Supercritical water reactor combined square fuel assembly and core using the same

A supercritical water reactor and fuel assembly technology, applied in the assembly of fuel elements, moderator/core structure, reactor, etc., can solve the problem of high fuel pellet and fuel rod cladding temperature, flow resistance and core pressure Reduce the size of the core, unfavorable core performance and safety, etc., to achieve the effect of reducing structural materials, improving safety, and good engineering realizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment, a kind of supercritical water reactor combined square fuel assembly, reactor core and moderator coolant dual flow flow method that the present invention proposes, carry out further introduction:

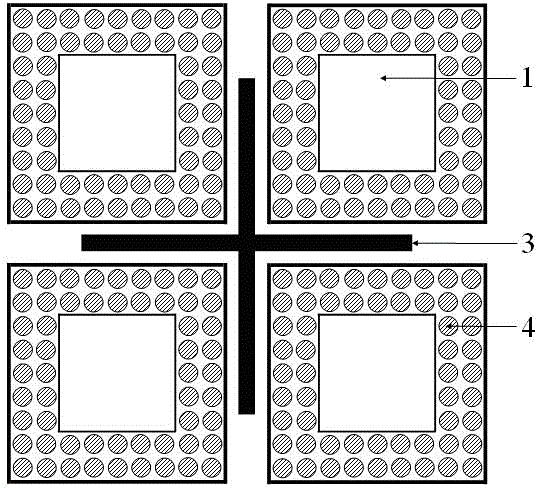

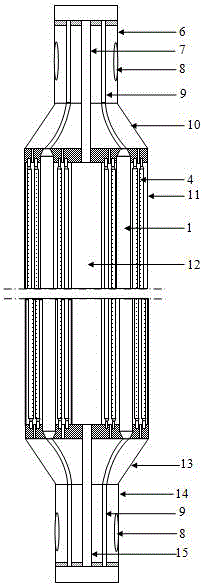

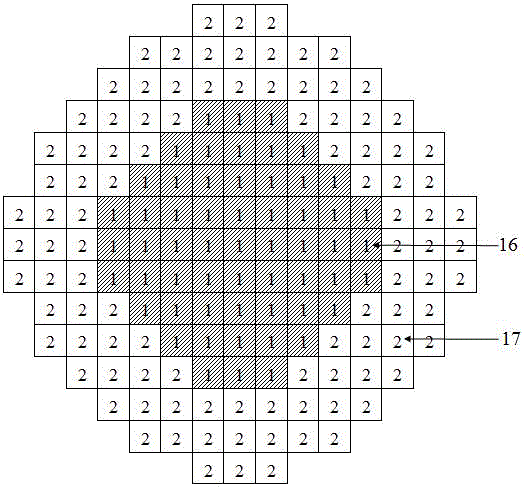

[0033] like figure 2 The supercritical water reactor combined square fuel assembly shown is composed of a subassembly 11, an upper pipe seat 10, a lower pipe seat 13, an upper head 6, and a lower head 14. The upper end of the subassembly 11 is equipped with the upper pipe seat 10, and the upper pipe The upper end of the seat 10 is equipped with an upper head 6, the lower end of the subassembly 11 is installed with a lower pipe seat 13, and the lower end of the lower pipe seat 13 is installed with a lower head 14, and the upper and lower ends are provided with side holes 8; figure 1As shown, the fuel assembly is composed of four identical subassemblies 11 arranged in a square of 2×2, a cross-shaped area 12 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com