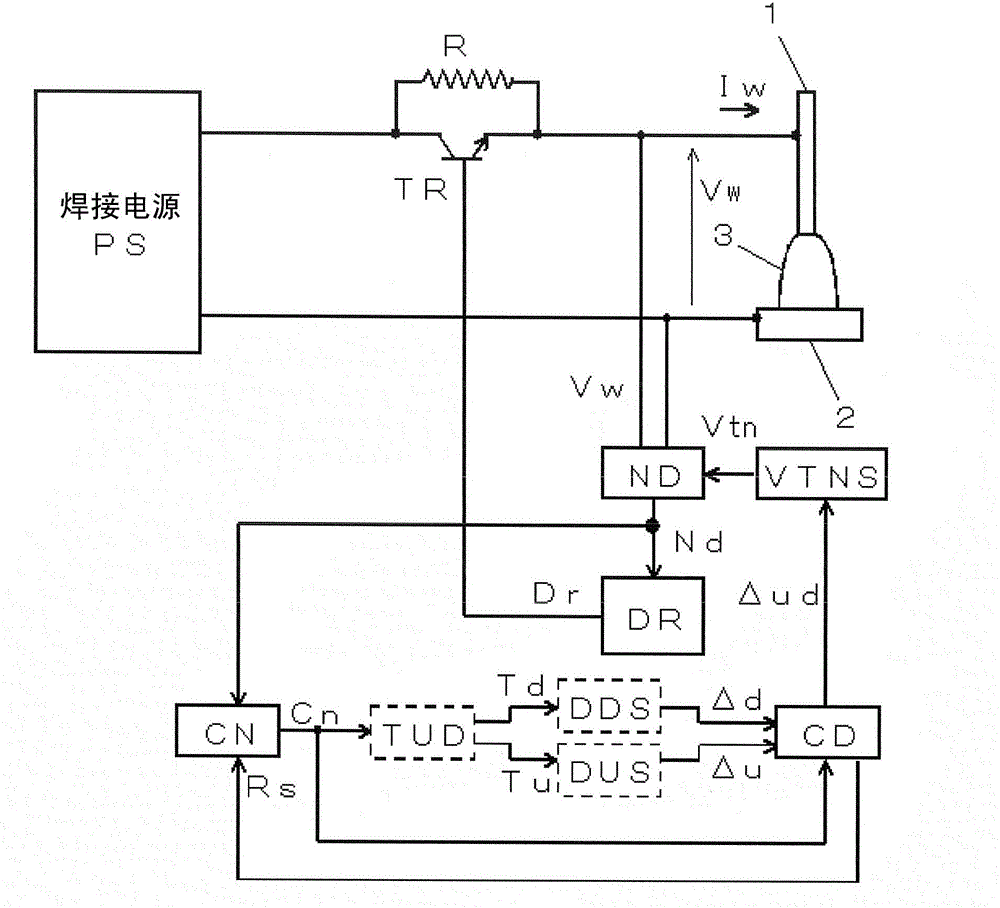

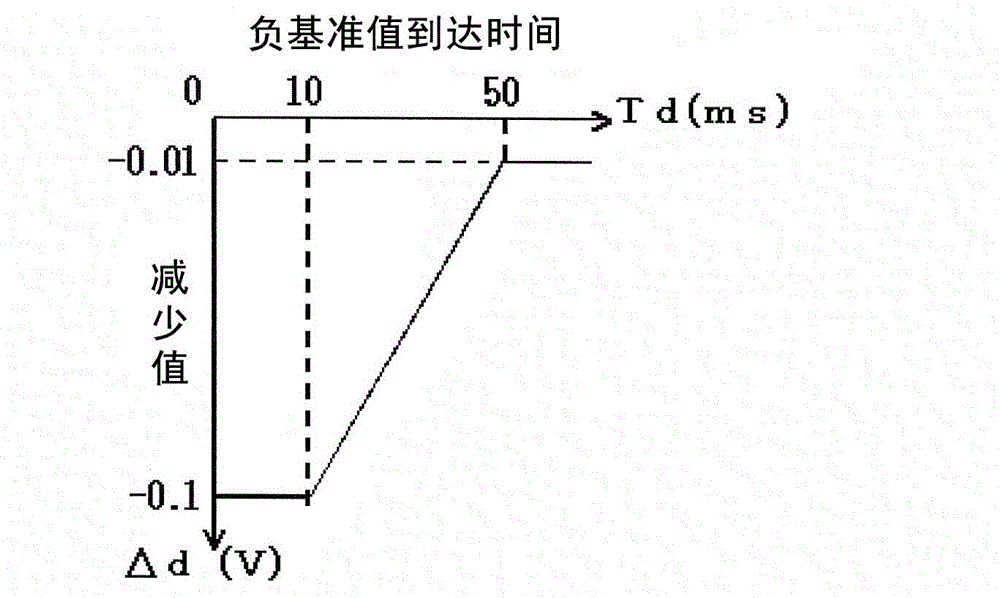

[0056] In the constriction detection control method according to Embodiment 2 of the present invention, the above-mentioned decrease value Δd is set based on the negative reference value from the time when the above-mentioned counter value Cn is reset to 0 until reaching the above-mentioned negative reference value Lc. The arrival time Td is changed, and the above-mentioned increment value Δu is changed according to the positive reference value arrival time Tu from the time when the above-mentioned counter value Cn is reset to 0 to the above-mentioned positive reference value Hc. Hereinafter, Embodiment 2 will be described.

[0057] figure 2 It is a block diagram of a welding device for carrying out the constriction detection control method of consumable electrode arc welding according to the second embodiment. Should figure 2 with the above Image 6 and figure 1 Correspondingly, the same code is given to the same block, and these explanations are omitted. figure 2 is...

Embodiment approach 3

[0064] In the constriction detection control method according to the third embodiment of the present invention, in addition to the above-mentioned first and second embodiments, the constriction occurs within a predetermined period Ti from the time point when the previous short circuit was opened and the arc regenerated. In the event of a short circuit, the counter value Cn is not increased or decreased based on the constriction detection time Tn of the short circuit. Hereinafter, Embodiment 3 will be described.

[0065] Figure 4 It is a block diagram of a welding device for implementing the constriction detection control method of consumable electrode arc welding according to Embodiment 3 of the present invention. Should Figure 4 and Image 6 and figure 1 Correspondingly, the same code is given to the same block, and these explanations are omitted. Figure 4 is: in figure 1 The short circuit / arc discrimination circuit SA and the double short circuit discrimination ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com