Fully-automatic production line of transformer

A fully automatic and transformer technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as production, low efficiency, prone to defective products, and low product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

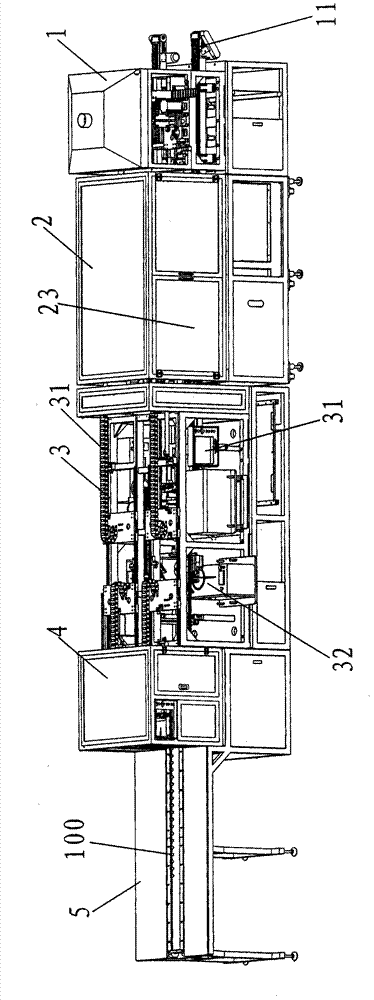

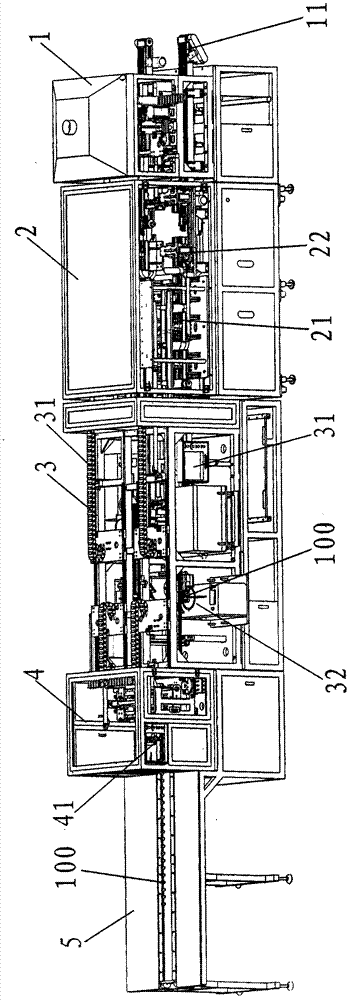

[0010] See Figure 1 to Figure 2 As shown: the present invention includes a feeding mechanism 1, a coil assembly mechanism 2, an assembly mechanism 3, a soldering mechanism 4, a product conveying platform 5, a feeding mechanism 1, a coil assembling mechanism 2, an assembling mechanism 3, a soldering mechanism 4, and a product conveying platform 5 in sequence The machine body is connected with each other, the conveyor belt 11 is installed in the feeding mechanism 1, the jig positioning table 21 and the coil assembly table 21 are arranged in the coil assembly mechanism 2, the operation panel 31 is arranged on the assembly mechanism 3, and the stitch feeding mechanism 4 is provided in the soldering mechanism 4. The spot welding station 41 of spot welding, the feeding mechanism 1, the coil assembly mechanism 2, the assembly mechanism 3, the solder mechanism 4, and the product conveying platform 5 are connected by a conveying mechanism.

[0011] The coil assembly mechanism 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com