Electric bilateral plow type unloader capable of adjusting unloading amount

A plow unloader and volume adjustment technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increased resistance, easy accumulation on the plowboard, and inability to adjust the unloading volume, so as to improve unloading efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

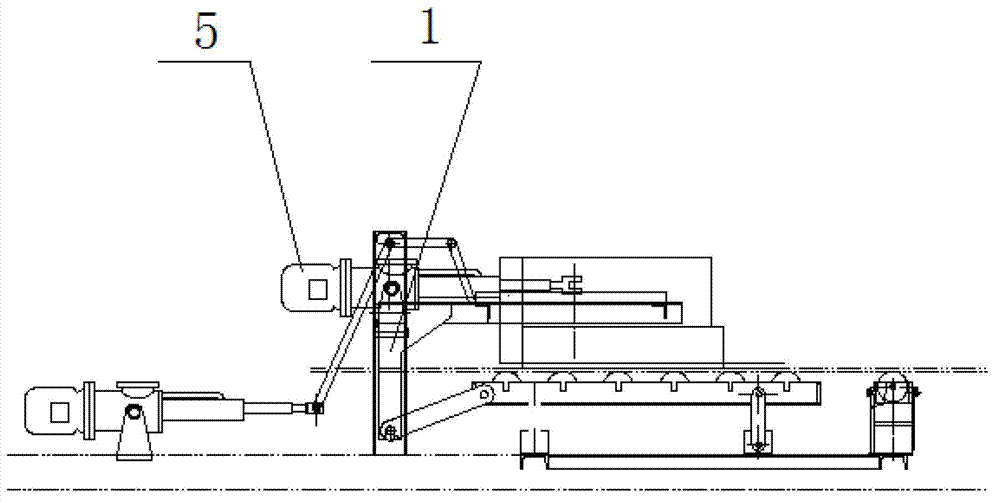

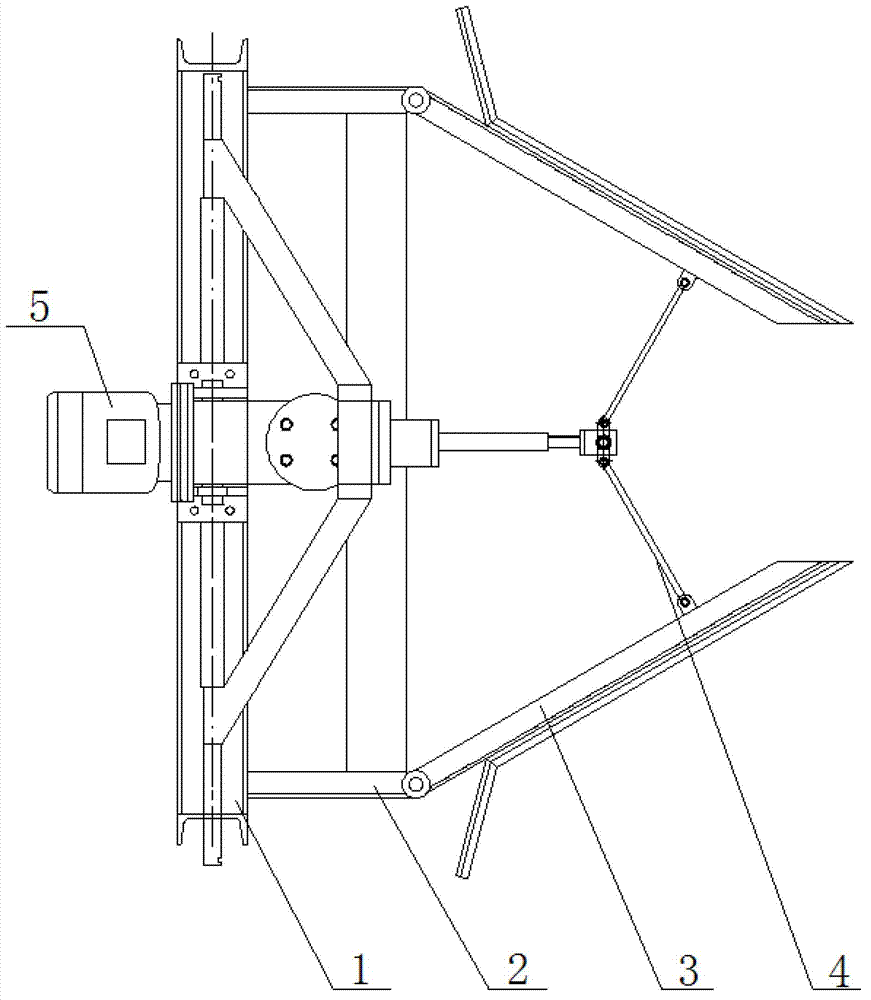

[0010] Such as figure 1 , figure 2 As shown, an electric adjustable double-sided plow unloader, including a frame 1, is characterized in that the coulter device is improved on the basis of the original plow unloader. The improved coulter device includes a coulter electric push rod 5, a coulter frame 2, a coulter 3, and a push rod 4; the tail end of the coulter electric push rod 5 is hinged at the middle part of the frame 1; The coulter frame 2 is hinged on the frame 1; the coulters 3 are symmetrically arranged, and one end is respectively connected to the coulter frame 2 through a door shaft, and the other end rotates freely around the door shaft; the ejector rod 4 is symmetrically arranged, and one end They are respectively hinged to the inner side of the coulter 3, and the other ends are respectively hinged to the front end of the electric push rod 5 of the coulter.

[0011] How to use and working principle

[0012] During the unloading work of the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com