Deodorant floor drain

A floor drain and anti-odor technology, applied to indoor sanitary pipeline installations, waterway systems, drainage structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

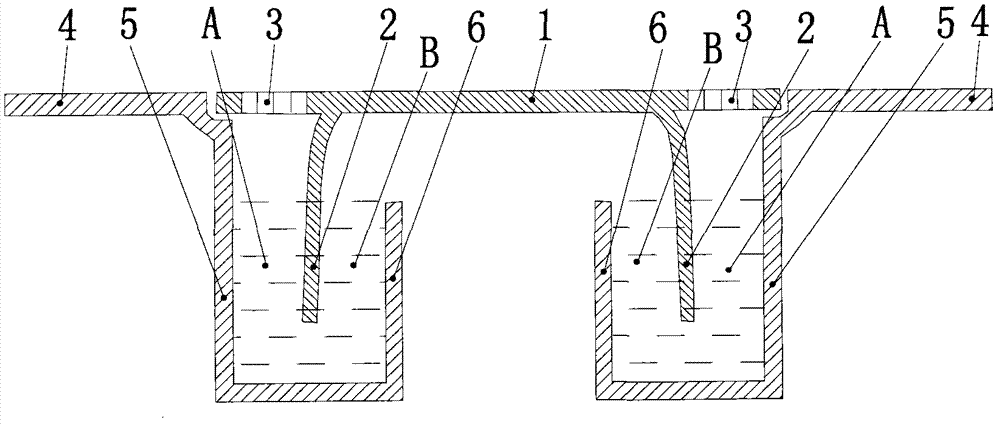

Image

Examples

Embodiment Construction

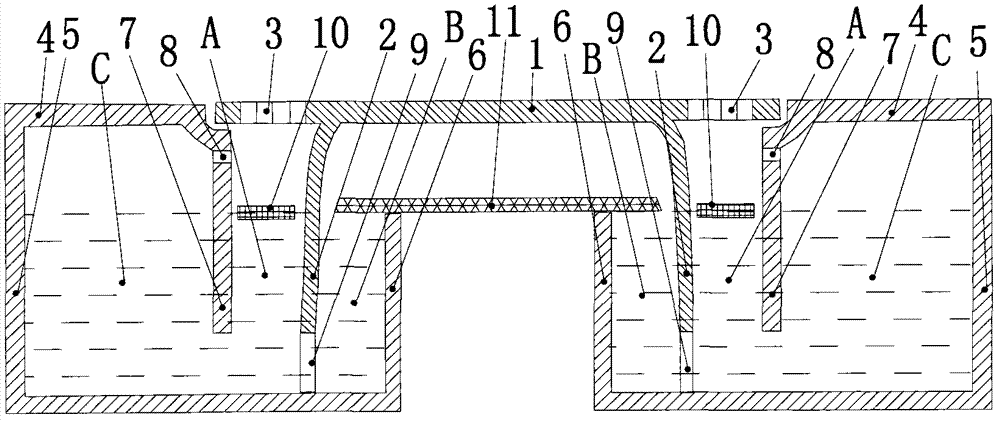

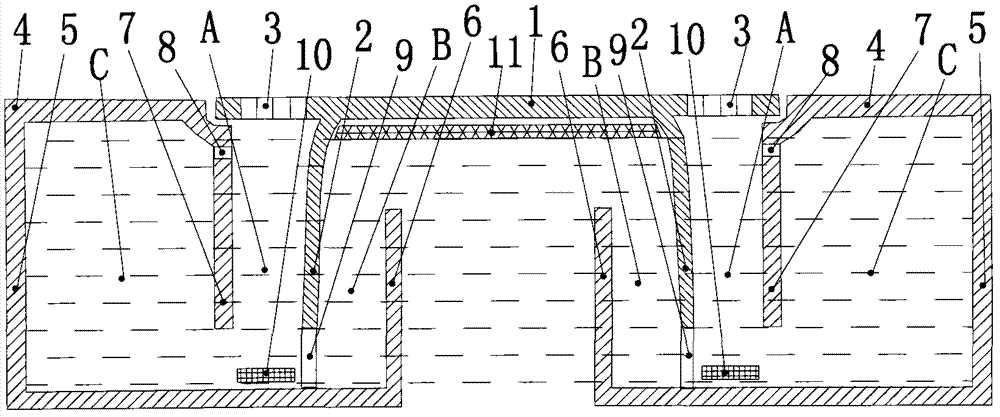

[0017] refer to figure 2 The deodorant floor drain of the present invention includes a floor drain cover 1, a floor drain seat 4, a water tank 3 and a water seal cover 2 on the floor drain cover 1, guide feet 9 at the lower end of the water seal cover 2, an inner shell 7 and an outer shell 5 on the floor drain seat 4 And the water seal pipe 6, the upper part of the inner shell 7 has a ventilation hole 8, the floor drain cover 1 is covered on the floor drain seat 4, there is a water chamber A between the inner shell 7 and the water seal cover 2, and the water seal cover 2 and the water seal tube There is a water chamber B between the 6, a water chamber C between the inner shell 7 and the outer shell 5, a floating plate 10 between the inner shell 7 and the water seal cover 2, and the water seal cover 2 on the top of the water seal tube 6 and the water There is an odor-proof board 11 between the sealed tubes 6;

[0018] Wherein, the lower end of the inner shell 7 is level with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com