Sectional travel characteristic pneumatic actuator device of turbocharger

A technology of turbocharger and pneumatic actuator, applied in machine/engine, combustion engine, internal combustion piston engine, etc., can solve the problems of linear control only, the cost increases a lot, and the stroke characteristics cannot be segmented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

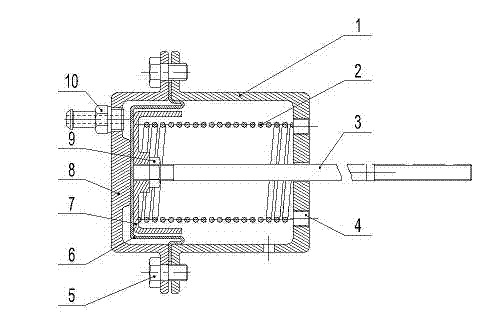

[0045] Example 1, such as image 3 , Figure 4 As shown, a pneumatic actuator device with segmented stroke characteristics of a turbocharger includes an upper casing 8 and a lower casing 1;

[0046] A rubber diaphragm 6 is provided between the upper case 8 and the lower case 1, and the upper case 8 and the lower case 1 are sealed and connected with the rubber diaphragm 6 through bolts 5;

[0047] The rubber diaphragm 6 separates the cavity between the upper casing 8 and the lower casing 1 into two cavities that are not connected to each other: a first cavity 26 and a second cavity 27 .

[0048] The upper casing 8 is provided with an air nozzle 10 communicating with the first cavity 26 .

[0049] A diaphragm seat 7 is provided at a position close to the rubber diaphragm 6 in the second cavity 27, and the main core rod 15 is connected to the diaphragm seat 7;

[0050] One end of the main core rod 15 is fixedly connected with the diaphragm seat 7 through a bolt 19 , and the ot...

Embodiment 2

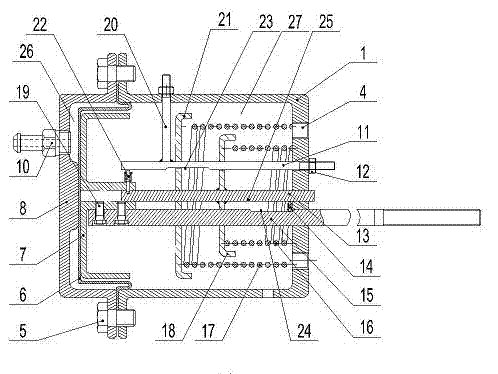

[0068] Example 2, such as Figure 5 As shown, in the above-mentioned embodiment 1, the diameters of the main spring 16 and the auxiliary spring 17 are the same, the main spring 16 is arranged between the main spring seat 18 and the lower housing 1, and the auxiliary spring 17 is arranged between the main spring seat 18 and the auxiliary spring seat Between 21.

[0069] When working, the gas with pressure enters the first cavity 26 formed by the upper casing 8 and the rubber diaphragm 6 from the gas nozzle 10, and pushes the rubber diaphragm 6 and the diaphragm seat 7 to move toward the lower casing 1, and the diaphragm The seat 7 moves together with the auxiliary core rod 13 through the upper locking pin assembly 22, the auxiliary core rod 13 compresses the main spring 16 through the welded main spring seat 18, and the main core rod 15 moves together with the diaphragm seat 7, Adjust the booster.

[0070] At this time, only the main spring 16 acts, and the travel characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com