Electric control type thermosistor

A thermostat, electronically controlled technology, applied in the direction of machine/engine, coolant flow control, engine components, etc., can solve the problems of wire breakage, power failure, large water resistance, low sensitivity, etc., to avoid wire breakage The effect of stable power failure, fast heating conduction, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

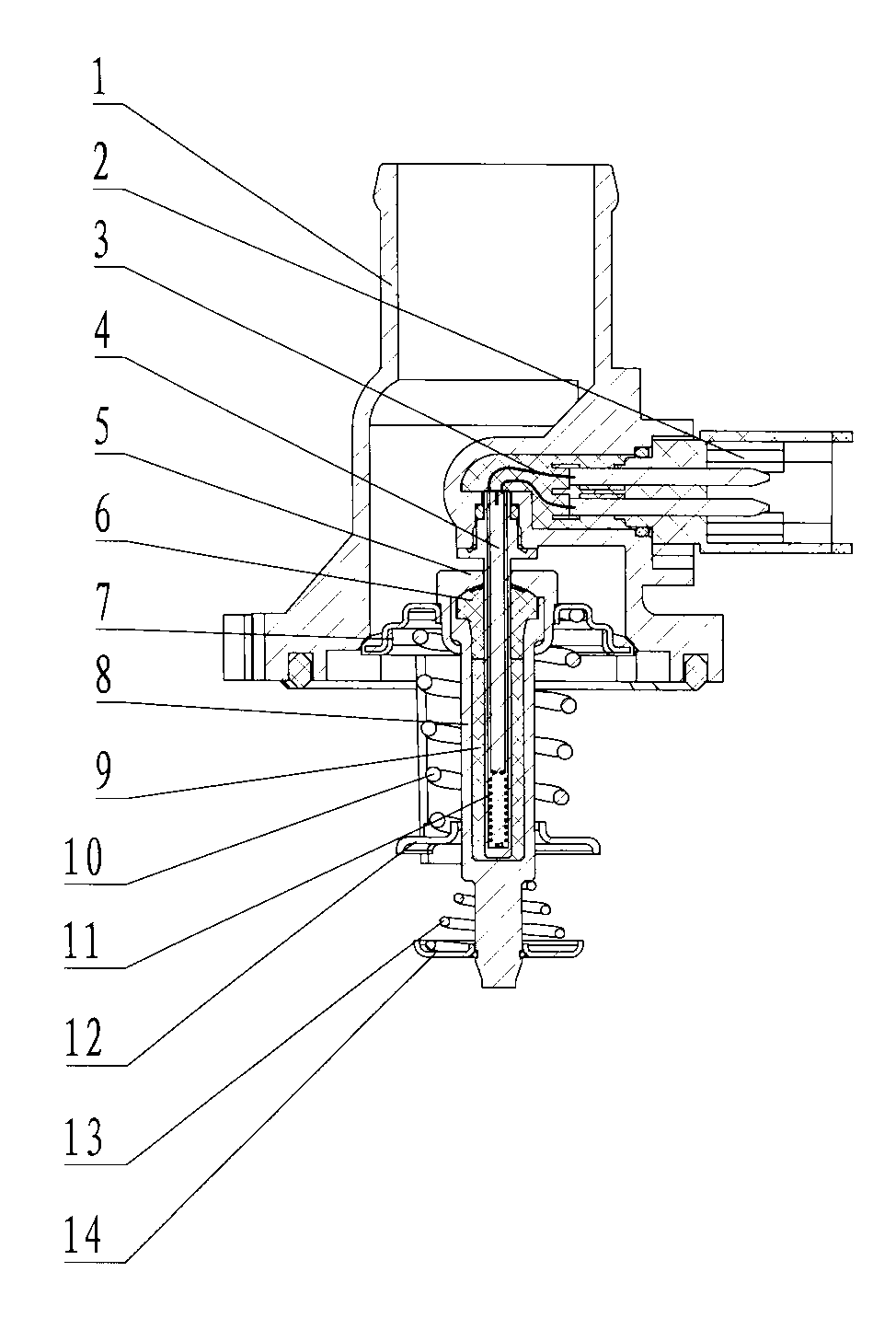

[0009] refer to figure 1 , there is a chamber 1 with two ports, a plug 2 for connecting wire 3 is arranged on one side of the chamber 1, a heated pushing mechanism with a valve 7 and a push rod 4 is installed on the chamber 1, and the heated pushing mechanism has A body 8 with a blind hole, a push rod 4 is inserted in the inner hole of the body 8, the other end of the push rod 4 protrudes outside the body 8, and a sealing ring 6 that is sealed with the opening end of the body 8 is sleeved on the push rod 4, The opening end of the body 8 is riveted to buckle the gland 5 of the sealing ring 6, and the closed space between the inner hole of the body 8 sealed by the sealing ring 6 and the push rod 4 is filled with paraffin 9, and the gland 5 is riveted to the port of the cavity 8 Corresponding to the sealed valve 7, the body 8 is covered with a spring 10 with one end pressed on the valve 7. The other end of the spring 10 is supported on the bracket 12 that guides the body 8 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com