Semi-automatic 90° openable frame

An open and frame technology, applied in building components, buildings, ceilings, etc., can solve the problems of easy aging of the ceiling, low fire resistance, etc., and achieve the effect of realizing application value, convenient installation, and good positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

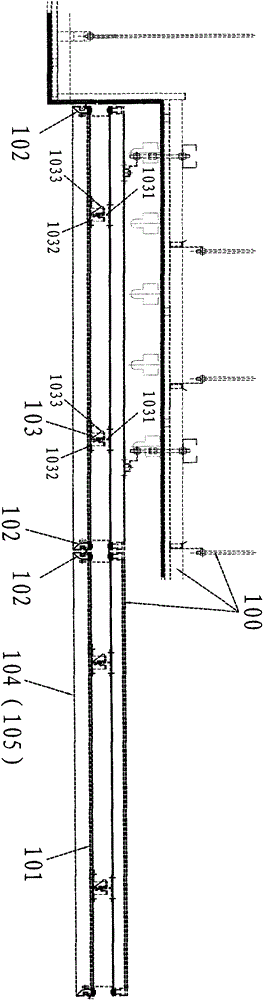

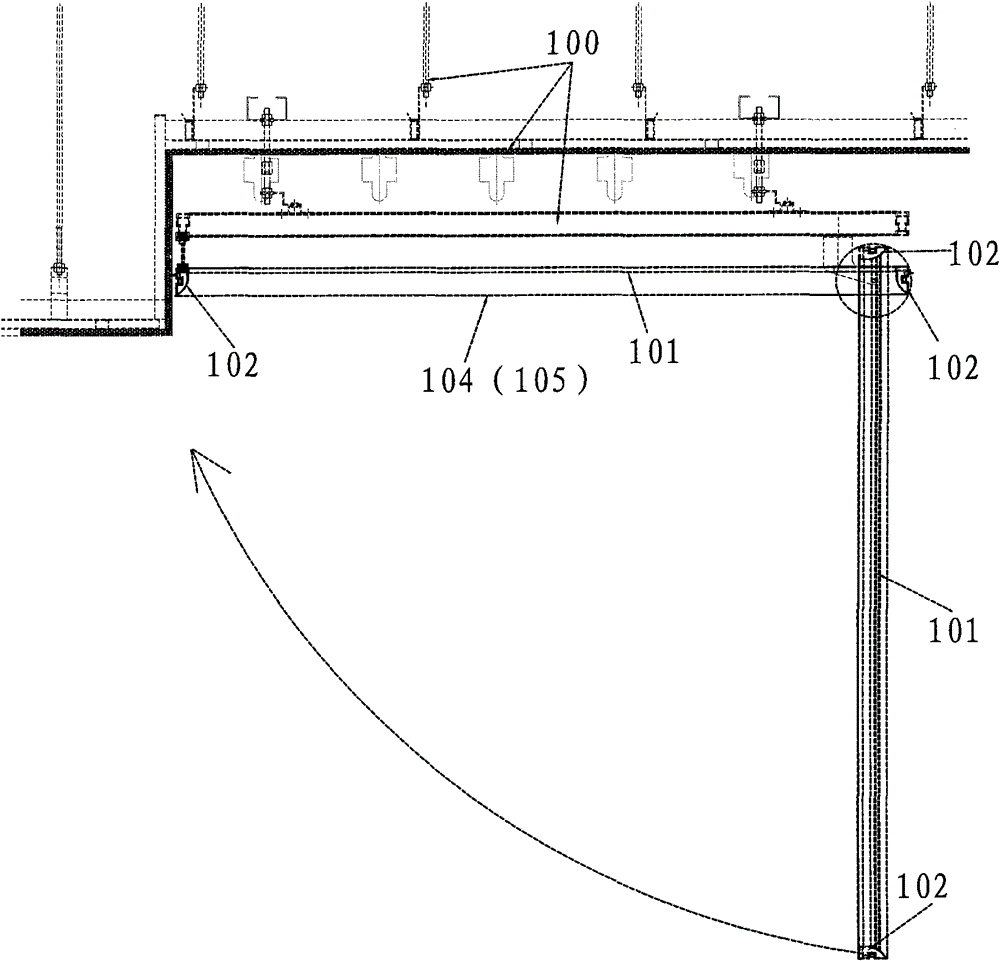

[0017] see figure 1 , 2 As shown, an open frame provided in this embodiment mainly includes: a top floor fixing bracket 101 fixed below the ceiling frame 100 on the top of the roof, the top floor fixing bracket 101 is a keel bracket, mainly composed of multiple keel segments connected, The keel sections are connected by two G-shaped movable parts 102 facing the G-shaped openings, the keel section at the end is connected with the ceiling frame 100 through a G-shaped movable part 102, and each G-shaped movable part 102 passes through a rotating shaft Connected with the ceiling frame 100, each rotating shaft is arranged on the G-shaped closed end of the corresponding G-shaped movable part 102, and each keel osteotomy segment can rotate 90 degrees downward along the G-shaped movable part 102 at its end. A locking device 103 is arranged between each keel section and the ceiling frame 100 above it. When each keel section of the top floor fixing bracket 101 is horizontal and each lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com