Engine starting cam shaft assembly

A technology of engine starting and camshaft, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of poor finish of aluminum pins or soft iron pins, affecting the flexibility of centrifugal flying weights, and the reliability of centrifugal flying weights Poor quality and other problems, to achieve the effect of saving space and materials, conducive to controllability, and conducive to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

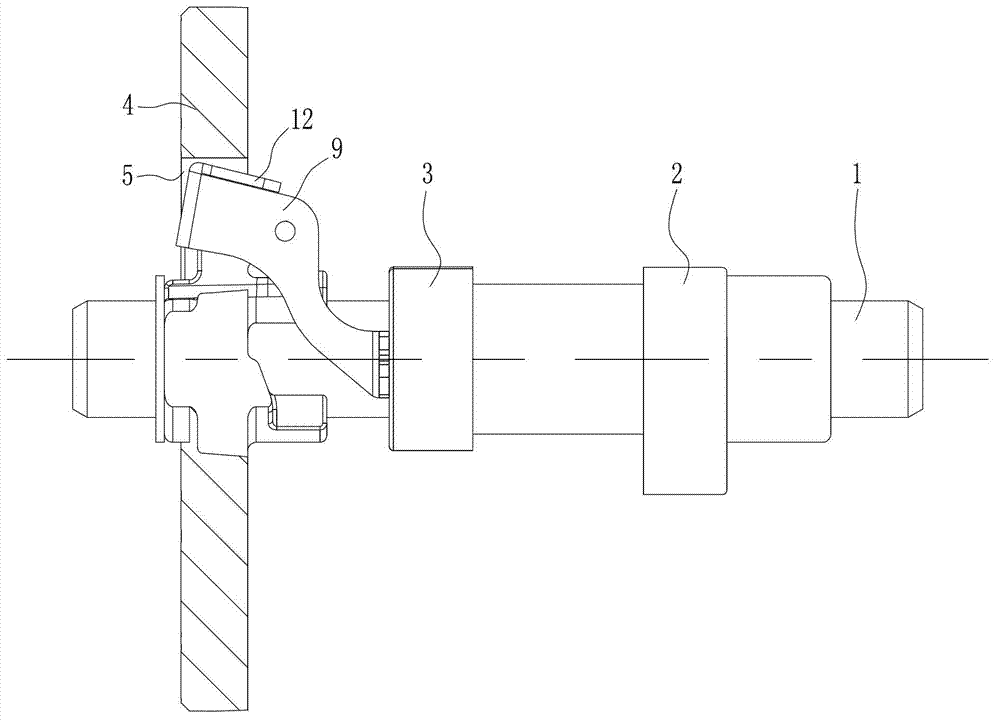

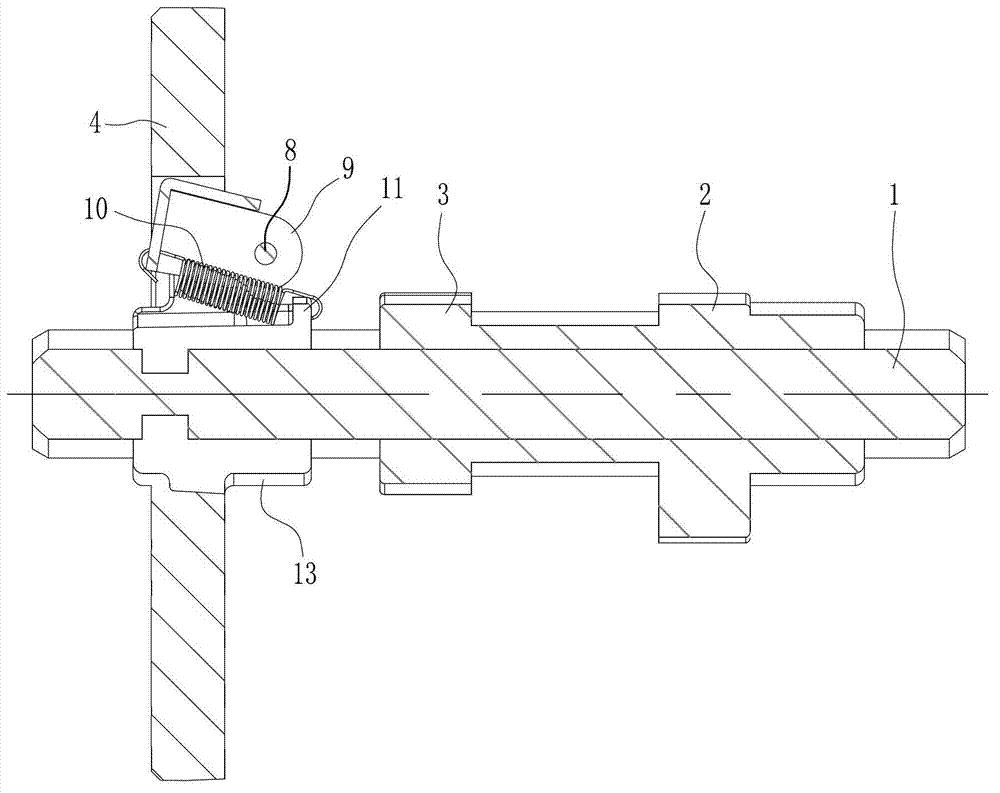

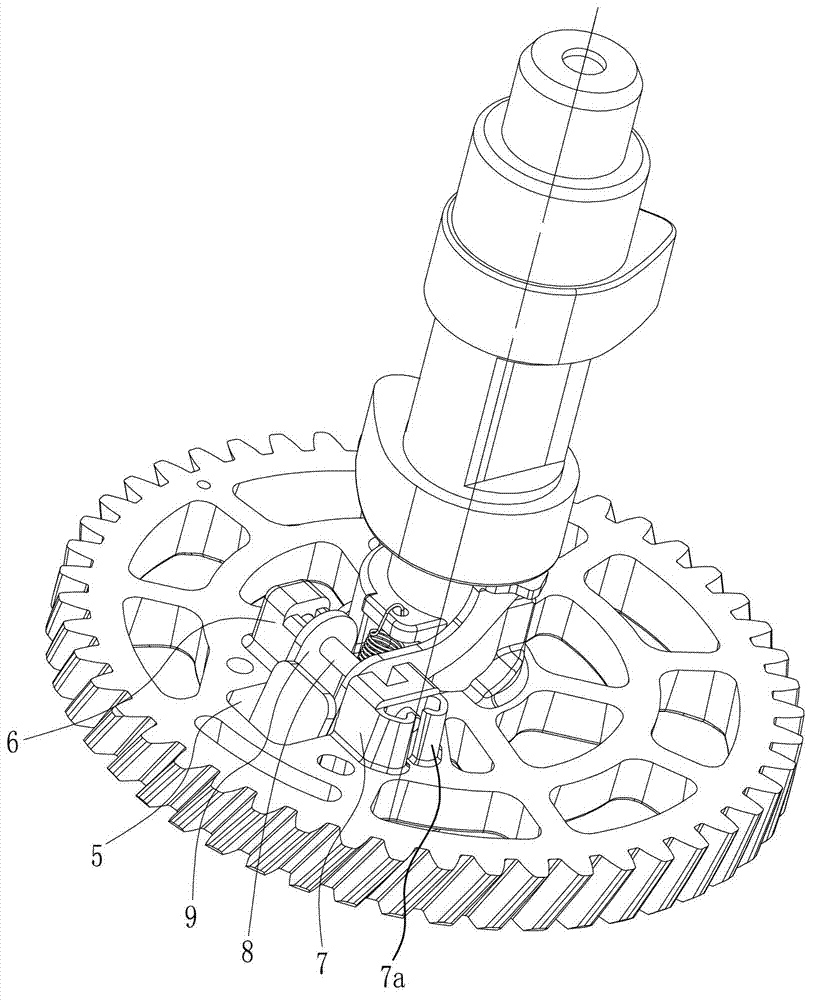

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the present invention consists of camshaft 1, intake cam 2, exhaust cam 3, drive gear 4, first pin seat 6, second pin seat 7, pin shaft 8, centrifugal flying block 9, reset extension spring 10, Hole seat 11, counterweight 12 and annular boss 13 etc. constitute. Wherein, the intake cam 2, the exhaust cam 3 and the drive gear 4 are all sleeved on the camshaft 1, and the installation method of each wheel is the same as that of the prior art, and will not be repeated here. The driving gear 4 is also called the timing gear, and the driving gear 4 is close to the shaft end of the camshaft 1, and the driving gear 4 and the intake cam 2 are separated on both sides of the exhaust cam 3. An annular boss 13 is arranged on the end face of the driving gear 4 facing the exhaust cam 3 , the annular boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com