Modular cutting tooth with controllable drilling specific pressure

A technology of cutting teeth and specific pressure, used in drill bits, drilling equipment, earth-moving drilling, etc., to achieve the effect of improving the effective utilization rate, increasing the ROP, and increasing the life of the drill bit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

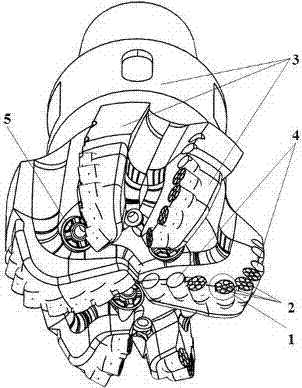

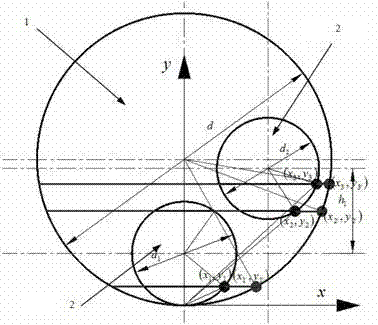

[0062] Embodiment 1: Modular unit scheme one

[0063] Such as image 3 As shown, the number of module units is 2, and the cross-sectional shape of modules and module units is circular. The diameter of the module is d, the type of the module unit is 2, and the quantity is 2, which are respectively unit 1 and unit 2, and the diameters are d 1 、d 2 , where d 1 Tangent to d, the distance between the centers of the two units in the y direction is h 1 ,and

Embodiment 2

[0064] Embodiment 2: Modular unit scheme two

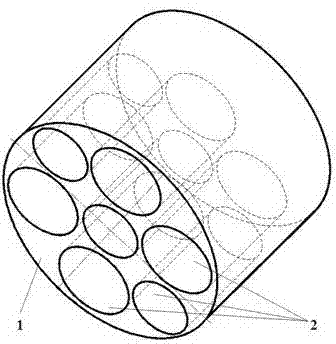

[0065] Such as Figure 5 As shown, the cross-sectional shape of the modules and module units is circular, all units are inside the modules, and there are intervals between the units. The diameter of the module is d, the number of module units is 4, the type is 2, and the diameter is d 1 、d 2 , including module (1), module unit (2).

Embodiment 3

[0066] Embodiment 3: Modular unit scheme three

[0067] Such as Figure 7 As shown, the module cross-section is runway-shaped, and the cross-sectional shapes of the module units are of different types such as circle, rhombus, triangle, rectangle, etc., and are regularly distributed, including module (1) and module unit (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com