Butterfly plate of butterfly valve

A butterfly plate and butterfly valve technology, which is applied to lift valves, valve devices, engine components, etc., can solve the problems of affecting valve sealing effect and large deformation of the butterfly plate, and achieve the effect of small irregular deformation and excellent sealing effect.

Inactive Publication Date: 2012-11-14

扬州罗克特种阀门有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

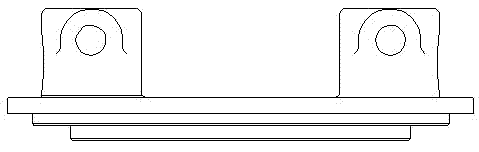

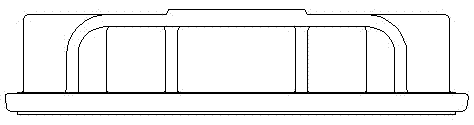

[0002] like figure 1 , 2 As shown, the structure of the traditional butterfly plate is generally truss type or flat plate type. The cross-sectional geometry of these two structures is different, and the deformation of the butterfly plate when it is stressed is large, which affects the sealing effect of the valve.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

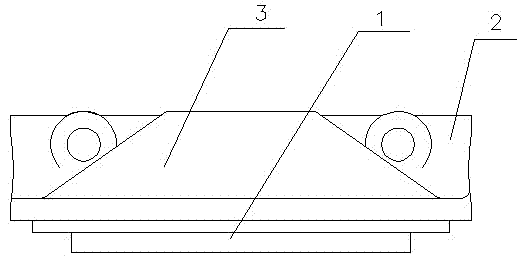

[0009] Such as image 3 As shown, the present invention includes a valve disc 1 and a valve shaft seat 2 for penetrating the valve shaft, the valve shaft seat 2 is fixed on one side of the valve disc 1, and the valve disc 1 on the side where the valve shaft seat 2 is fixed is connected with The conical frustum member 3, the large circular surface of the conical frustum member 3 is integrally connected with the valve flap 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a butterfly plate of a butterfly valve, and relates to the field of valve manufacturing. The butterfly plate comprises a valve clack and a valve shaft base used for penetrating through a valve shaft, wherein the valve shaft base is fixed on one side of the valve clack; and the butterfly valve is characterized in that the valve clack fixed on one side of the valve shaft base is connected with a cone round table constructional element, and a large circle surface of the cone round table constructional element is connected with the valve clack in an integral manner. According to the invention, each section is an equal geometric shape, therefore, the butterfly plate is of a constant strength design, the stress of each part is identical, the irregular distortion is small when the butterfly plate is in a temperature variation condition, and the butterfly plate has a good sealing effect when the valve is in a low temperature condition.

Description

technical field [0001] The invention relates to the field of valve manufacturing, in particular to a butterfly plate of a butterfly valve. Background technique [0002] Such as figure 1 , 2 As shown, the structure of the traditional butterfly plate is generally truss type or flat plate type. The cross-sectional geometry of these two structures is different, and the deformation of the butterfly plate when the force is applied is large, which affects the sealing effect of the valve. Contents of the invention [0003] The object of the present invention is to provide a butterfly plate of a butterfly valve with uniform stress and good deformation resistance. [0004] The technical solution to achieve the above purpose is: a butterfly plate of a butterfly valve, including a valve disc and a valve shaft seat for penetrating the valve shaft, the valve shaft seat is fixed on one side of the valve disc, and is characterized in that: the valve shaft seat A conical frustum member ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16K1/36F16K1/226

Inventor 李相臣何余

Owner 扬州罗克特种阀门有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com