Tunnel inverted arch sliding formwork concrete lining steel trolley

A technology of steel formwork trolley and sliding form, which is applied in the field of trolleys, can solve problems such as inability to fully vibrate and not yet achieve satisfactory results, and achieve the effect of reducing construction economic burden, reducing mutual interference, and perfect construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

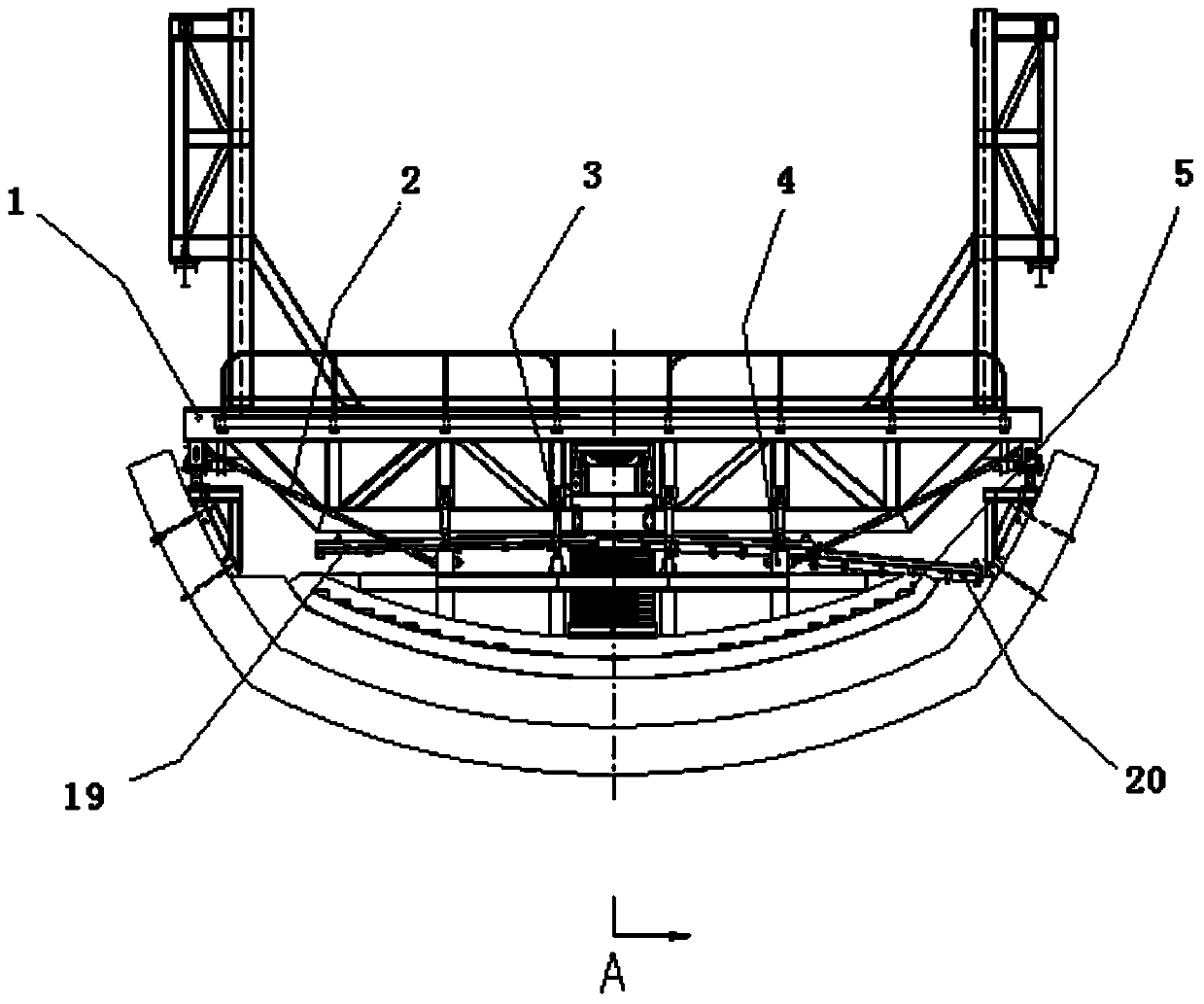

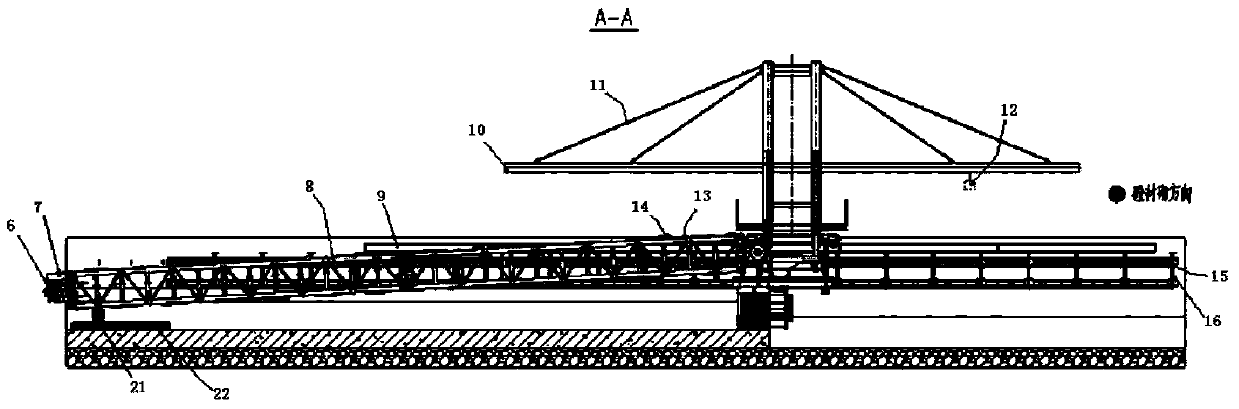

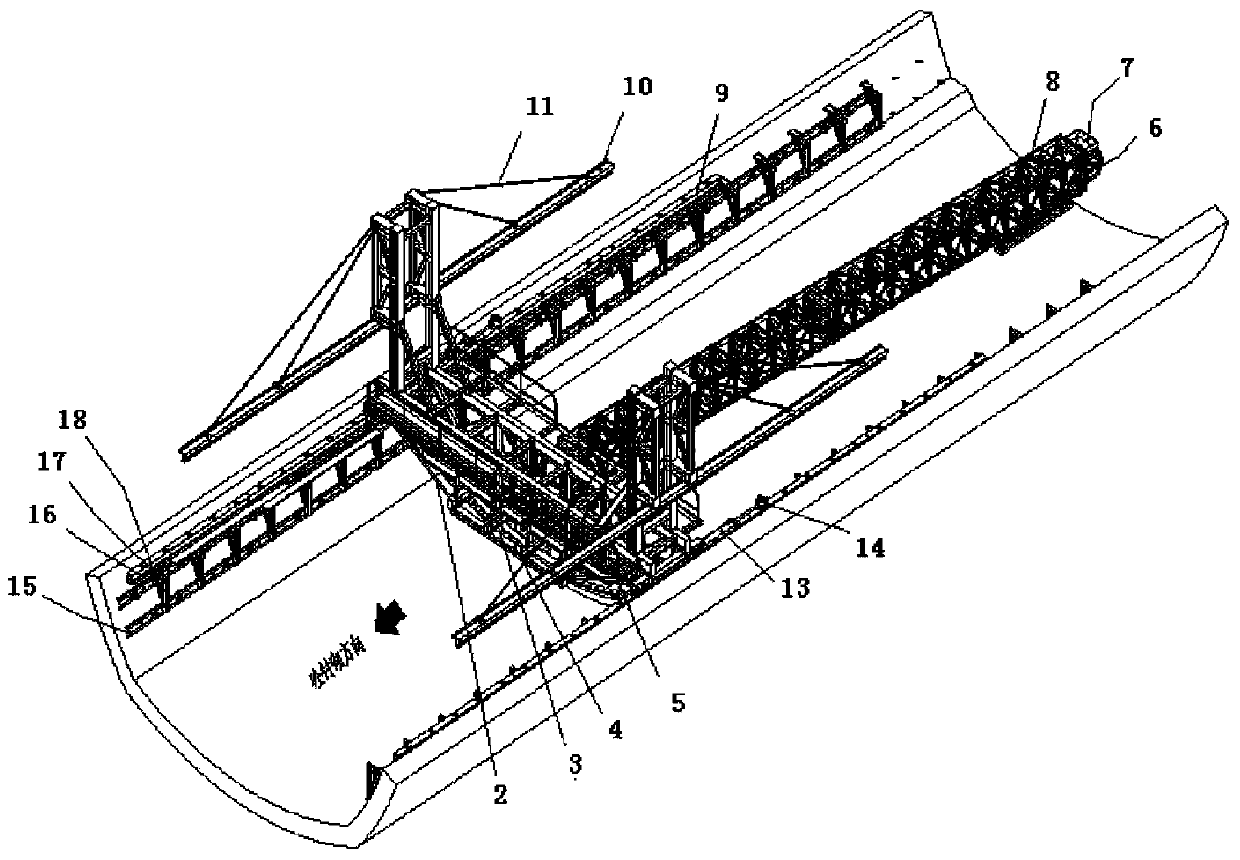

[0027] The tunnel inverted arch slipform concrete lining steel form trolley of the present embodiment, such as Figure 1-3 As shown, it includes a sliding template 5, a main frame 1, an adjustment jack 3, and a deviation correction adjustment rod 2; a bottom deviation correction frame 4 is provided on the sliding formwork 5, and the bottom deviation correction frame 4 connects with the main frame through the adjustment jack 3 and the deviation correction adjustment rod 2. 1 is connected; the middle part of main frame 1 is provided with frame, is provided with the main belt conveyor 8 that is used to convey concrete and the sub-belt conveyor 19,20 that disperses the concrete on the main belt conveyor both sides of equipment in the framework; A feed hopper 7 is arranged, and a driven drum 6 is provided below the feed hopper 7, and a driven traveling wheel 21 and a travel track 22 that provide tail support for the main belt conveyor 8 are provided below the frame.

[0028] The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com