Method for calculating equivalent temperature field of large-size concrete based on cooling water monitoring

A large-volume concrete and equivalent temperature technology, applied to the direction of the thermometer that gives the difference, can solve the problems of lack of clear specifications and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

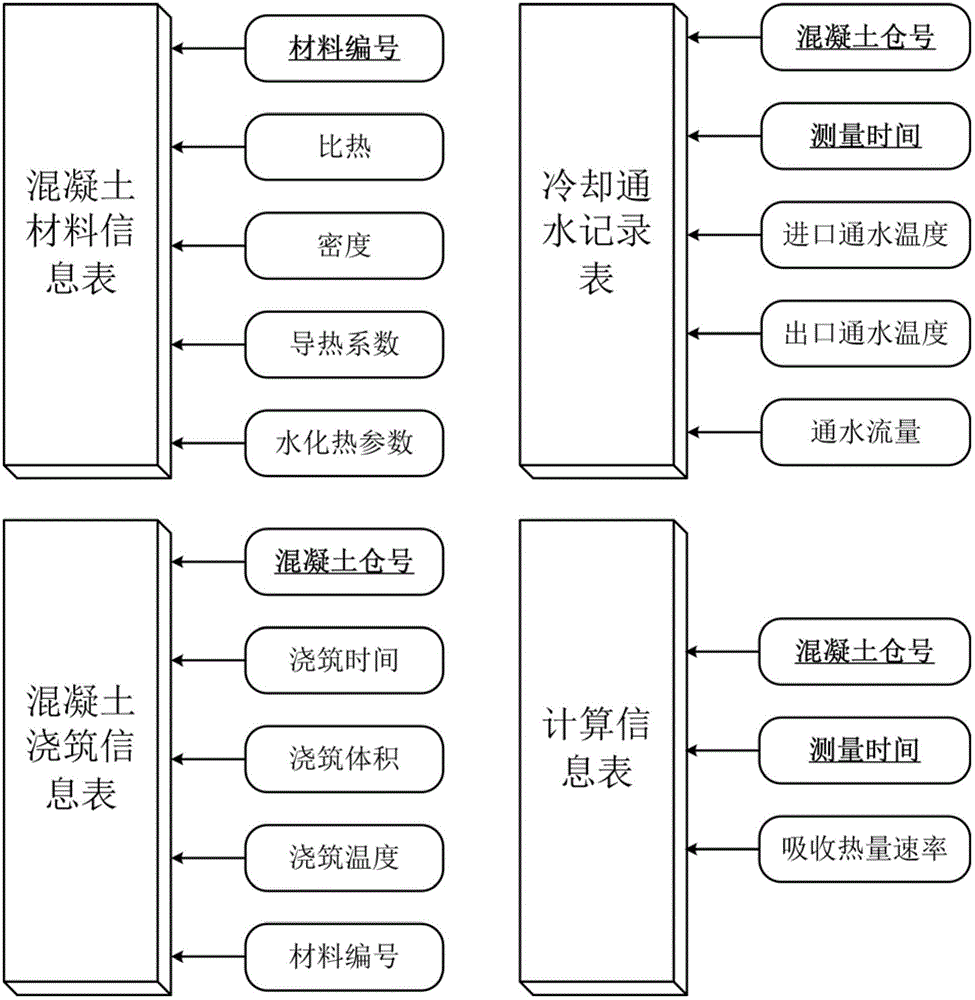

[0029] 1) First establish the database structure, which includes concrete material information table, concrete pouring information table, cooling water flow record table and calculation information table. The information organization form in each data table is as follows figure 1 As shown, the underline in the figure indicates the primary key in the table.

[0030] 2) Measure the material number, specific heat, density, thermal conductivity and heat of hydration parameters of at least one concrete used in the project through experiments, and enter them into the concrete material information table; among them, through relevant measuring instruments in the indoor test Specific heat, density, and thermal conductivity can be measured. The heat of hydration curve can be measured through the adiabatic temperature rise test. After a certain fitting, the relevant heat of hydration parameters can be obtained. In general engineering, the heat of hydration curve in the form of an index is...

Embodiment

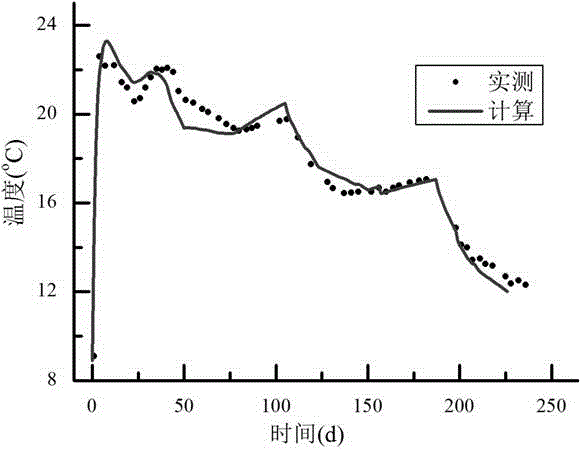

[0051] In the specific implementation, relevant tests were carried out for a concrete warehouse in a large concrete dam project during a certain construction period. The concrete pouring volume of the warehouse is 4358m 3 , Water faucets and water meters were installed at the inlet and outlet of the cooling water pipes in the warehouse. Since the warehouse was poured, monitoring personnel were arranged to manually collect the water temperature and flow rate of the inlet and outlet every 6 hours, and recorded it, and then returned to the office for input. in the database. The test period starts from the pouring date and ends 237 days after the pouring of the warehouse.

[0052] In the indoor test of the concrete for this project, the measured specific heat of the concrete is 0.985kJ / kg°C, and the density is 2663kg / m 3 , the thermal conductivity is 7.70kJ / mh°C. Since the mix ratio used contains a certain amount of fly ash, the heat of hydration curve measured by the test is bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com