SNCR (Selective Non Catalytic Reduction) denitration automatic anti-blocking spray atomization spray gun device for smoke environment

A fume environment, spray atomization technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of affecting the mixing effect of reducing agent and flue gas, affecting long-term stable operation, clogging and hardening, etc. , to achieve the effect of being suitable for popularization and use, easy maintenance and repair, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

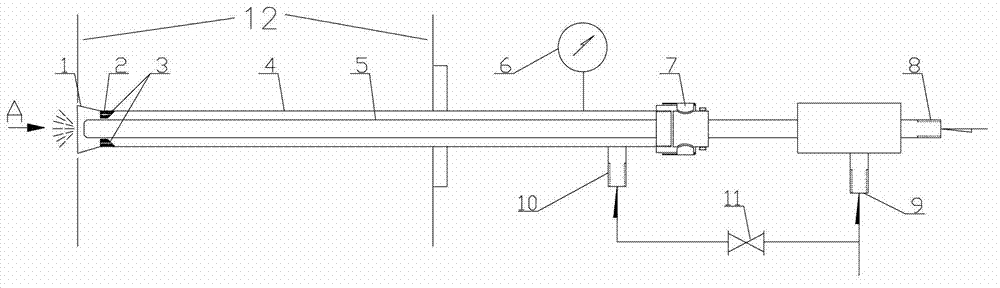

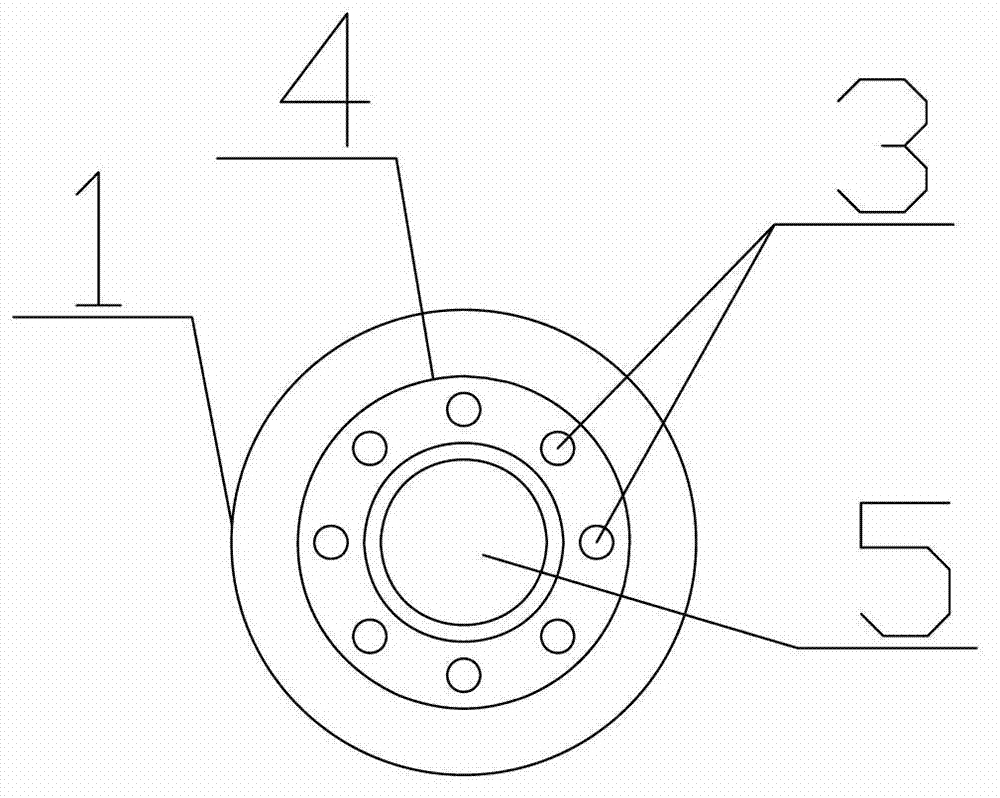

[0036] An SNCR denitrification automatic anti-blocking injection atomization spray gun device for smoke and dust environment, including a spray gun nozzle, a casing sleeve mounted on the spray gun nozzle, and a reducing agent inlet pipe; the spray gun nozzle communicates with the reducing agent inlet pipe, An annular dust-proof plate is arranged between the tube and the nozzle of the spray gun; the annular dust-proof plate is located at the nozzle end of the nozzle of the spray gun.

[0037] A plurality of air holes are arranged on the annular dustproof plate, and an air inlet pipe for introducing compressed air from an air source is arranged on the casing.

[0038] The plurality of air holes are arranged on the ring-shaped dustproof plate in a circumferentially equally divided manner. The stomata are circular holes.

[0039] The casing is provided with an inlet pipe for introducing gas from the gas source, and there is a gap between the annular dust-proof plate and the nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com