Device and method for removing high-concentration sulfur dioxide through interactive spray washing

A sulfur dioxide, high-concentration technology, applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of pH value change rate, temperature change is very different, absorption operation is difficult to control, slurry pH, slurry temperature is difficult to control, etc. problem, to achieve the effect of ensuring constant and consistent, stable absorption operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

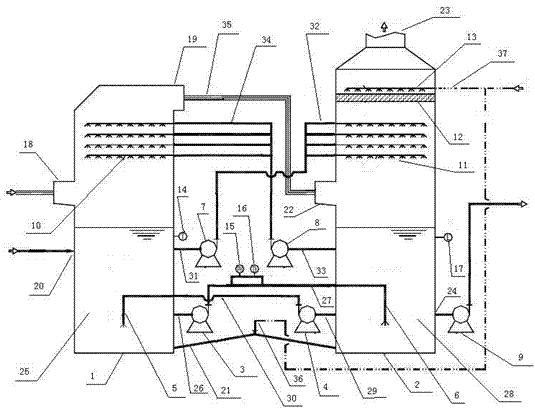

[0034] like figure 1 As shown, the device for removing high-concentration sulfur dioxide by alternating spraying and washing includes an absorption tower A 1 with a flue gas inlet A 18 in the middle and lower part, a flue gas outlet A 19 in the upper part, and an absorbent inlet 20 in the lower part. The bottom connecting pipe 21 communicates with the absorption tower A1, and the middle and lower part is provided with a flue gas inlet B 22, the top is equipped with a flue gas outlet B 23, and the bottom is equipped with a slurry discharge port 24 Absorption tower B2; the flue gas outlet A 19 Communicate with the flue gas inlet B 22 through the flue gas pipe 35;

[0035] The upper part of the absorption tower A1 is provided with a spray layer A10 with nozzles, and the lower part is a slurry pool A25; The demister rinsing water pipe network 13 with nozzles, the demister 12 and the spray layer B 11 with nozzles, the lower part of the absorption tower B 2 is the slurry pool B 28;...

Embodiment 2

[0043] The method for removing high-concentration sulfur dioxide by alternating spraying and washing: When using the method of the present invention to wash and remove high-concentration sulfur dioxide flue gas, pass the flue gas containing high-concentration sulfur dioxide into the absorption tower A1, and start the slurry circulation pump B8 to extract and absorb The slurry in the slurry tank B 28 at the bottom of the tower B 2 is sent to each spray layer A 10 in the absorption tower A 1, the slurry is atomized by the nozzles connected to each spray layer A 10 and sprayed evenly downwards, and the slurry is dispersed into The fine liquid droplets cover the section corresponding to the absorption tower A 1, contact with the flue gas flowing upwards countercurrently, absorb the sulfur dioxide in the flue gas and fall into the slurry pool A 25 at the bottom of the absorption tower A 1; the flue gas is absorbed for the first time After washing, it enters the absorption tower B2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com