Apparatus and method for detecting loosening of carrying dolly chain lifting chain

A technology for handling trolleys and detection devices, which is applied in the field of detection devices for lifting chains of transporting trolleys, which can solve problems such as equipment failures, hidden dangers of safety accidents, and falling off, and achieve the effects of ensuring stability, reducing labor intensity, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

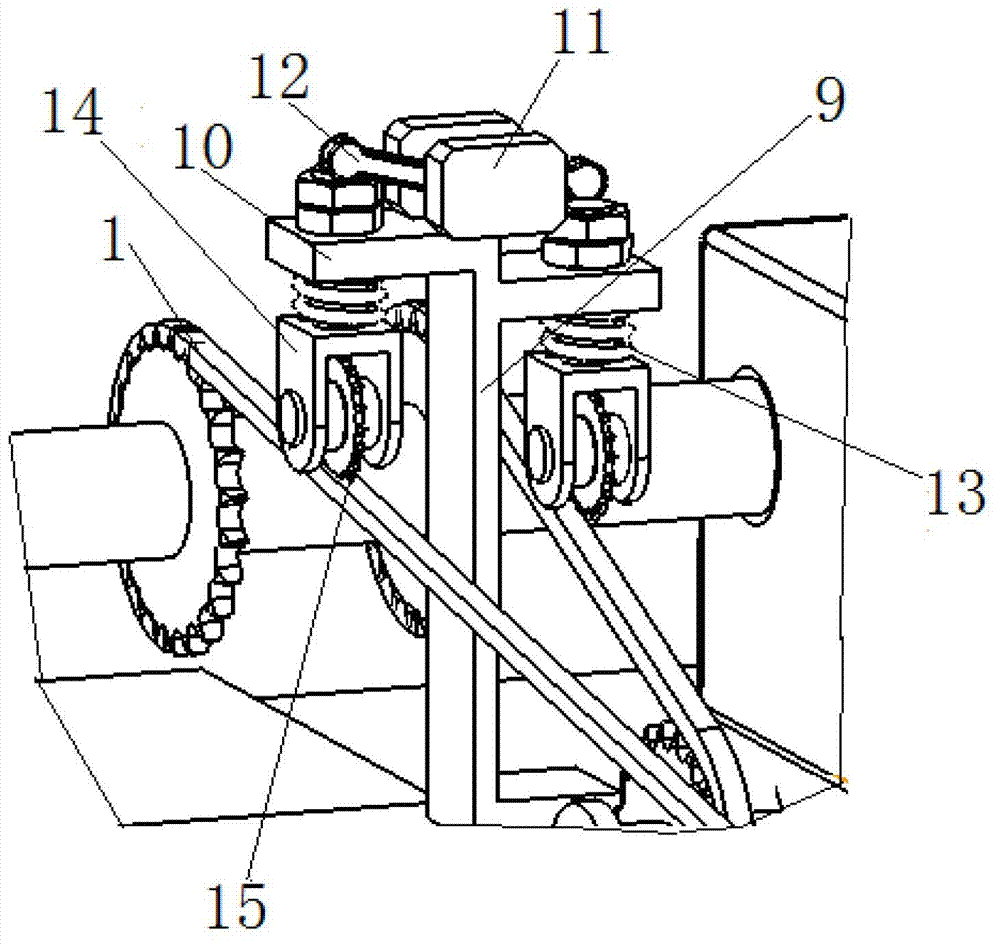

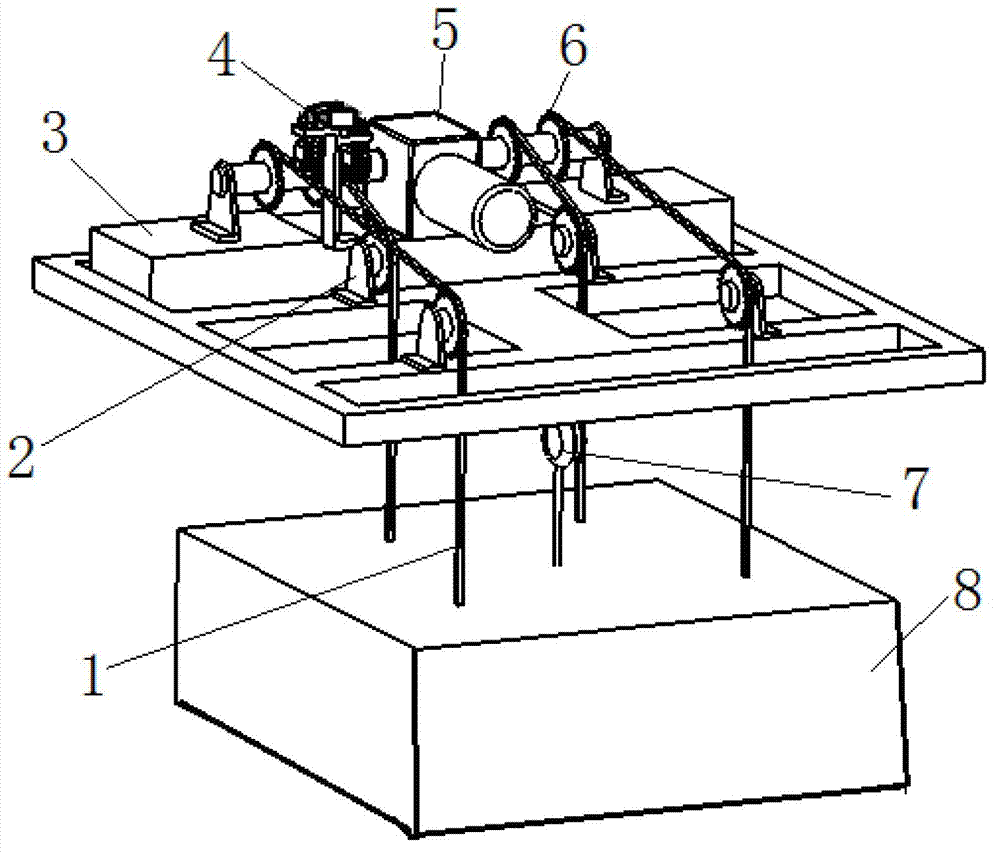

[0025] like figure 1 As shown, the lifting chain detection device for the transport trolley includes a support 9 installed on the frame between the drive sprocket and the transition sprocket, the top of the support 9 is a base 10; There is a limit switch 11 that provides the action signal to the PLC system that controls the operation of the entire equipment. The limit switch 11 detects whether the lifting chain 1 is slack and feeds back the action signal to the PLC system; The tension wheel 15, the tension wheel 15 can detect the tension of the lifting chain 1, the tension wheel 15 is arranged below the base 10 through the tension wheel bracket 14; one end of the tension wheel bracket 14 is connected with the tension wheel 15 , the tensioning wheel 15 is connected with the tensioning whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com