Manufacture methods of keyboard and key cap

A manufacturing method and keycap technology, applied to electrical components, electric switches, circuits, etc., can solve the problems of complex manufacturing process, low practicability, unfavorable mass production, etc., and achieve the effect of simple manufacturing process and good reflective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are given in conjunction with the embodiments.

[0028] see figure 1 , figure 1 It is a schematic diagram of a keyboard 1 according to an embodiment of the present invention. like figure 1 As shown, the keyboard 1 includes a bottom plate 10 and a plurality of key modules 12 . The key module 12 is disposed on the bottom plate 10 for the user to press, so as to execute the function that the user wants to input.

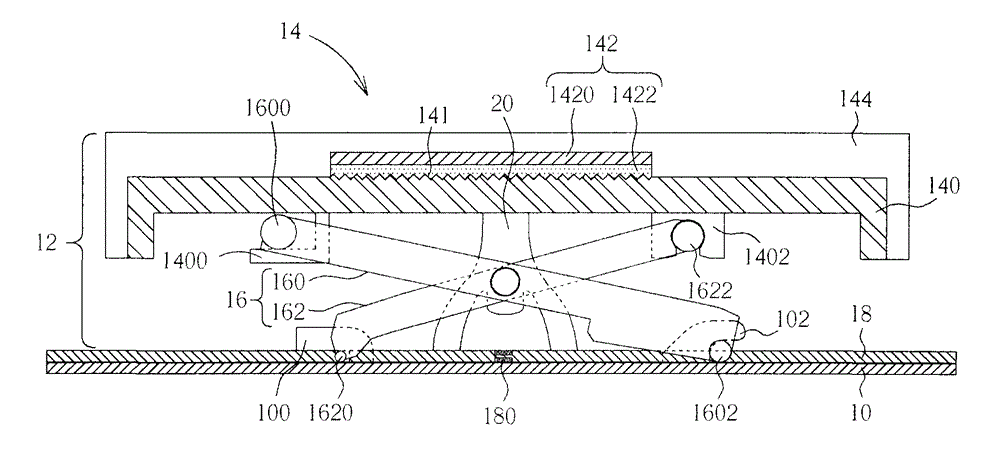

[0029] see figure 2 , figure 2 for figure 1 A cross-sectional view of one of the key modules 12 along the X-X line. like figure 2 As shown, the key module 12 includes a key cap 14 , a lifting support device 16 , a circuit board 18 and an elastic member 20 . The keycap 14 includes a keycap body 140 , a metal pattern layer 142 and a protective layer 144 . The lifting support device 16 and the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com