Sealing structure for sludge collecting cylinder and central post of sludge scraping suction dredger

A technology of sealing structure and center column, which is applied in the direction of the feeding/discharging device of the settling tank, settling tank, etc., can solve the problems of poor dynamic sealing effect and easy wear of the sealing structure, so as to prevent leakage, not easy to wear, reduce The effect of consumption of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

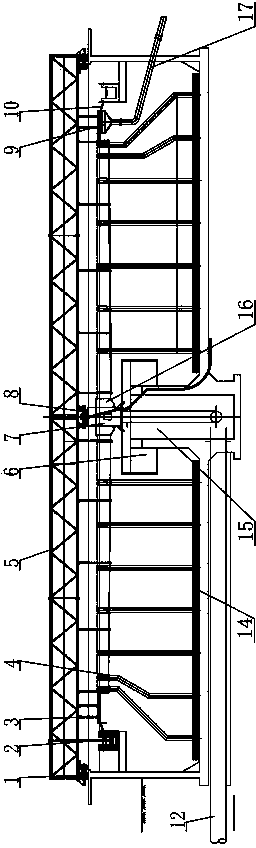

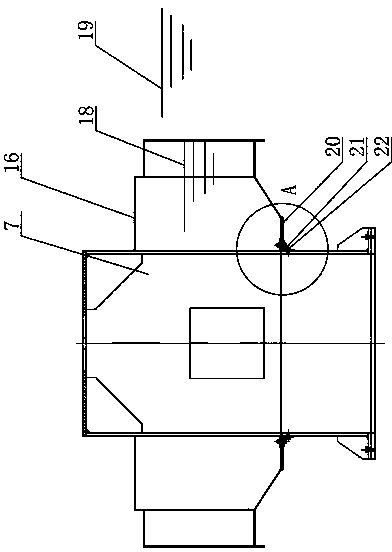

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0021] like image 3 , Figure 4 As shown, the present invention uses fasteners 22 to fix a flange 21 with a ring-shaped right-angle section at the middle of the outer peripheral surface of the central column 7, and then uses fasteners to fix the upper and lower layers of rubber rings 20 on the horizontal plane of the flange 21 , The aperture value of the bottom wall of the mud collecting cylinder 16 is greater than the outer diameter value of the central column 7 and smaller than the outer diameter value of the rubber ring 20 at the same time. The bottom wall of the mud collection cylinder 16 is directly placed on the upper surface of the upper rubber ring 20 . The rubber ring 20 is made of higher density and wear-resistant nitrile rubber, and every circle of rubber ring 20 is made up of two semicircular rings, such as Figure 5 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com