Built-in slide way assembly of crib

A technology of cribs and slides, which is applied in the direction of children's furniture, household appliances, applications, etc., can solve the problems of plastic parts breakage, shrapnel sticking, etc., and achieve the effect of reducing interference and friction, and avoiding the effect of easy aging and sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

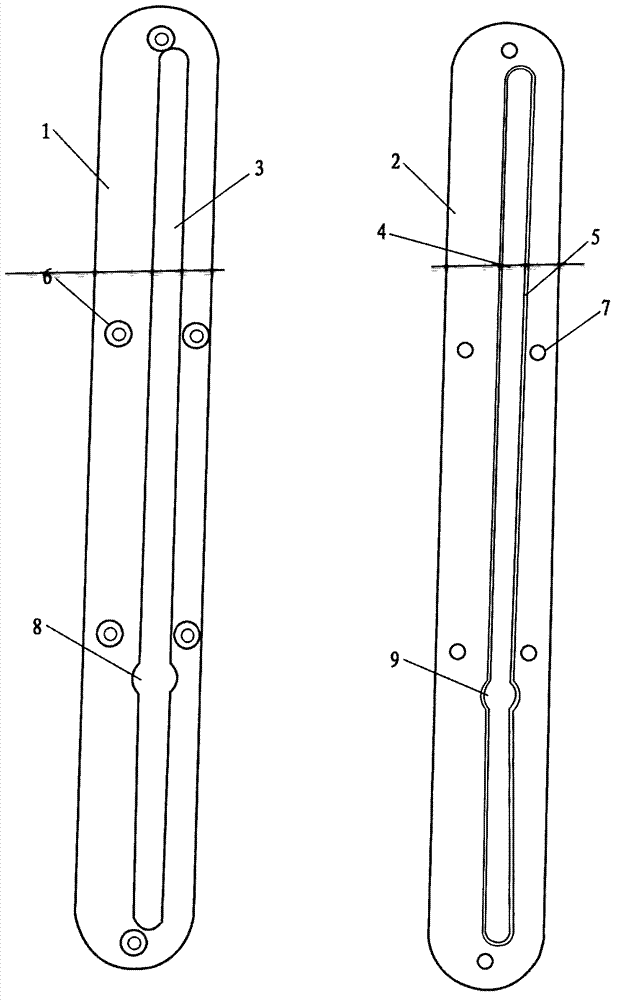

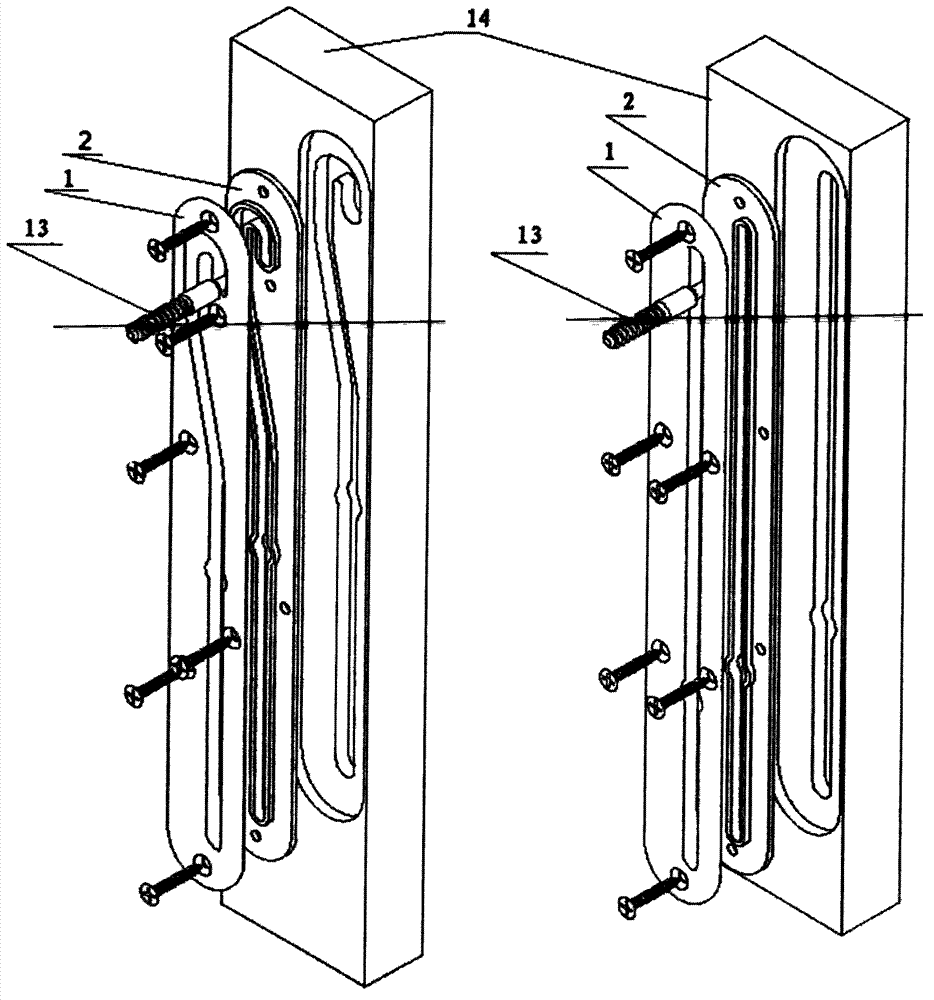

[0013] Example 1 as figure 1 As shown, a built-in slideway assembly of a crib includes a body 1 and a liner 2, a first slideway 3 is provided on the body, and a second slideway 4 overlapping with the first slideway is provided on the liner; An upwardly protruding flange 5 is provided on the edge of the second slideway 4 ; the flange is attached to the inner edge of the first slideway 3 .

[0014] The main body and the inner lining are provided with fixing holes through both, which are the main body fixing holes 6 and the inner lining fixing holes 7 respectively. Through the fixing hole, the built-in slideway assembly of the crib is fixed on the upright post of the crib.

[0015] The first slideway 3 and the second slideway 4 are provided with insertion openings, which are body insertion openings 8 and lining insertion openings 9 respectively, and the insertion openings are used for inserting sliding cores.

[0016] The inner liner 2 is made of nylon material.

[0017] Put t...

Embodiment 2

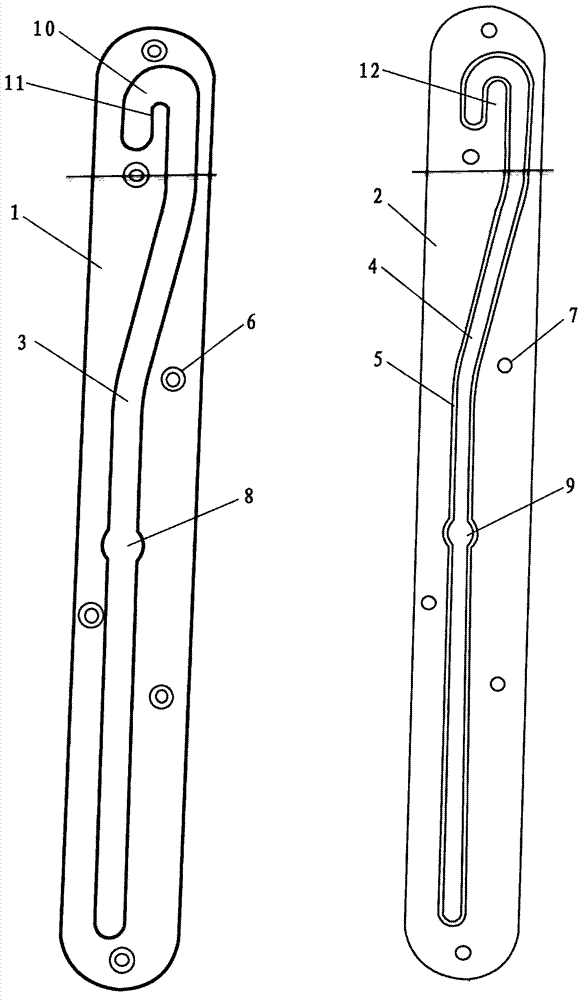

[0018] Example 2 as figure 2 As shown, a built-in slideway assembly of a crib includes a body 1 and a liner 2, a first slideway 3 is provided on the body, and a second slideway 4 overlapping with the first slideway is provided on the liner; An upwardly protruding flange 5 is provided on the edge of the second slideway 4 ; the flange is attached to the inner edge of the first slideway 3 .

[0019] The main body and the inner lining are provided with fixing holes through both, which are the main body fixing holes 6 and the inner lining fixing holes 7 respectively. Through the fixing hole, the built-in slideway assembly of the crib is fixed on the upright post of the crib.

[0020] The first slideway 3 and the second slideway 4 are provided with insertion openings, which are body insertion openings 8 and lining insertion openings 9 respectively, and the insertion openings are used for inserting sliding cores.

[0021] The detour 10 at the upper end of the first slide 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com