Water gel and method for manufacturing the same, as well as water retaining gel mat and method for manufacturing the same

A technology of water-retaining gel and manufacturing method, which is applied to mattresses, absorbent pads, spring mattresses, etc., can solve problems such as poor water-retaining performance, and achieve the effects of high elasticity and increased production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

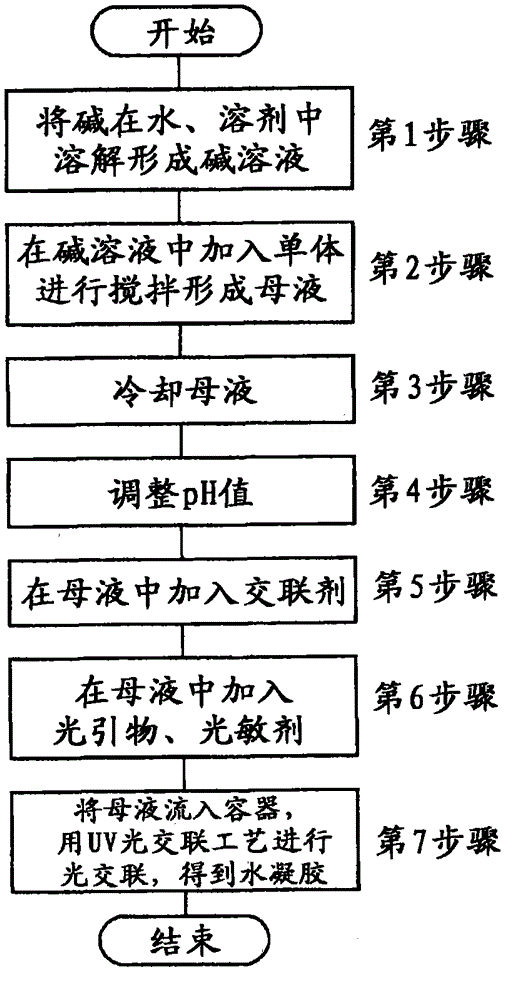

[0040] The hydrogel 1 according to Example 1 of the present invention and its production method will be described. The hydrogel 1 involved in the present embodiment 1, via figure 2 Manufactured by the manufacturing steps shown.

[0041] (step 1)

[0042] A base such as sodium hydroxide is dissolved in water or a solvent, and stirred to completely dissolve to form an alkaline solution, which is then cooled.

[0043] (step 2)

[0044] When the temperature of the alkaline solution is lowered to around 25°C, monomers such as acrylic acid, acrylate, and acrylamide are added to the alkaline solution, and stirred and mixed until the solution becomes clear and transparent. Hereinafter, the solution obtained here is simply referred to as "mother liquor". The monomer content in the mother liquor is about 10%-20%.

[0045] (step 3)

[0046] Cool the mother liquor obtained in the second step to below 25°C.

[0047] (step 4)

[0048] The pH of the above-mentioned mother liquor is me...

Embodiment 2

[0079] Hereinafter, the water-retaining gel pad 10 according to Example 2 of the present invention and its manufacturing method will be described.

[0080] The water-retaining gel pad 10 and the water-retaining gel 21 involved in the present embodiment 2, via Figure 4 Manufactured by the manufacturing steps shown.

[0081] (step 1)

[0082] Sodium hydroxide is dissolved in water and a solvent, stirred to completely dissolve, and then cooled. The consumption of water is 10%-30% of the total mass of the reaction system, and the consumption of sodium hydroxide is 5%-20% of the total mass of the reaction system.

[0083] (step 2)

[0084] When the temperature of the sodium hydroxide solution drops to around 25°C, add glycerin, ethyl cellulose, and polyacrylamide as water retention factors into the alkaline solution, and stir and mix until the solution becomes clear and transparent.

[0085] The amount of glycerol is 10% to 30% of the total mass of the reaction system, the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com