Multi-layer helix rope winding groove coiling barrel

A spiral rope and reel technology, which is applied in the field of construction machinery piling machinery and equipment, can solve the problems of wire rope disorder, wear and tear, and short life of the wire rope, and achieve the effects of avoiding disorder, meeting the needs of use, and simple manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

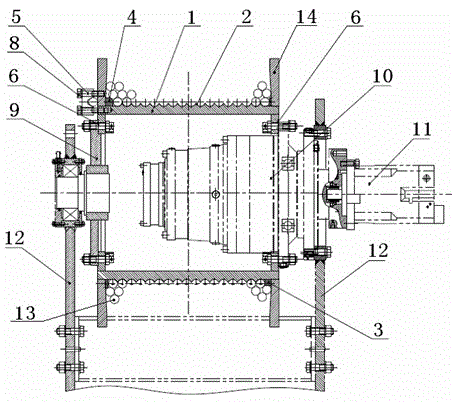

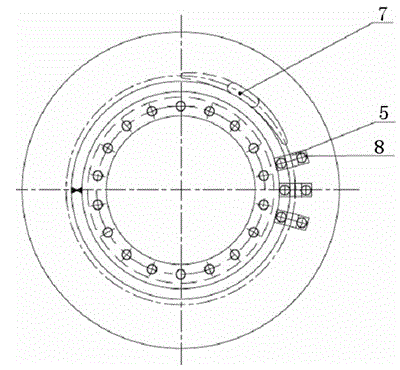

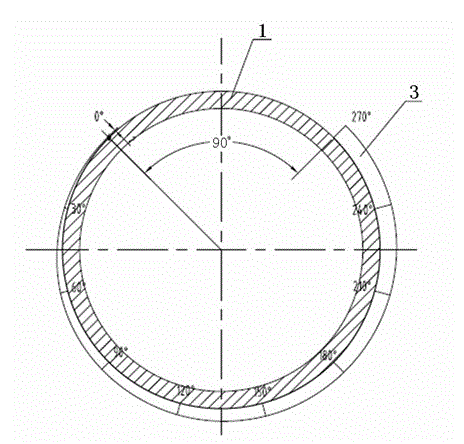

[0025] see Figure 1-Figure 6 , a multi-layer winding spiral rope groove reel, including a reel 1, a spiral rope groove 2, a steel wire rope 13, and a reel side plate 14, the two ends of the reel 1 are installation interfaces 6, on the reel side plate 14 Open the rope hole 7 along the winding direction of the steel wire rope 13, the end of the spiral rope groove 2 is provided with a climbing rope block 3, the initial end of the steel wire rope 13 is provided with a wedge-shaped block 4, and the wrapping of the climbing rope block 3 on the reel 1 horn from 0 to 270 , the wrap angle of The height of the inner climbing rope block 3 changes from 0 When the 2 mm gradually increases that smooth transition to 270 is equal to the diameter of the wire rope 13, from 0 The height of the climbing rope block 3 is designed to be 2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com