Gridding reaction inclined tube settling pond

A technology of inclined tube sedimentation tank and reaction tank, applied in the direction of sedimentation tank, feeding/discharging device of sedimentation tank, etc., can solve the problems of insufficient flocculation speed, unguaranteed effect, sludge accumulation, etc., and improve water production. , The effect of flocculation reaction is good and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

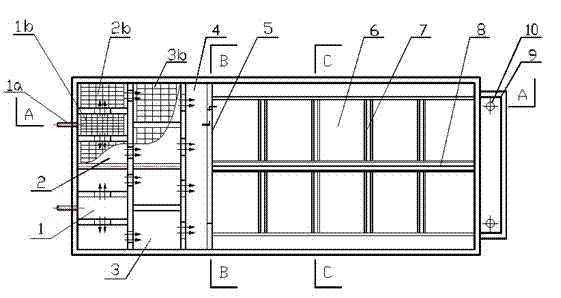

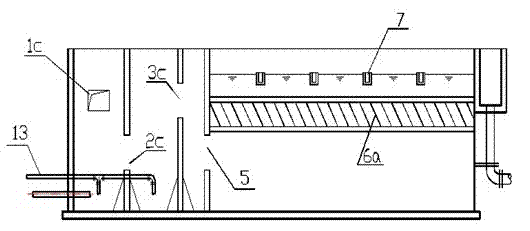

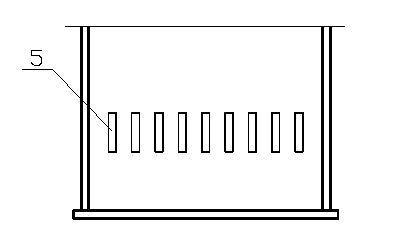

[0022] Such as Figure 1 to Figure 6 As shown, the grid reaction inclined tube sedimentation tank includes the grid reaction tank and the inclined tube sedimentation tank 6 communicated with the grid reaction tank through the water distribution corridor 4; the grid reaction tank is composed of the first level vertical shaft and the It consists of the second-level shaft connected by the first-level shaft, and the first-level shaft is further divided into the first grid shaft 1 and the left and right sides of the first grid shaft 1 and passing through the upper left and right sides of the first grid shaft 1 wall. The second vertical shaft 2, which is connected to the first vertical shaft 1 by the water outlet hole 1c, is provided with a static mixer and a water inlet pipe 1a at the bottom of the first vertical shaft 1; Corresponding to and formed by the third shaft 3 connected to the second shaft 2 through the water outlet hole B 2c arranged at the lower part of the second shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com