Device for measuring ratio of specific heat capacity of gas

A technology of specific heat capacity ratio and gas, which is applied in the field of devices for measuring the specific heat capacity ratio of gases, can solve the problems of high cost, low measurement accuracy, complex structure, etc., and achieves the effects of easy operation, small error in measurement results, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

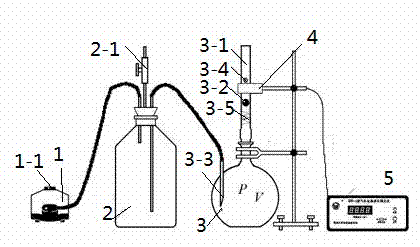

[0014] Such as figure 1 As shown, the existing device for measuring the specific heat capacity ratio of gas generally includes a micro air pump 1, a buffer bottle 2, a flask 3, a photoelectric gate 4 and a period measuring instrument 5 connected in sequence, wherein a precision glass tube 3-1 is inserted above the flask 3 , a steel ball 3-2 is placed in the precision glass tube 3-1; the diameter of the steel ball 3-2 is about 0.01mm smaller than the inner diameter of the precision glass tube 3-1, and it can move freely up and down in the precision glass tube 3-1. There is a small hole on the side of 3-2, and a narrow-mouthed glass tube 3-3 is inserted, through which the gas to be measured can be injected into the flask.

[0015] In order to compensate the attenuation of the amplitude of the steel ball 3-2 caused by gas damping, a small pressure airflow is always injected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com