Embedded column type prefabricated part connection node and manufacturing method thereof

A technology of prefabricated components and connecting nodes, which is applied in the direction of building structure, construction, and building material processing, etc., can solve problems affecting mechanical performance, affecting performance, complex structure, etc., to achieve improved performance, improved integrity, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

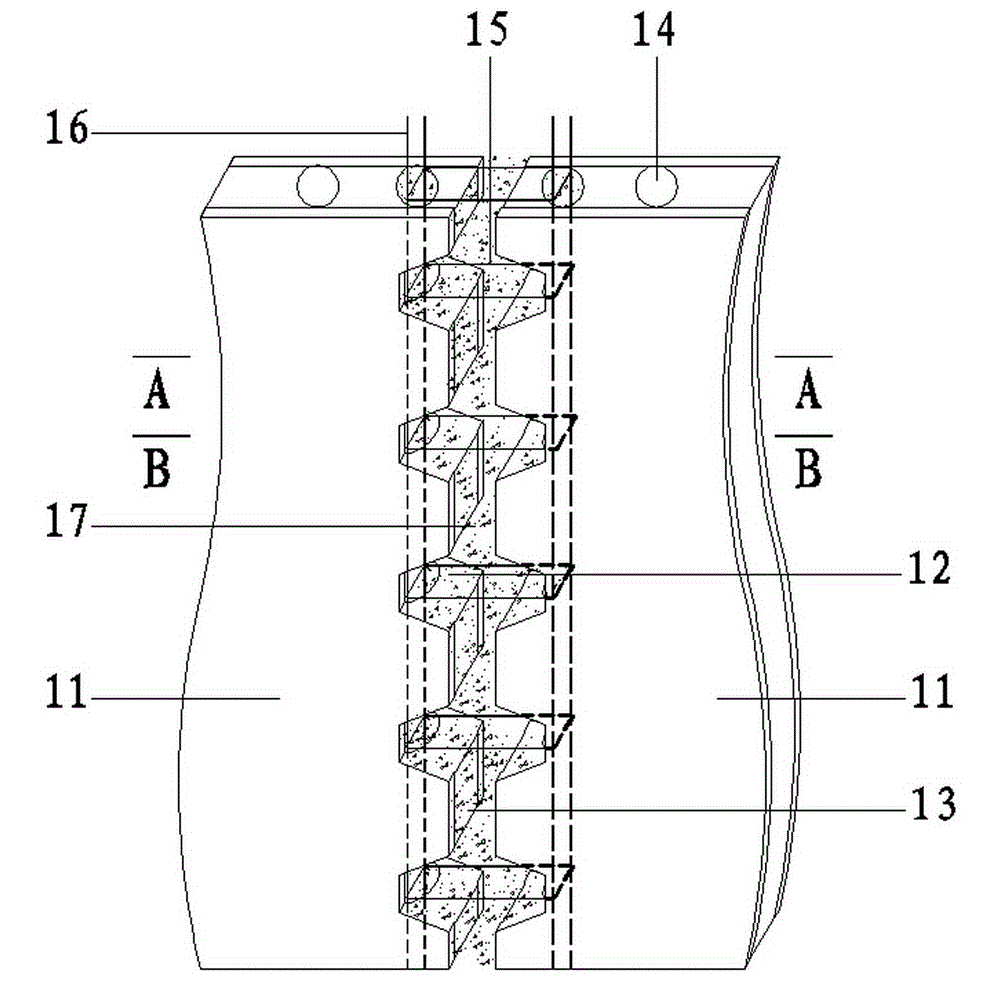

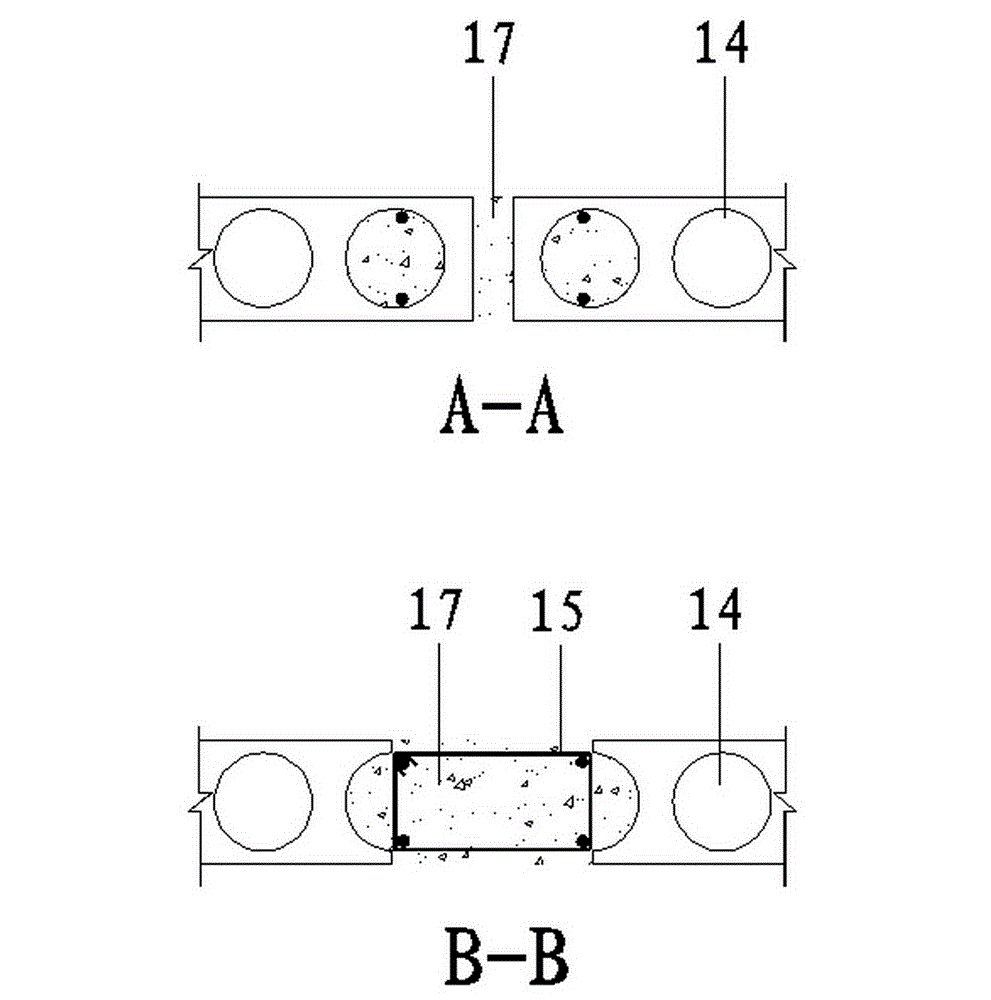

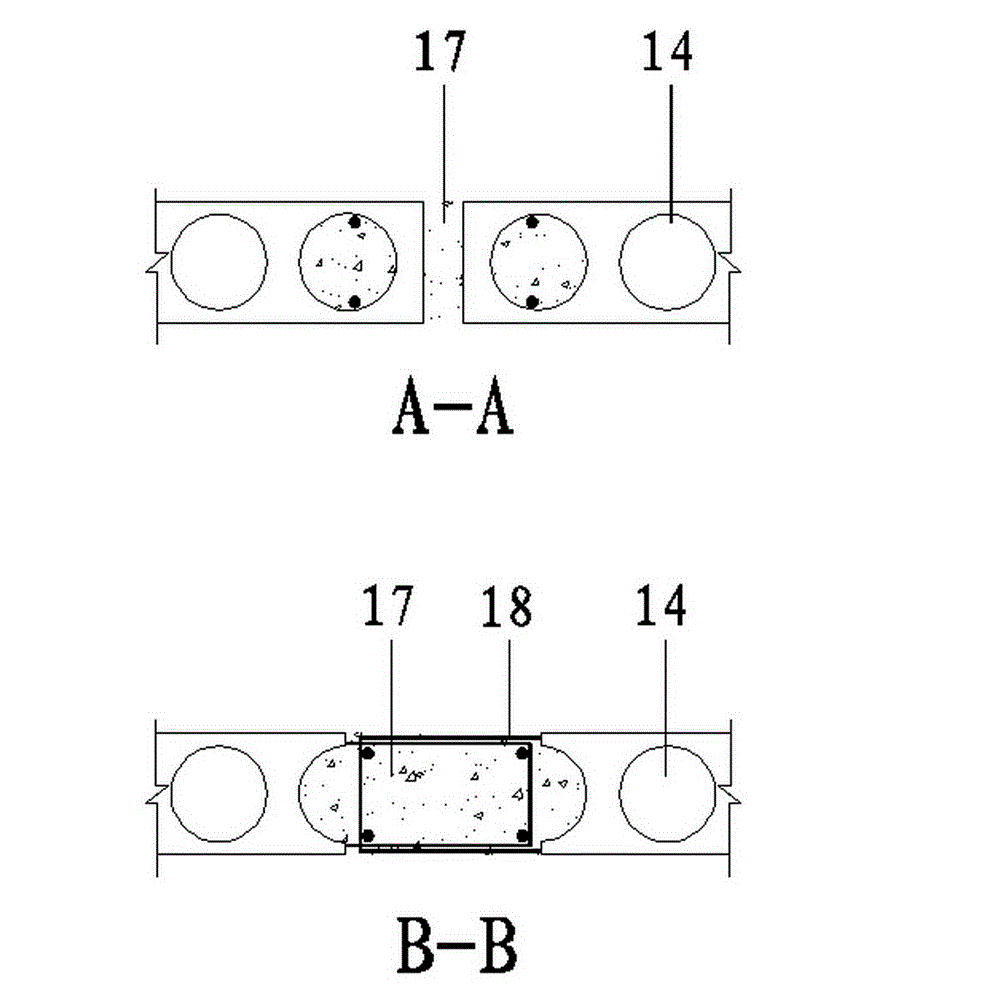

[0041] figure 1 , figure 2 It is a schematic diagram of an embodiment of the connection node of the concealed column type prefabricated component of the present invention. The stirrup is configured on site. The longitudinal edge of the prefabricated component 11 is arranged with transverse grooves 12, which are arranged alternately with the protrusions 13; The holes on the edge intersect with the transverse grooves 12; the transverse grooves 12 on both sides of the node are arranged oppositely to form a space, in which the stirrups 15 configured on site are arranged; the longitudinal bars 16 are arranged in the longitudinal holes, pass through the stirrups 15, and Stirrups 15 form the steel skeleton (when the stress is small or the length of the stirrups 15 extending into the groove of the prefabricated component meets the anchoring requirements, the longitudinal reinforcement 16 may not be provided); the post-cast concrete fills the longitudinal holes on the outside of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com