Automatic folding mechanism for valve bag tongue port

A technology of folding mechanism and valve pockets, which is applied in container manufacturing machinery, paper/cardboard containers, and box production operations, etc. It can solve the problems of large production batches, low work efficiency, and a large number of workers for valve pockets, so as to save labor costs and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

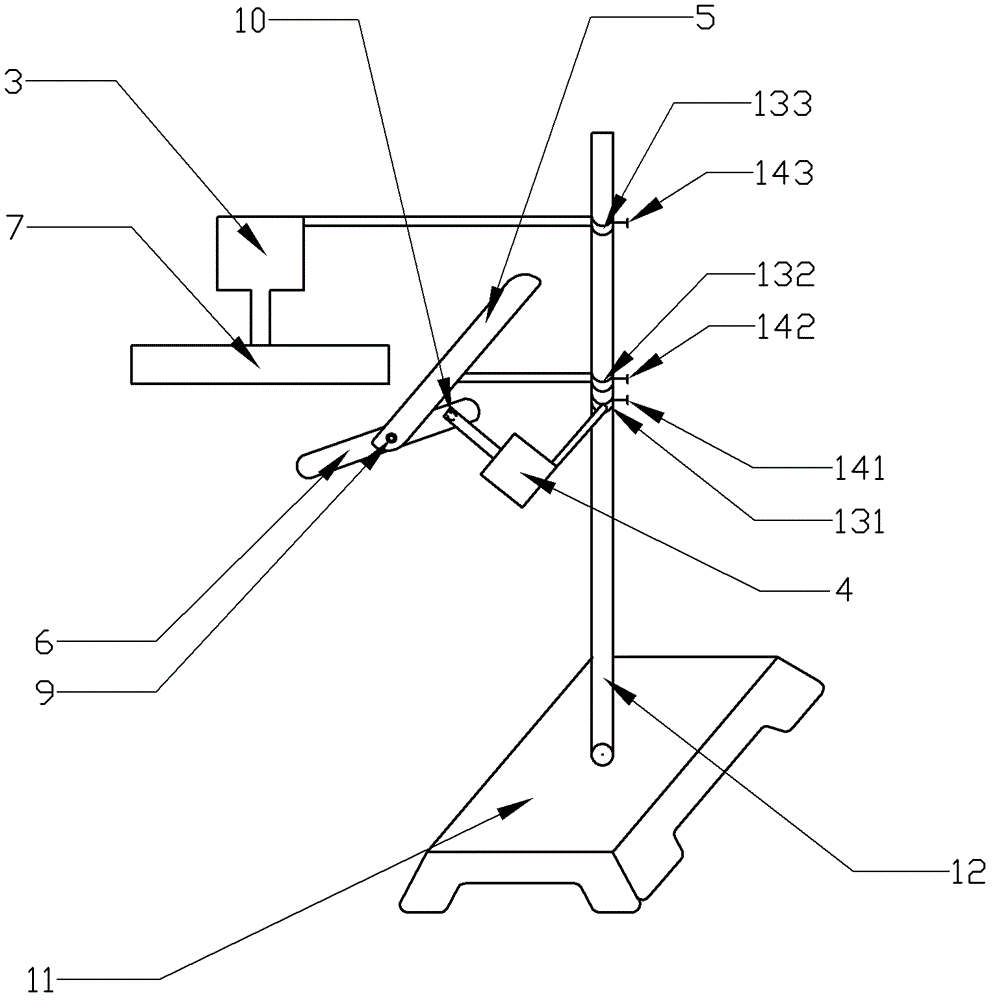

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

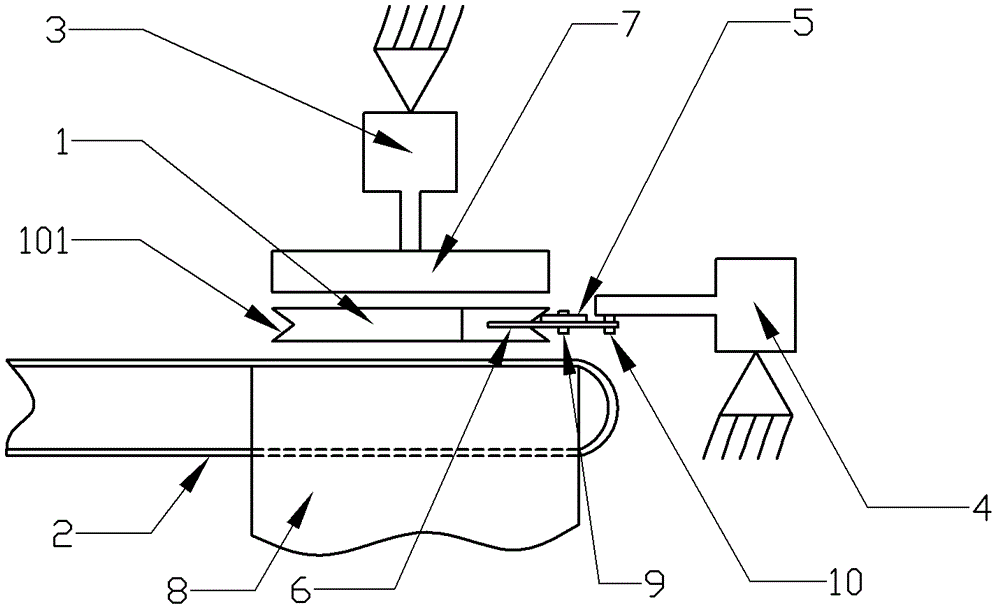

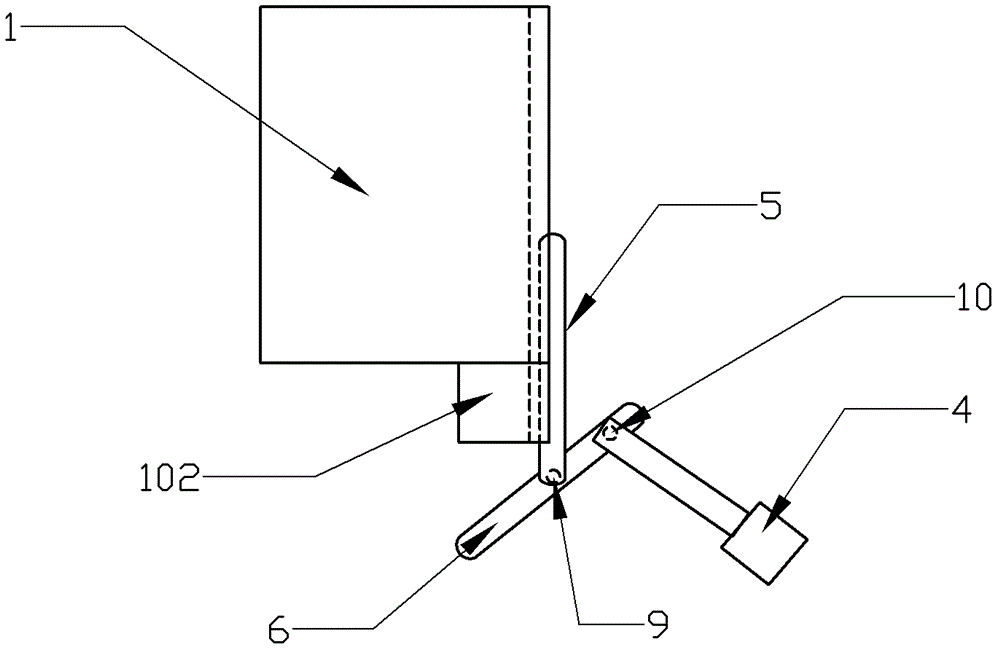

[0018] like figure 1 , figure 2 As shown, a valve bag tongue automatic folding mechanism, its structure includes:

[0019] A fixed piece 5 is located in the M-shaped pressure edge 101 on the side of the valve pocket 1 close to the tongue 102 and is arranged longitudinally along one side of the valve pocket. The middle part of a movable piece 6 is connected to the fixed piece 5 through the first hinge shaft 9 . Wherein, the tongue opening 102 of the valve pocket 1 and the M-shaped bead 101 on one side of the valve pocket are formed in the previous process. It is laid on the frame 8 working surface of this machine.

[0020] The relationship between the fixed piece 5 and the movable piece 6 is preferably that the fixed piece 5 is on the top and the movable piece 6 is below, which is more conducive to the forward movement of the valve pocket 1, and the deflection angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com