Double-acting reciprocating booster pump

A booster pump and double-acting technology, which is applied in the field of reciprocating pumps, can solve the problems of uneven force, limited use range, waste of large horse-drawn carts, etc., and achieve the effect of increasing discharge flow and novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

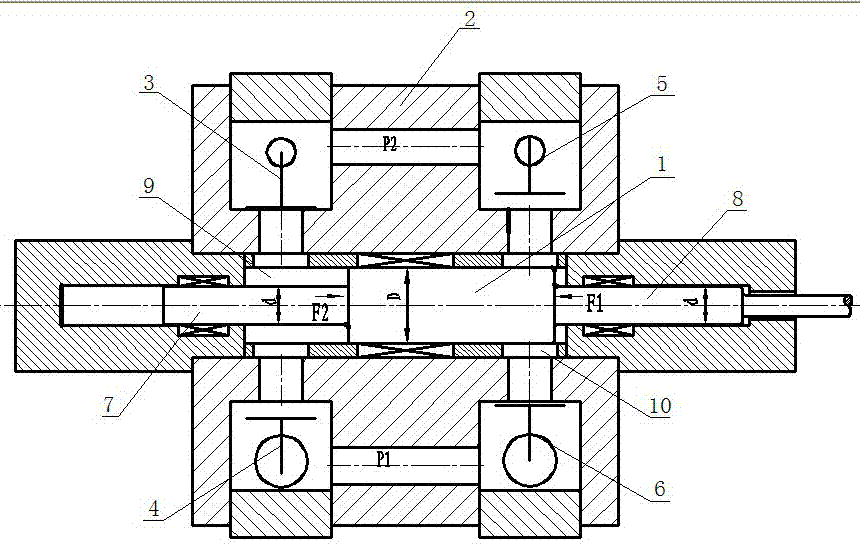

[0014] The double-acting reciprocating booster pump of the present invention is composed of a double-step plunger 1 and a pump body 2, and the pump body is integral, such as figure 1 As shown, the pump body 2 is provided with a left volume chamber 9 and a right volume chamber 10, a suction valve assembly I4 and a discharge valve assembly I3 are installed in the left volume chamber 9, and a suction valve assembly II6 is installed in the right volume chamber 10 and discharge valve assembly II5; a double-step plunger 1 and its sealing assembly are installed between the left volume chamber 9 and the right volume chamber 10, and the double-step plunger 1 and its sealing assembly separate the left volume chamber 9 and the right volume chamber 10 . And at the two ends of the main plunger of the double-step plunger 1, there is an auxiliary plunger I7 and an auxiliary plunger II8 with the same diameter and their sealing components. The diameters of the auxiliary plunger I7 and the auxi...

Embodiment 2

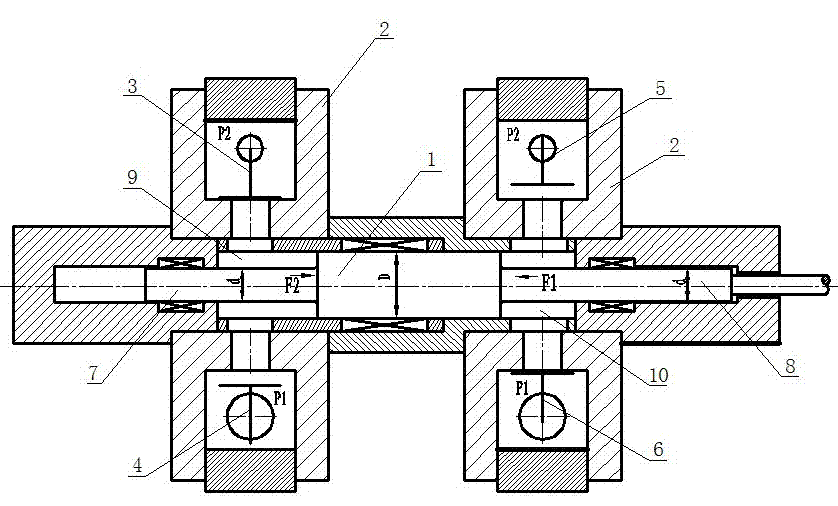

[0016] In the double-acting reciprocating booster pump of the present invention, the pump body is split, such as figure 2 Shown, others are with embodiment 1. The double-step plunger seal assembly of the present invention may also adopt a stepped piston seal assembly structure.

[0017] The specific working process is as follows:

[0018] When the double-stepped plunger 1 moves to the right, the suction valve 4 of the volume chamber 9 at the left end is opened, the discharge valve 3 is closed, and the volume chamber 9 at the left end completes the suction process. At this time, the suction valve 6 of the volume chamber 10 at the right end is closed, and the discharge valve 5 is opened. , the right end volume chamber 10 completes the discharge process. A rated flow is discharged during this process. At the same time, the plunger is subjected to a leftward force F1=π(D 2 -d 2 )(P2-P1) / 4;

[0019] When the double-step plunger 1 moves to the left, the discharge valve 5 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com