Full coated disk-shaped porcelain (glass) composite shed insulator for power transmission line

A transmission line, full-covering technology, applied in the direction of circuits, insulators, suspension/strain insulators, etc., can solve the problems of short service life, etc., and achieve the effect of improving withstand voltage level, increasing dry area, and good water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

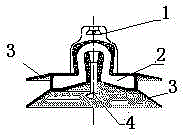

[0016] A fully-covered disc-shaped porcelain (glass) composite umbrella skirt insulator for power transmission lines, which is composed of a steel cap, a porcelain core frame, a silicon rubber composite umbrella skirt, and steel feet; the porcelain core frame is fully covered in the silicone rubber composite umbrella In the skirt, the steel cap rubber is installed on the silicone rubber composite umbrella skirt at the upper part of the porcelain core skeleton, and the steel foot rubber is installed on the silicone rubber composite umbrella skirt at the lower part of the porcelain core skeleton. The silicone rubber composite umbrella skirt and porcelain core skeleton are molded by injection. The composite umbrella skirt is made of high-quality silicone rubber compound and vulcanized in a mold under high temperature and high pressure; the middle ceramic core is a product with rich operating experience and reliable product quality. The composite umbrella skirt is tightly bonded to...

Embodiment 2

[0018] A full-coated disc-shaped porcelain (glass) composite umbrella skirt insulator for power transmission lines, which is composed of a steel cap, a glass core frame, a silicone rubber composite umbrella skirt, and steel feet; the glass core frame is fully covered with the silicone rubber composite umbrella In the skirt, the steel cap glue is installed on the silicone rubber composite umbrella skirt at the upper part of the glass core frame, and the steel foot glue is installed on the silicone rubber composite umbrella skirt at the lower part of the glass core frame. The silicone rubber composite umbrella skirt and glass core skeleton are molded by injection. The composite umbrella skirt is made of high-quality silicone rubber compound and vulcanized in a mold under high temperature and high pressure; the middle glass core is a product with rich operating experience and reliable product quality. The composite umbrella skirt is tightly bonded to the glass core, which effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com