Free end spinning machine piecing trolley

A technology of spinning machine and free end, which is applied in the field of piecing trolley of free-end spinning machine, which can solve the problems of large amount of labor and the limitation of rotor speed, so as to improve the efficiency of piecing, reduce the workload of manpower, improve the success rate of piecing and The effect of joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

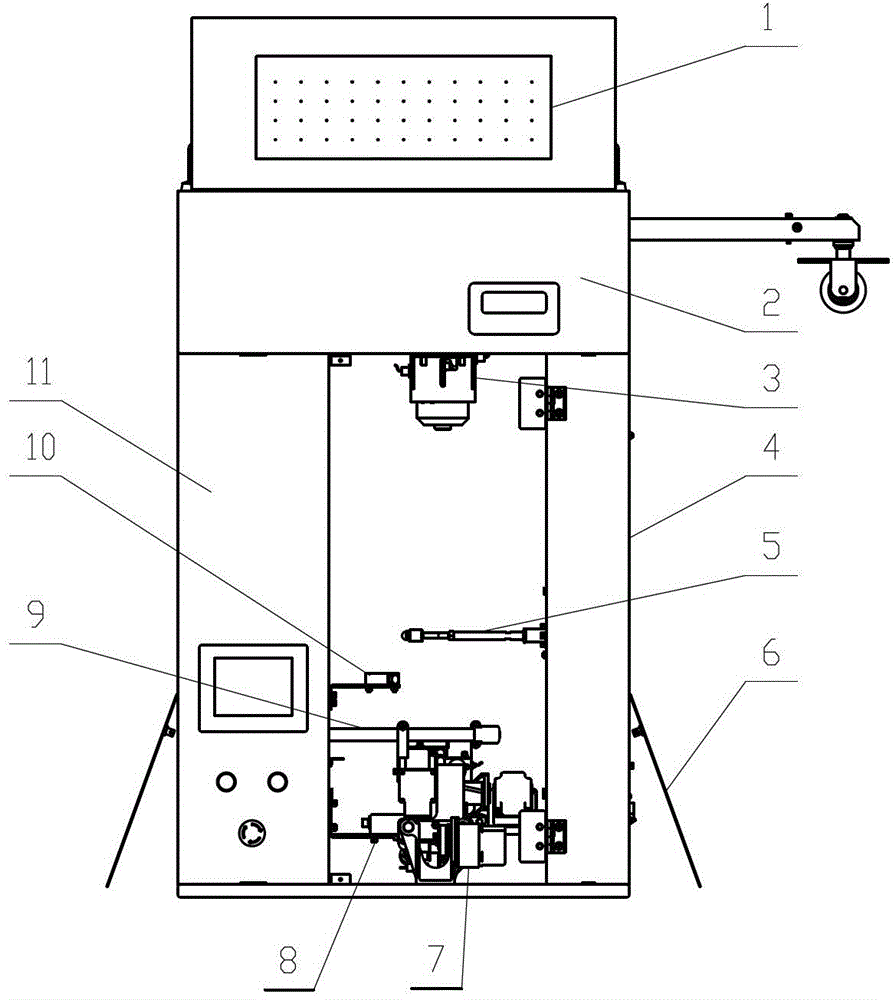

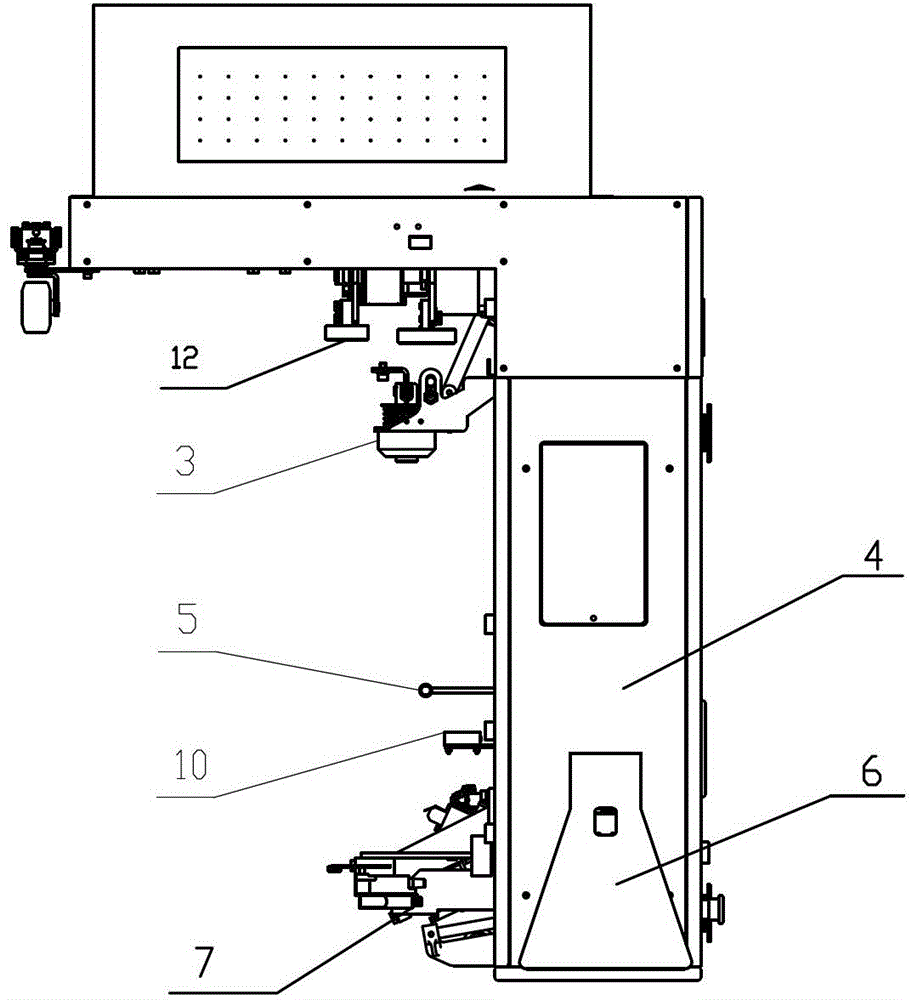

[0013] like Figure 1~2 As shown, the present invention includes a frame 4, a driving device, a positioning device 3, an automatic splicing device 7, a rotor speed measuring device 8, a lifting device 5, a yarn storage device 9, a communication device 10, an electric control system 2, and a blowing and sucking device 11 and the human body induction device 6, the frame 4 includes a horizontal part and a vertical part; the driving device is installed on the frame horizontal part, including a power mechanism 1 and a moving mechanism 12 connected by transmission, the moving mechanism 12 is mainly composed of rollers, and the moving mechanism 12 Press against the traveling track of the trolley on the main machine of the spinning machine, mount the jointing trolley on the traveling track of the trolley, and drive the jointing trolley to tour through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com