Shift control device, shift control method, gearbox and construction machinery

A control device and control method technology, applied in mechanical equipment, transmission device control, components with teeth, etc., can solve problems such as power transmission performance degradation, achieve smooth power transfer, fast shift response, and reduce wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

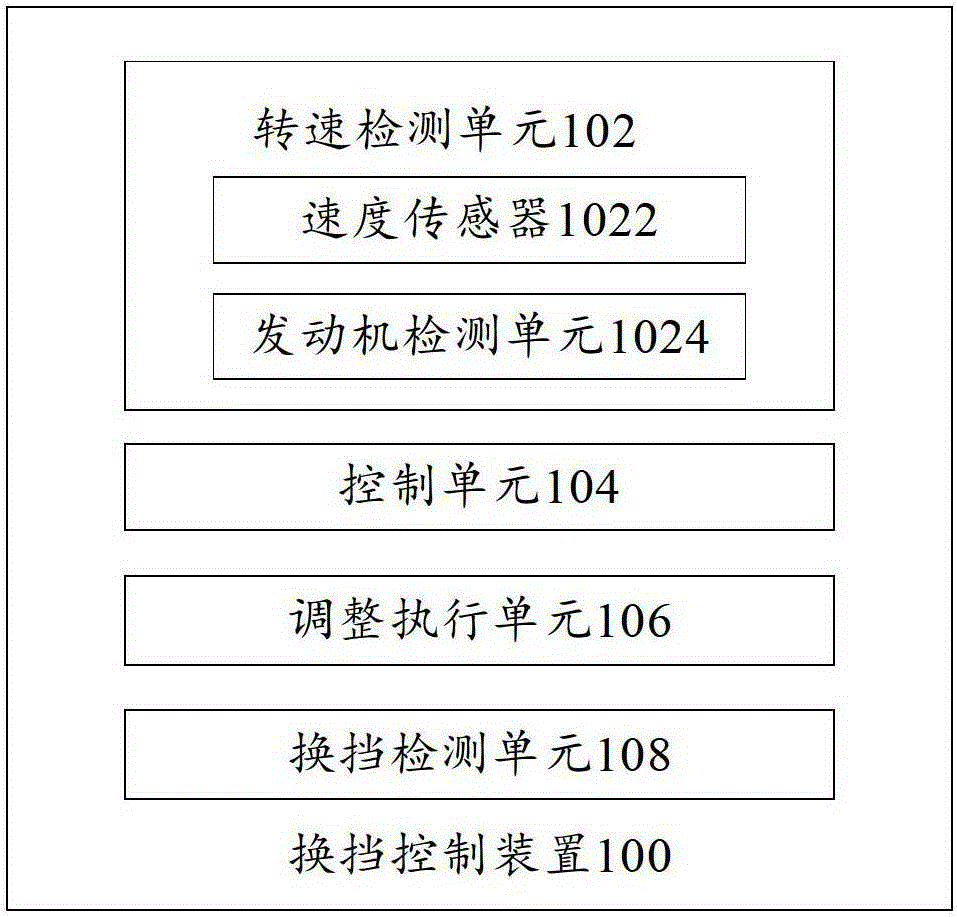

[0087] Such as Figure 8 As shown, the shift expert control device 800 provided in this embodiment includes:

[0088] The rotational speed detection unit 802 detects the rotational speeds of multiple shafts in the gearbox. The rotation speed detection unit 802 includes a rotation speed sensor 8022 arranged on each shaft of the gearbox, wherein the shaft A is connected to the engine, and the rotation speed of the shaft A can be obtained directly from the engine rotation speed (the sensor 8022 can be used to detect the rotation speed of the engine shaft, or the equivalent reading The engine detection unit 8024 of the interface reads the engine speed from the construction machinery system), and the other four axes obtain signals through the speed sensor 8022 to realize the monitoring of multi-axis speed, and the control unit 804 can obtain the speed of each shaft through analysis and calculation .

[0089] The control unit 804 is connected to the rotation speed detection unit 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com