Ultrasonic phased array detection system for transitional circular arc inside cavity

An ultrasonic phased array and transition arc technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. Detection sensitivity and other issues, to achieve the effect of high-sensitivity detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

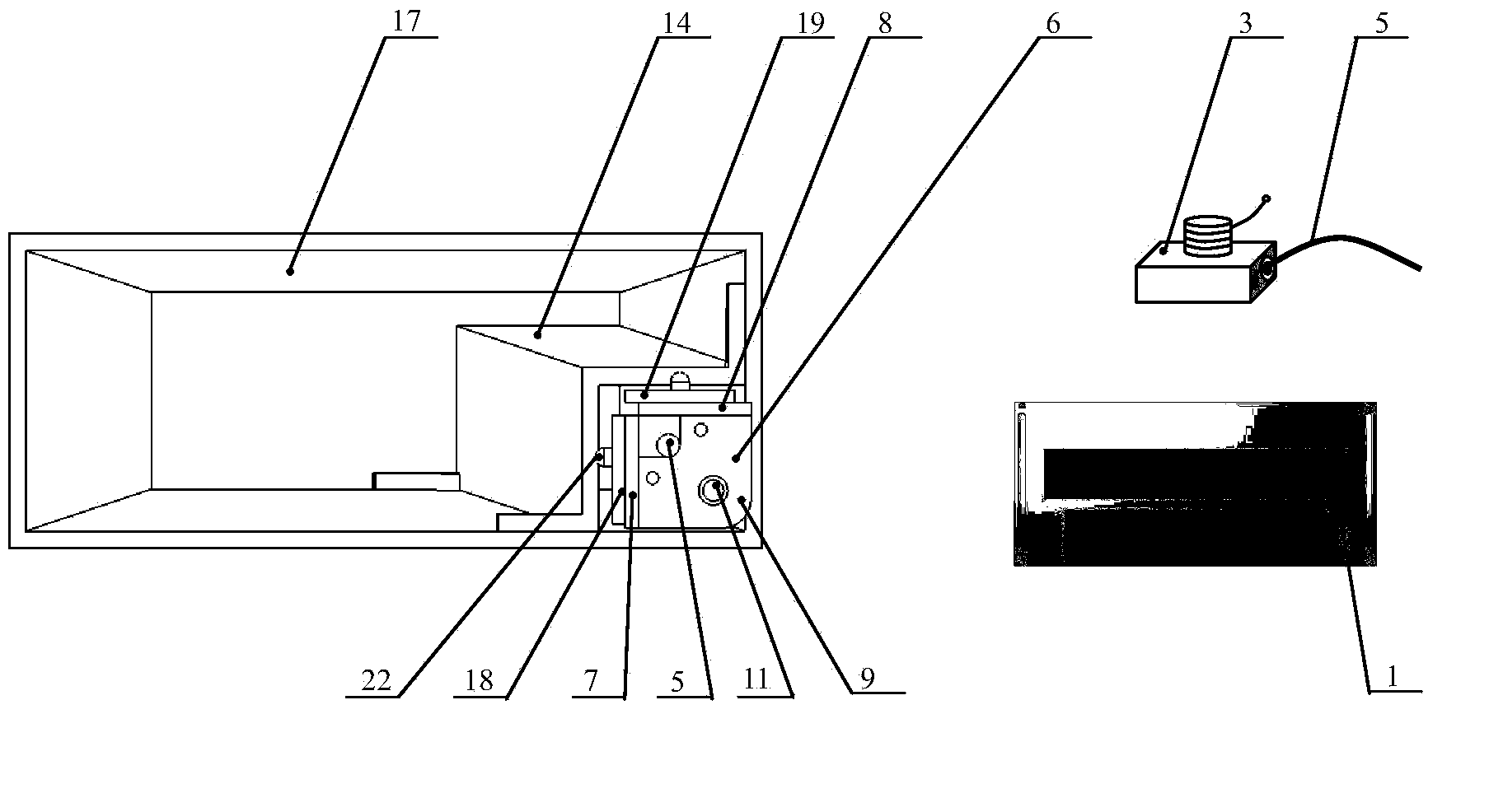

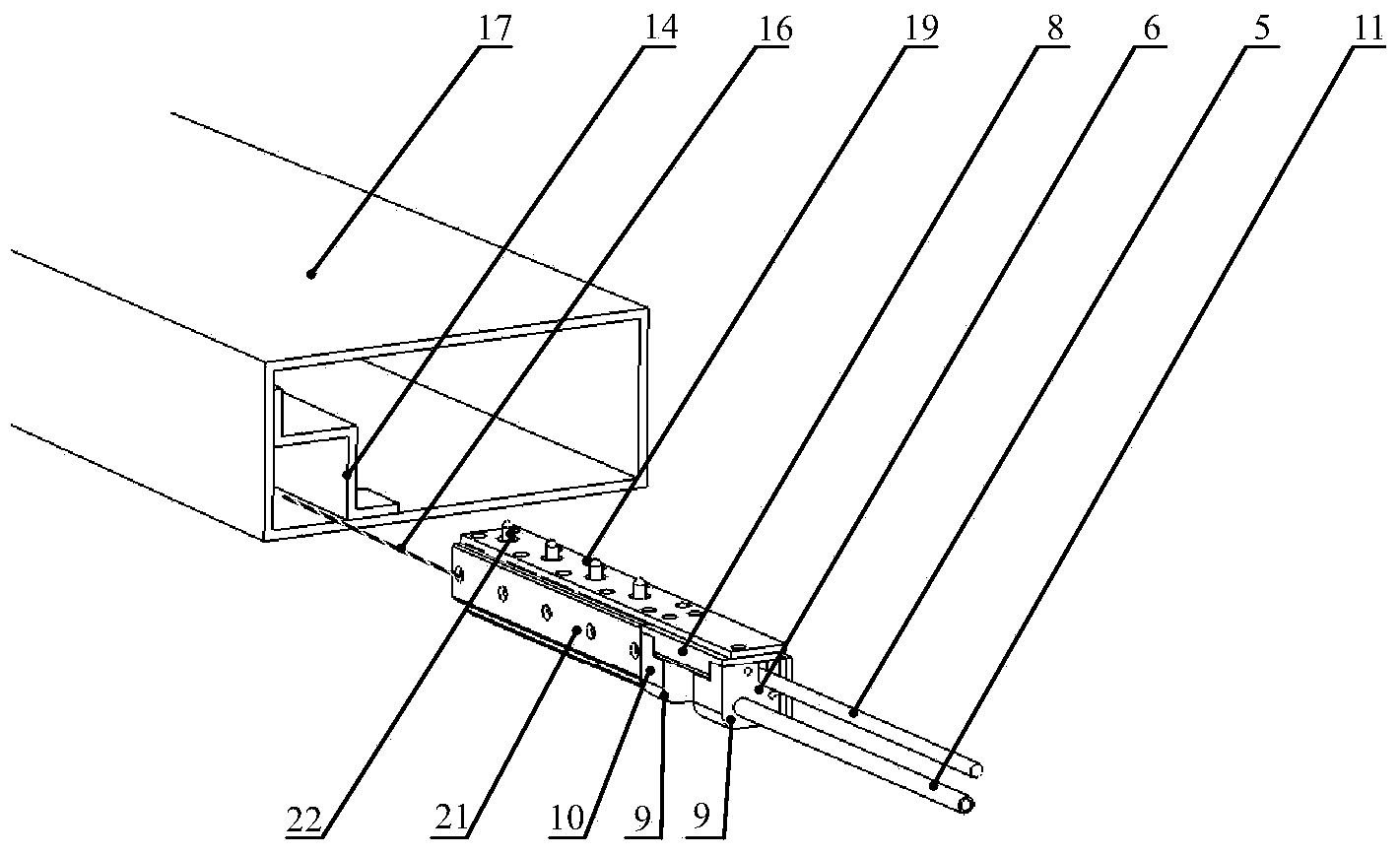

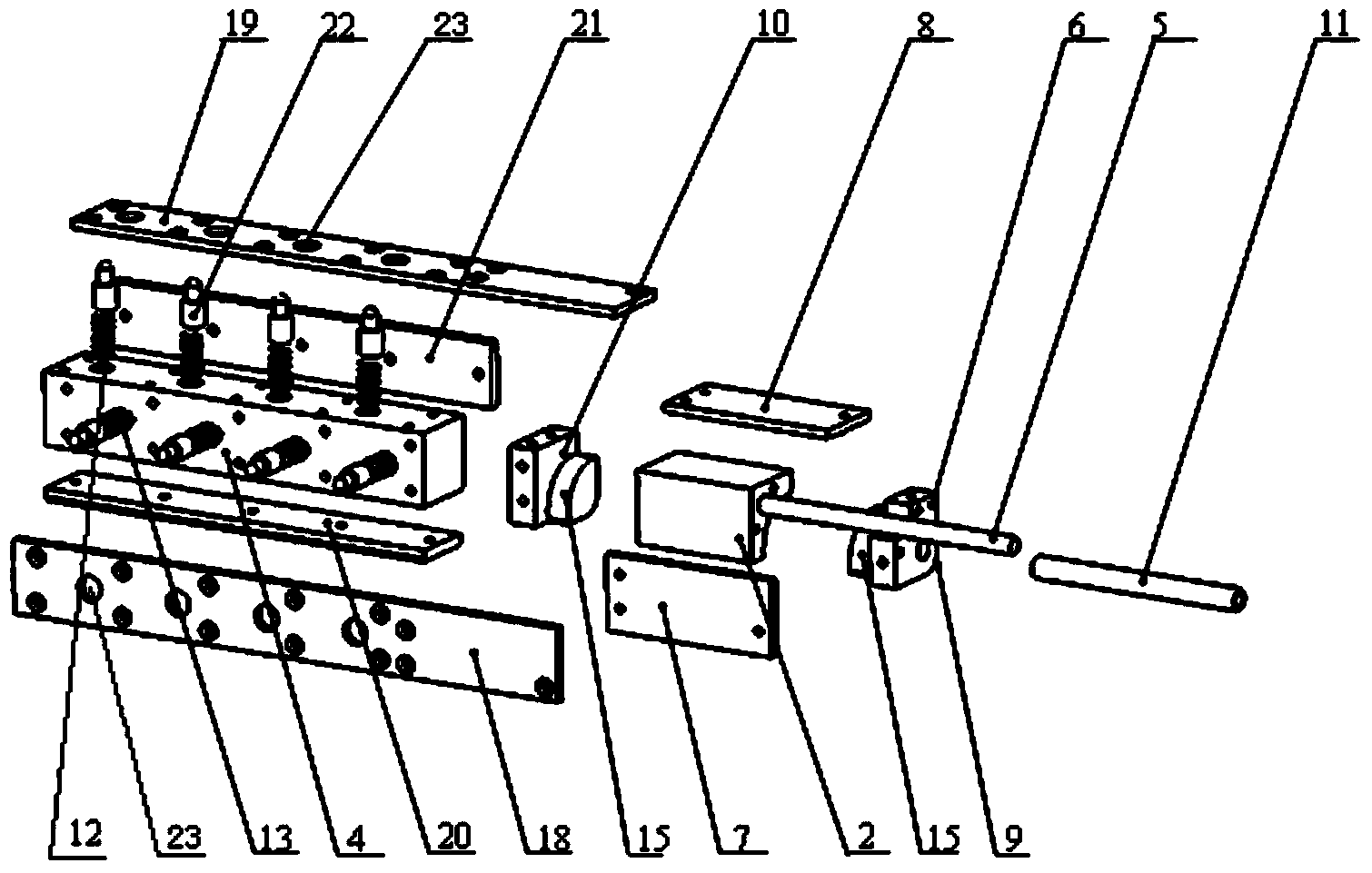

[0023] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0024] Referring to the accompanying drawings, the technical scheme of the present invention is used to detect the arc position of 75°-120° inside the cavity structure of a composite material of a certain material system.

[0025] Figure 4 The inner arc angle of the cavity structure shown is 75°, the maximum width of the internal section of the cavity is 80mm, the maximum height is 60mm, the wall thickness is 5mm, and the chamfer radius is 5mm; Figure 5 The inner arc angle of the cavity structure shown is 90°, the maximum width of the internal section of the cavity is 75mm, the maximum height is 65mm, the wall thickness is 5mm, and the chamfer radius is 5mm; Figure 6 The inner arc angle of the cavity structure shown is 120°, the maximum width of the internal section of the cavity is 100 mm, the maximum height is 70 mm, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com