Power assembly of range extended electric vehicle

A powertrain and electric vehicle technology, applied in the direction of electric vehicles, electric power units, power units, etc., can solve the problems of controller damage, increase of body beams, occupying the layout space of the whole vehicle, etc., to reduce vibration damage and save space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed instructions.

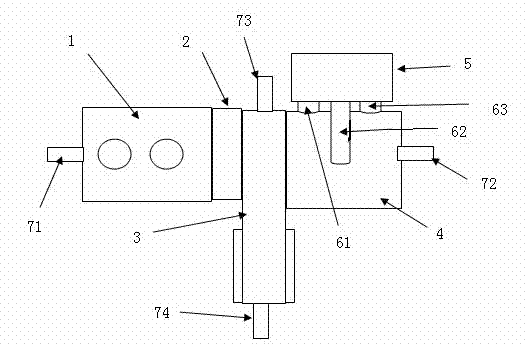

[0014] Such as figure 1 , the powertrain of the extended-range electric vehicle of the present invention includes an engine 1, a generator 2, a differential gear assembly 3, and a drive motor 4 arranged linearly in sequence, and the controller of the generator 2 and the drive motor 4 is integrated into an overall controller 5, and the overall controller 5 is fixed above the powertrain through damping shock absorbers 61, 62, 63. Powertrain mounts 71 , 72 , 73 and 74 are arranged at one end of the engine 1 , one end of the drive motor 4 and the upper and lower ends of the differential assembly 3 . The total controller 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com