Gate driver on array unit, gate driver on array circuit and display device

A technology of array substrate rows and driving units, applied in the field of organic light-emitting display, can solve the problems of large voltage drop, short driving time, and high OLED operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Compared with AMLCD (Active Matrix Liquid Crystal Display), AMOLED (Active Matrix Organic Light-Emitting Diode) needs to be driven by an increased current, so it is mostly realized by low-temperature polysilicon circuits with greater mobility. In order to compensate the threshold voltage drift problem of polysilicon TFT (thin film transistor), the pixel circuit of AMOLED often needs a corresponding compensation structure, so the pixel circuit structure of AMOLED is more complicated, and correspondingly needs to occupy a larger layout (circuit layout) area.

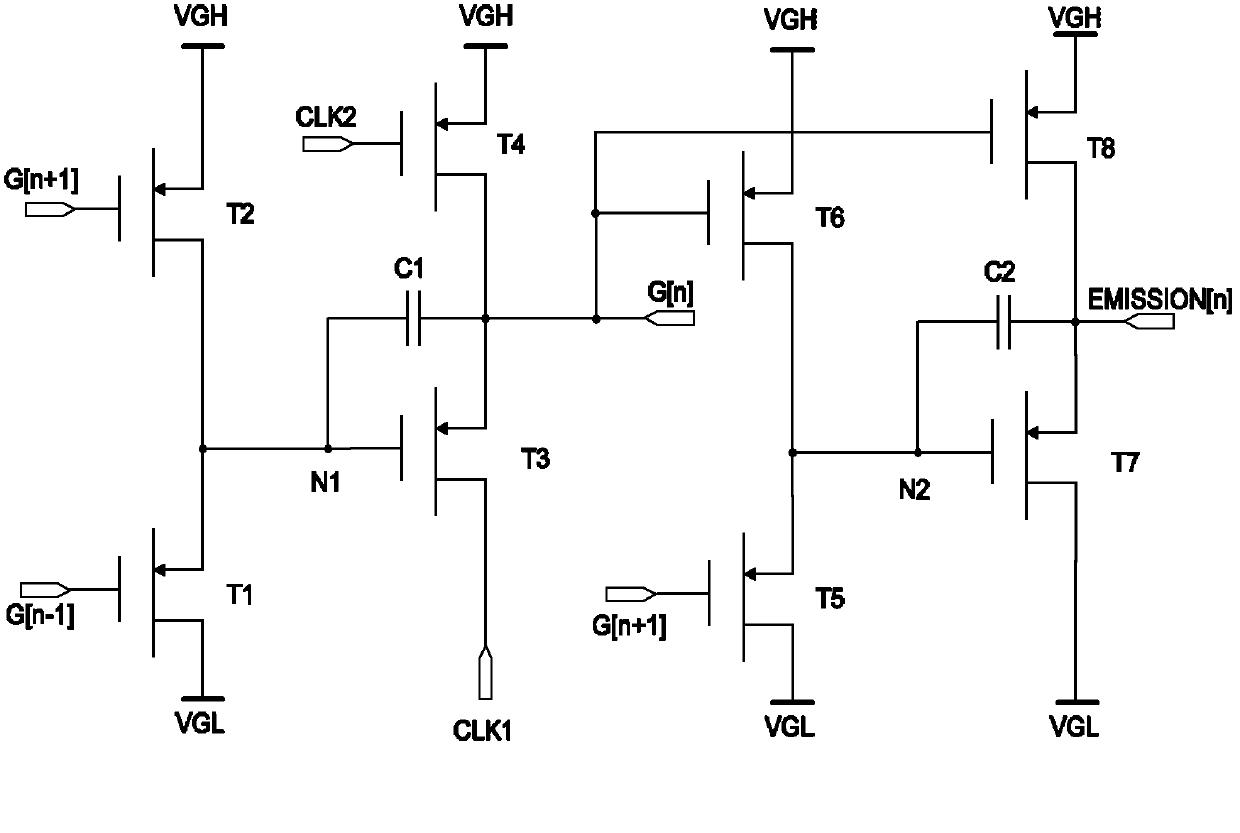

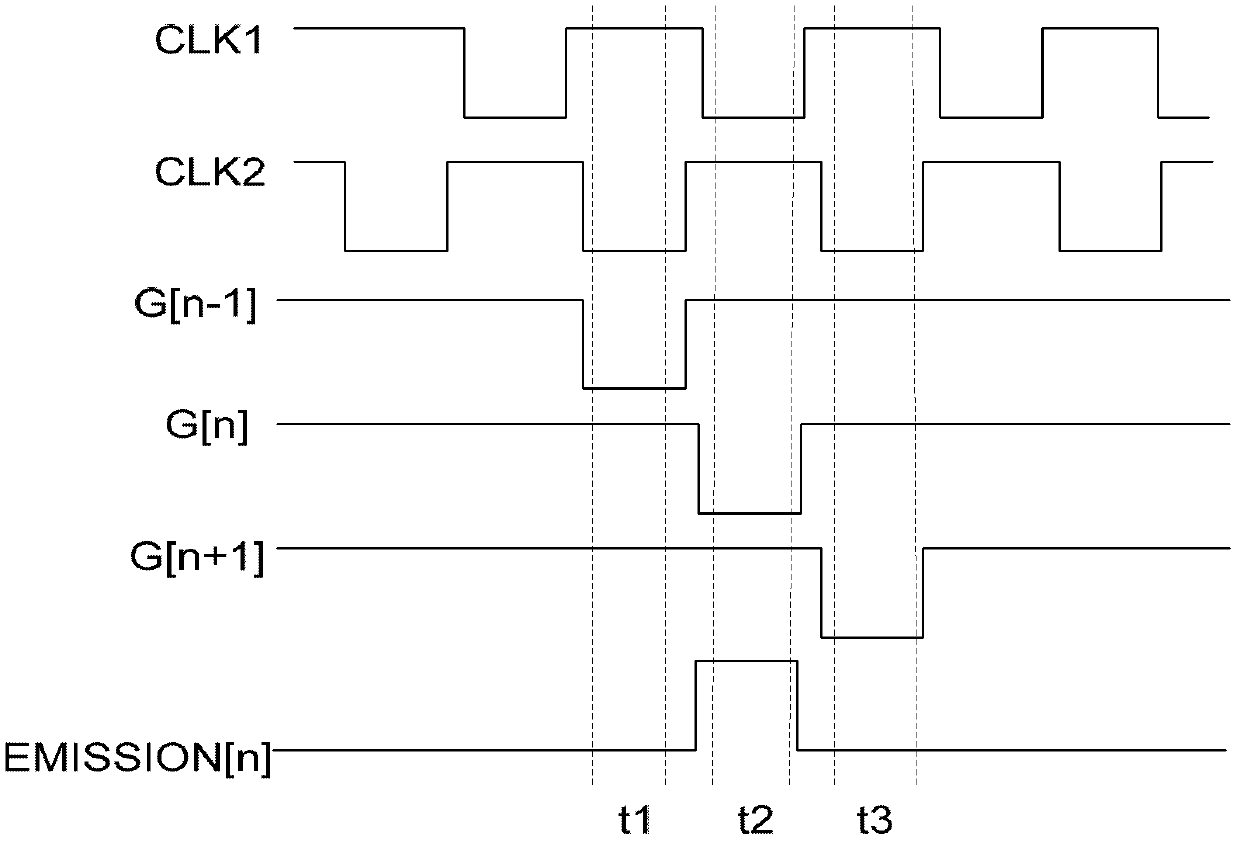

[0052]The invention provides an array substrate row drive circuit for an active matrix organic light-emitting display with simple structure and stable performance. array substrate row drive unit. Each array substrate row driving unit includes 8 thin film transistors and 2 capacitors. The row driving unit of the array substrate is divided into two stages, the first stage is used for generating conventional gate lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com