Manual mechanical oil-pouring device

A manual machine and oil pouring technology, used in packaging, emptying containers, bottle filling, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of reducing labor intensity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

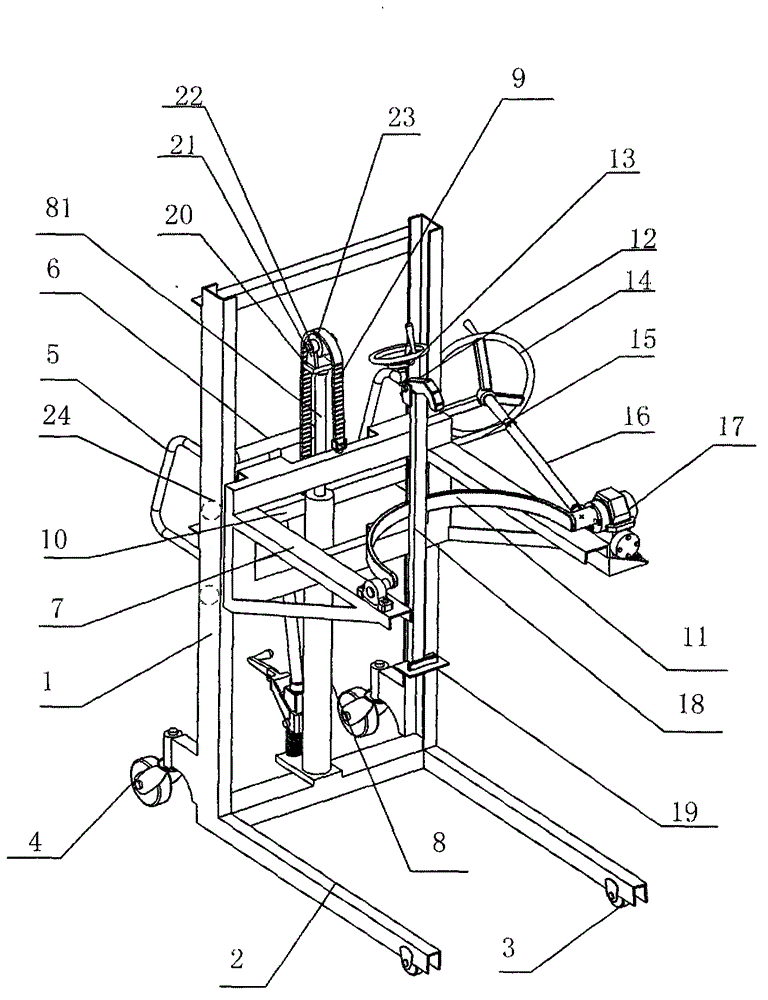

[0011] see figure 1 , the present invention relates to a manual mechanical oil pouring device, comprising a door frame 1, a base 2, a front wheel 3, a steering wheel 4 and a handrail 5, a base 2 is connected to the bottom end of the door frame 1, and the front end of the base 2 Front wheels 3 and steering wheels 4 are respectively installed at the bottom and rear end of the door frame 1, and handrails 5 are installed on the top of the door frame 1. It is characterized in that: a lifting frame 7 is installed on the door frame 1, and the lifting frame 7 corresponds to the base 1 and is located on the same side of the door frame 1. The lifting frame 7 moves up and down on the door frame 1 through the drive of the lifting mechanism, and also includes a half round hoop 11, one end of which is rotated Installed on the lifting frame 7, the other end is connected with a turning mechanism, and a clamping mechanism is installed on the semicircular hoop 11.

[0012] The lifting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com