Device for measuring material refractive index temperature coefficient under low temperature based on minimum deviation angle method

A technology of minimum deflection angle method and refractive index temperature, which is applied in the measurement of phase influence characteristics, etc., can solve the problems of error sensitivity, total reflection, measurement failure, etc., and achieve the effect of improving measurement accuracy, simple components, and avoiding failure to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

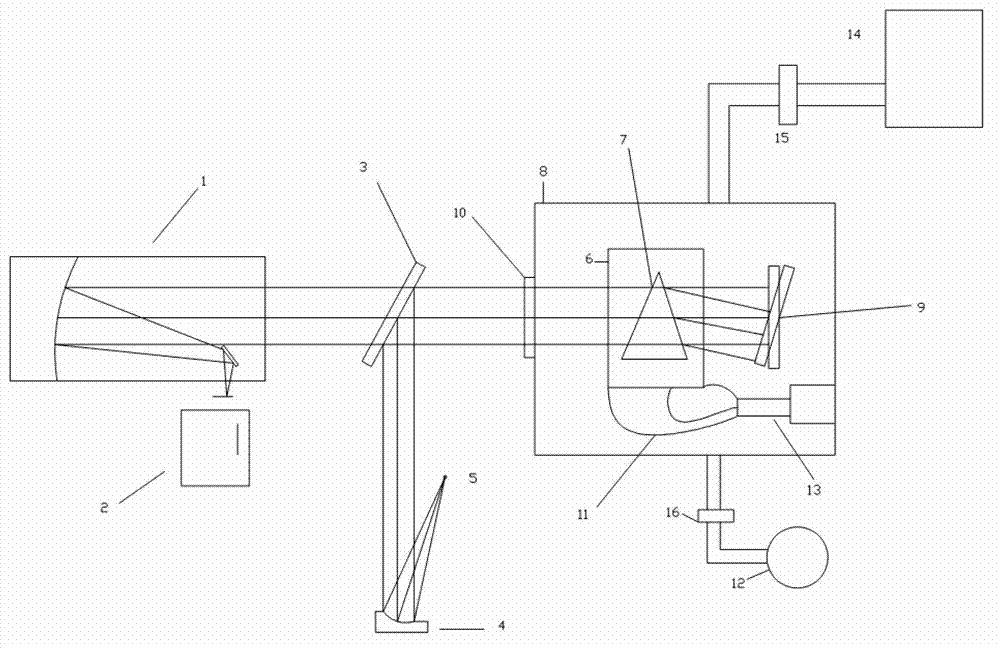

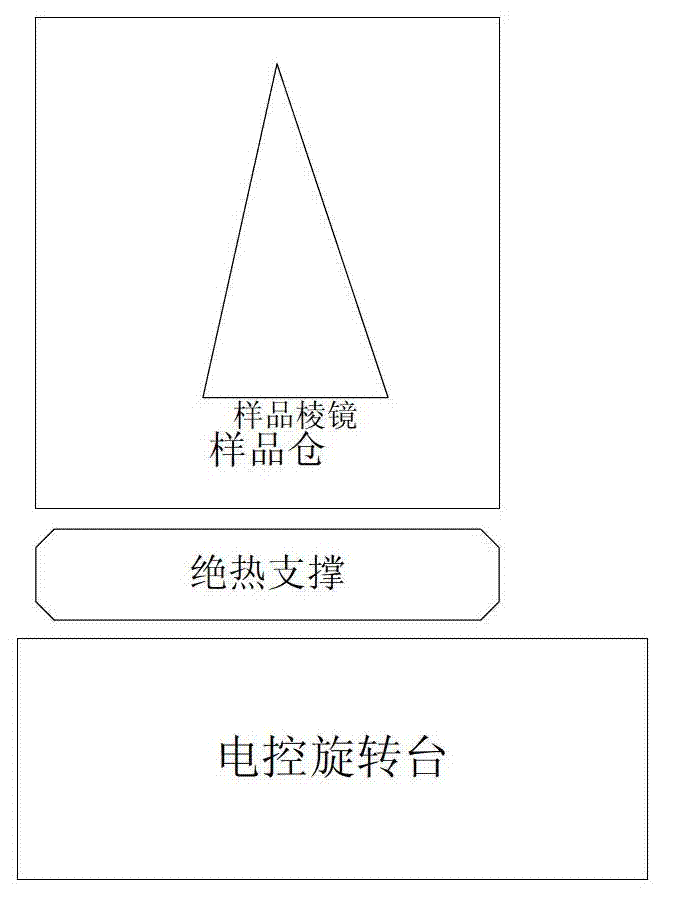

[0024] The present invention will be described in detail below with reference to the drawings and specific embodiments.

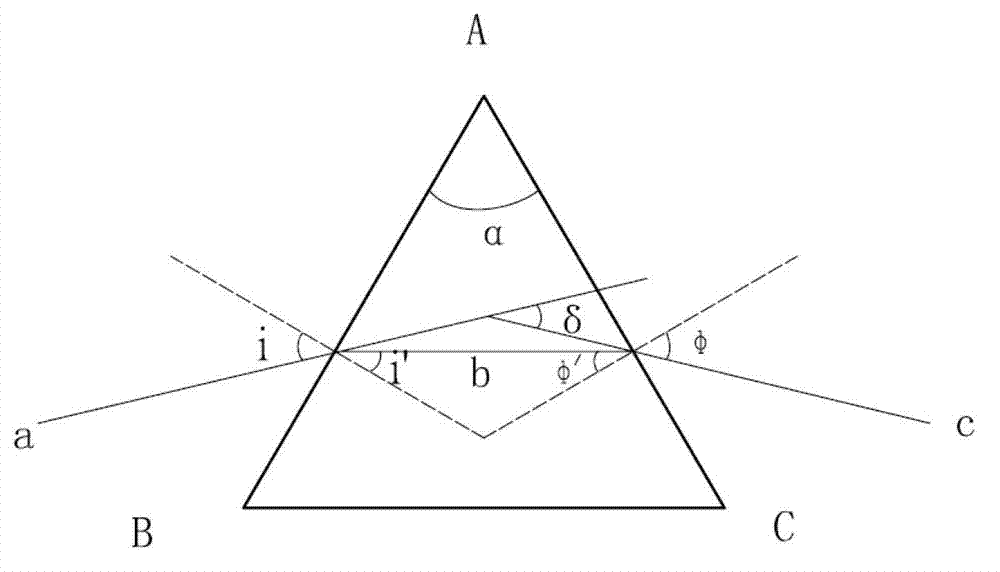

[0025] A device for measuring the temperature coefficient of the refractive index of a material at low temperatures. Its principle is the minimum deflection angle method. The minimum deflection angle method to determine the refractive index of materials technology, figure 1 It is shown as the working principle diagram. When the light is incident on the AB surface of the prism at the incident angle i and then successively refracted by the two optical surfaces AB and AC of the prism, The angle shoots from the AC side. The angle δ between the outgoing light and the incident light is called the deflection angle. For a given prism, the value of the deflection angle δ varies with the incident angle i. When the incident angle i is equal to the exit angle φ, the deflection angle δ will reach the minimum value δ 0 ,δ 0 It is called the minimum deflection angle. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com