Biomass drying and heating system

A heating system and biomass technology, applied in the field of biomass drying and heating systems, can solve problems such as power waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

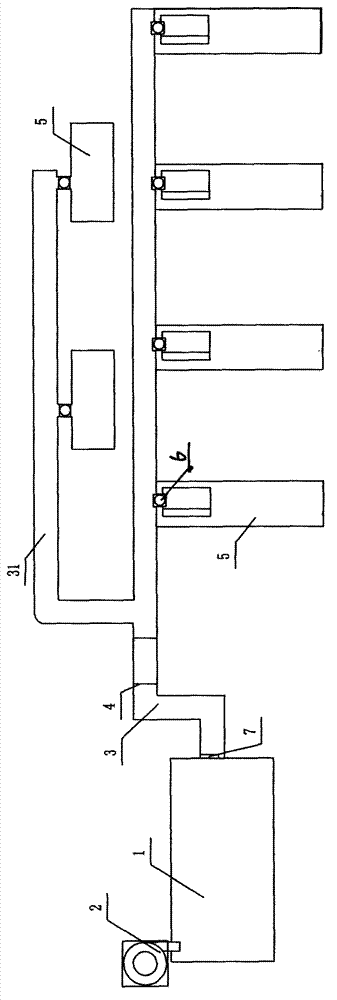

[0015] Such as figure 1 As shown, a kind of biomass drying and heating system of the present embodiment includes a biomass hot blast stove 1, a blower 2 is connected to the air inlet end of the biomass hot blast stove 1, and a heat preservation pipe 3 is connected to the air outlet end, and a heat preservation pipe 3 is connected to the heat preservation pipe 3 A hot air induced draft fan 4 is also arranged near the front end in the interior; at least one oven 5 is connected to the heat preservation pipe 3 .

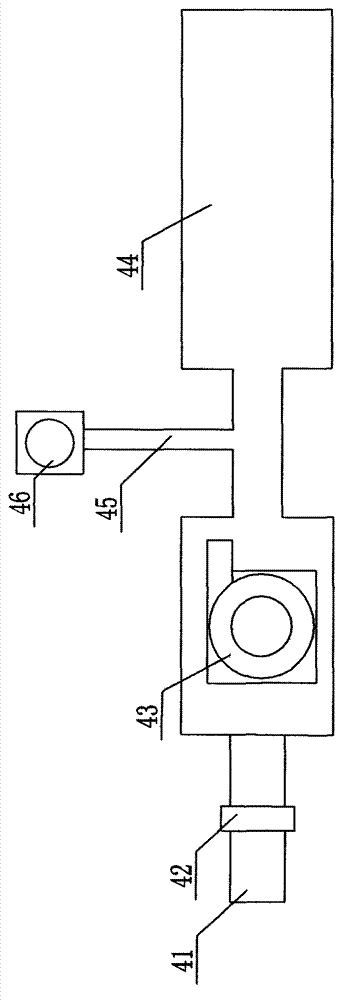

[0016] Look figure 2 , the hot air induced fan 4 includes an air inlet pipe 41, on which an air valve 42, an induced fan 43 and a drying tunnel 44 are sequentially installed, and the air valve 42 can control the size of the wind. A branch pipe 45 is arranged between the drying tunnel 44 and the induced draft fan 43, and a cooling fan 46 is arranged on the branch pipe 45, and the temperature of the hot air drawn in by the induced draft fan 43 is adjusted by the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com