Method for applying leather to vehicle interior parts

A technology of leather and components, which is applied in the direction of bonding method, steering control installed on the car, leather, etc., can solve the problems of unsuitable protection of leather covering, processing difficulties, etc., and achieve leather saving, cost advantage, and position optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

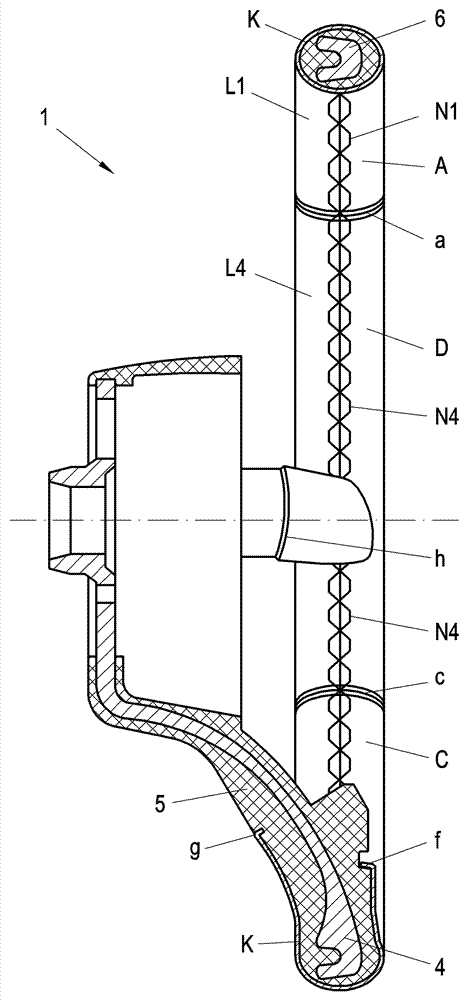

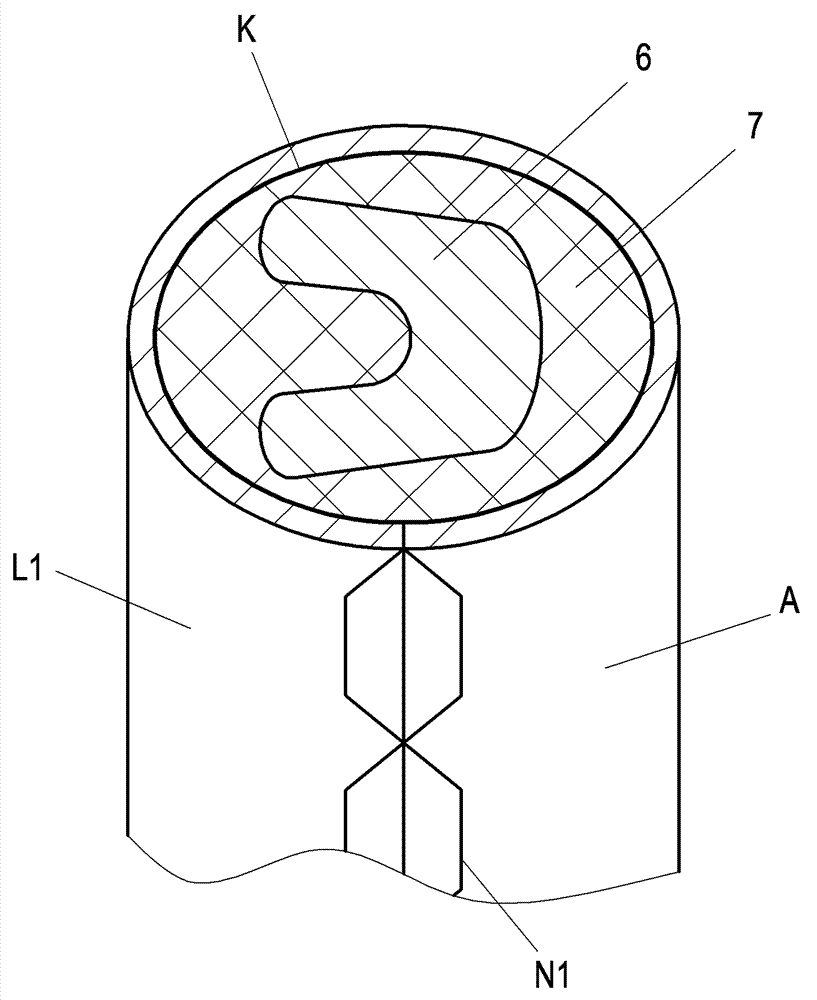

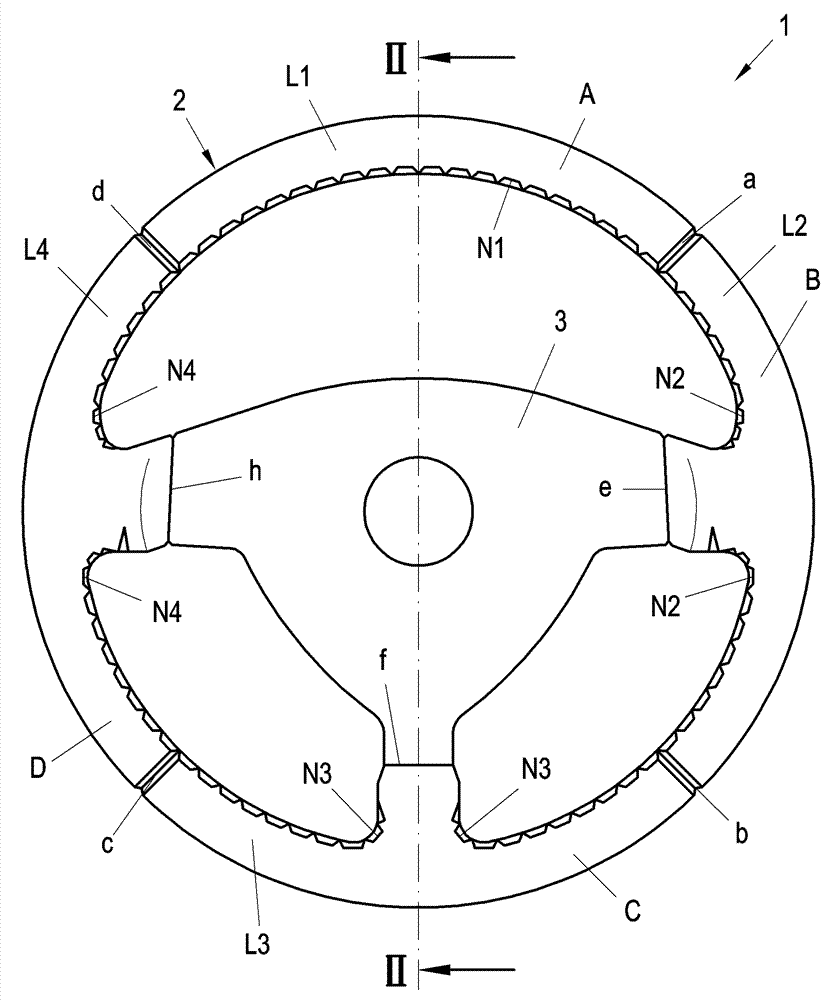

[0025] figure 1 A leather steering wheel 1 of a car is shown. The leather steering wheel 1 has a handle portion 2 and a spoke portion 3 . The handle part 2 is divided into four sections A, B, C and D, each of which are offset relative to each other by slots a, b, c and d running around the handle part. In order to surround the steering wheel with leather or to leather the steering wheel during the manufacture of the steering wheel, each section of the steering wheel is produced with a so-called leather coating. The leather covering consists of one or more stitched leather pieces, which are cut or punched and sewn in such a way that the leather covering fits precisely to the corresponding section of the steering wheel. The corresponding sections of leather covering are glued flat to the steering wheel and are fastened to the steering wheel by grooves and seams.

[0026] exist Figures 1 to 3 In the leather steering wheel 1 shown in , the first leather coating L1 covers the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com