Lifting doors with movable leaf guides

A technology for lifting doors and door leaves, which is applied to the suspension of wing leaves, blinds/movable grilles, windows/doors, etc. It can solve the problems that the door leaf cannot move in smoothly, is not suitable for fast-moving operation, and cannot ensure connection, etc. , to achieve reliable and fast moving operation, low structural complexity and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

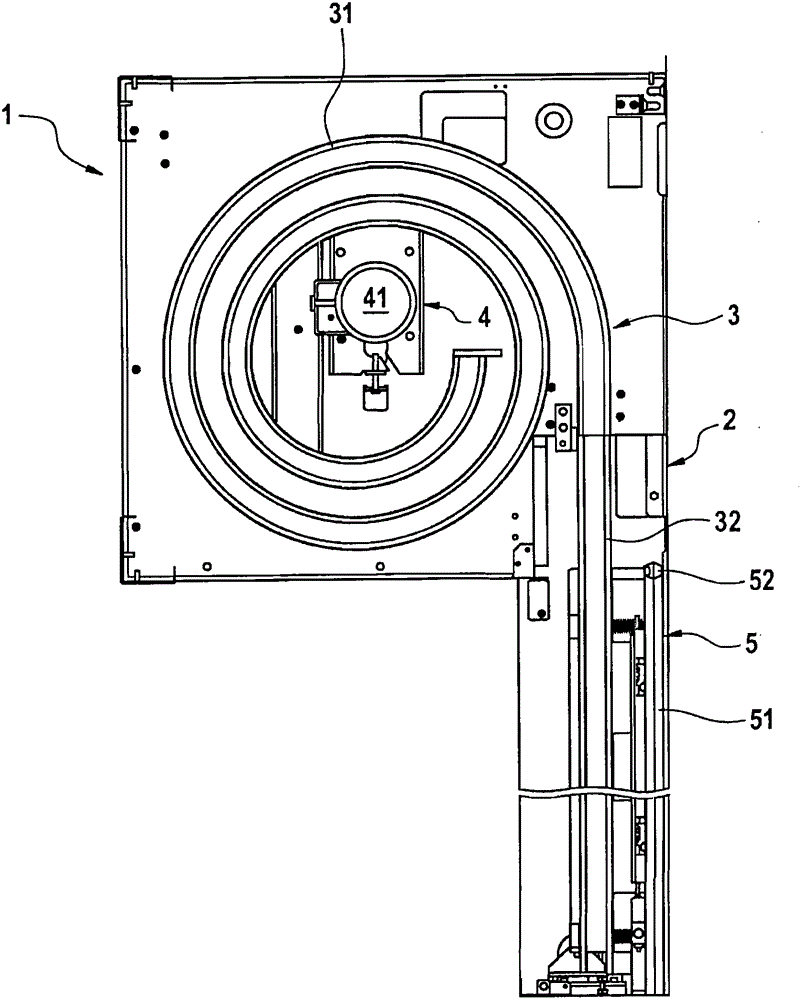

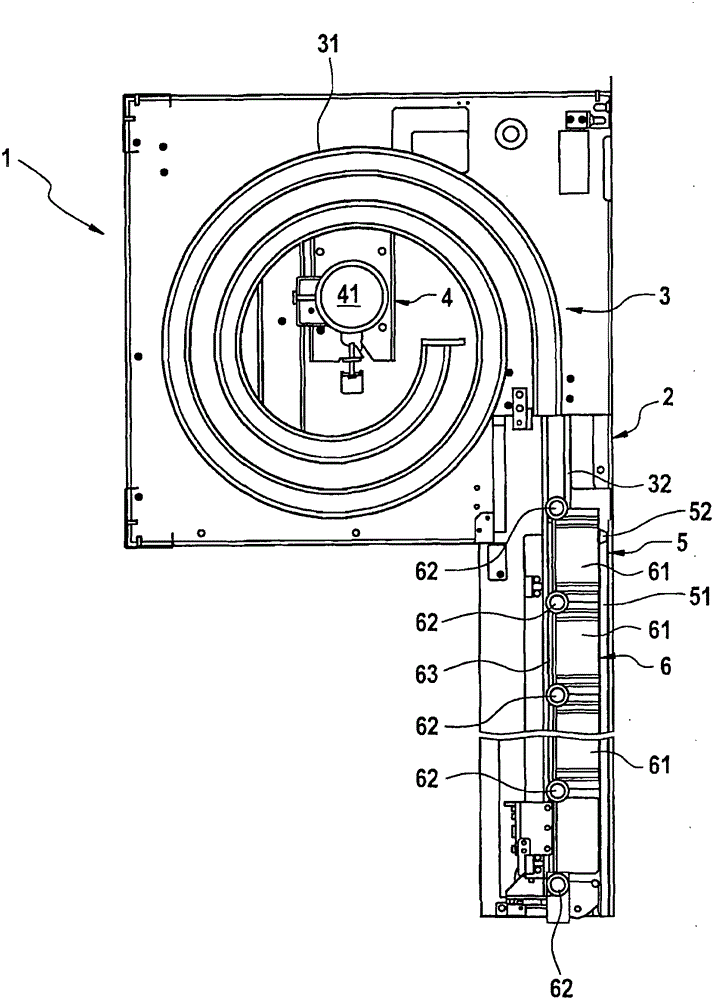

[0048] according to figure 1 In the figure, the lifting door 1 comprises a frame 2 with a guide rail 3 for the door leaf, but the guide rail 3 is not shown in this figure. figure 1 Shown is a view of the frame 2 on the left hand looking out from the door opening. In the following descriptions, in most cases, only the area on one side of the door will be discussed, while the other side of the door opening presents the frame settings including the guide rails, etc. formed according to the mirror image. The lift gate 1 also comprises a drive unit 4 comprising a motor 41 and a sealing device 5 .

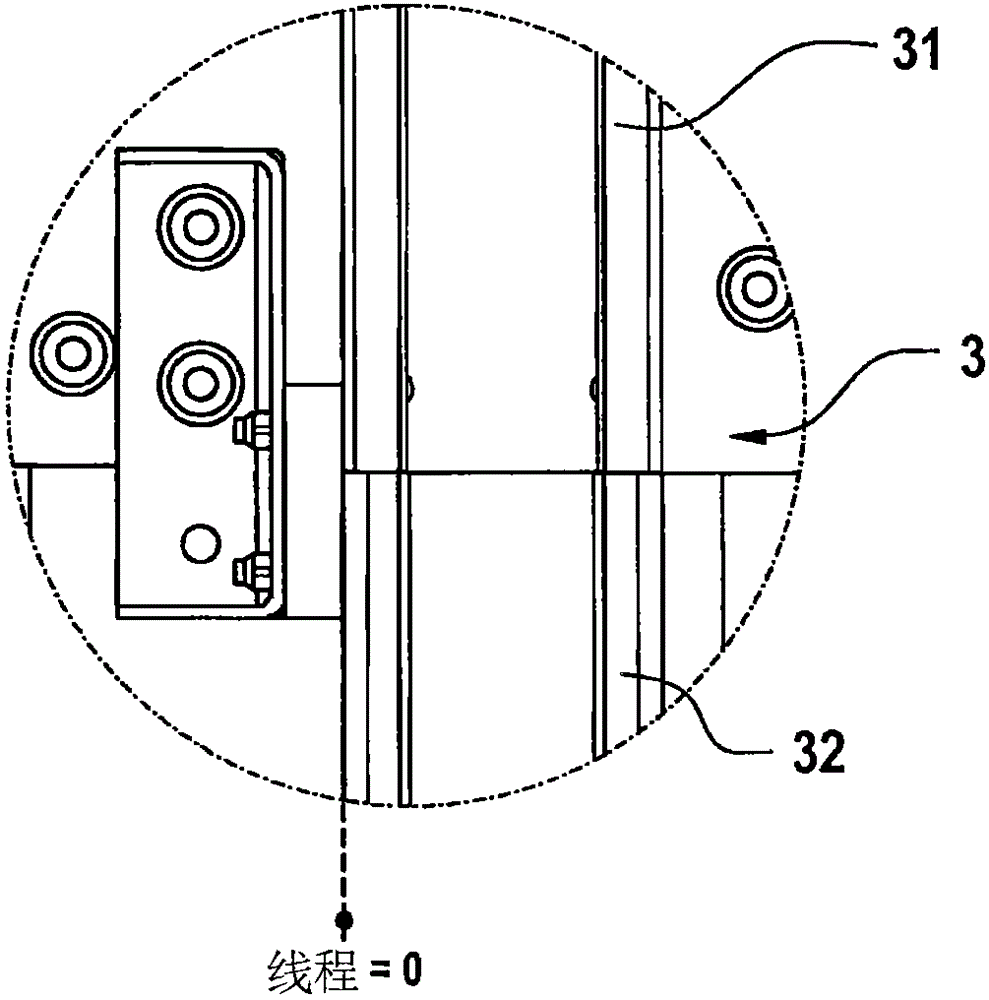

[0049] The guide rail 3 comprises a web portion 31 which, in the practical example, has the form of a helix. When the lift door 1 is in the open state, the door leaf is received therein in the form of a contactless coil in the region of the door web. The guide rail 3 also comprises a vertical portion 32 in which the door leaf assumes the closed state of the lift door 1 . At the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com