Viaduct drop-off deformation seam structure and construction method of viaduct drop-off deformation seam structure

A technology of deformation joints and viaducts, which is applied to the structure of deformation joints between viaducts and drop-off platforms and its construction field, can solve problems such as unsatisfactory, and achieve the effects of ensuring waterproof and moisture-proof, reasonable structure settings, and improving road surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

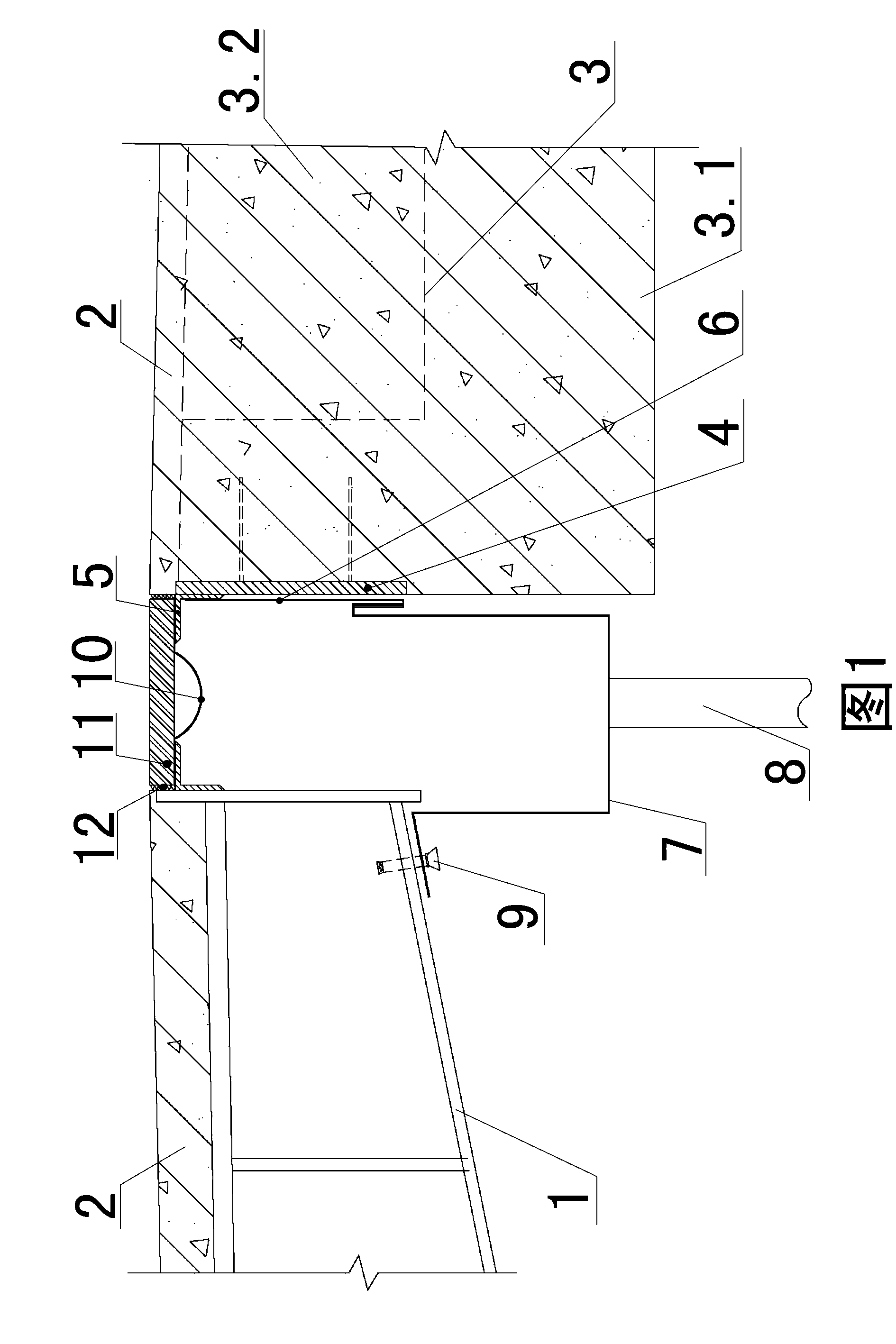

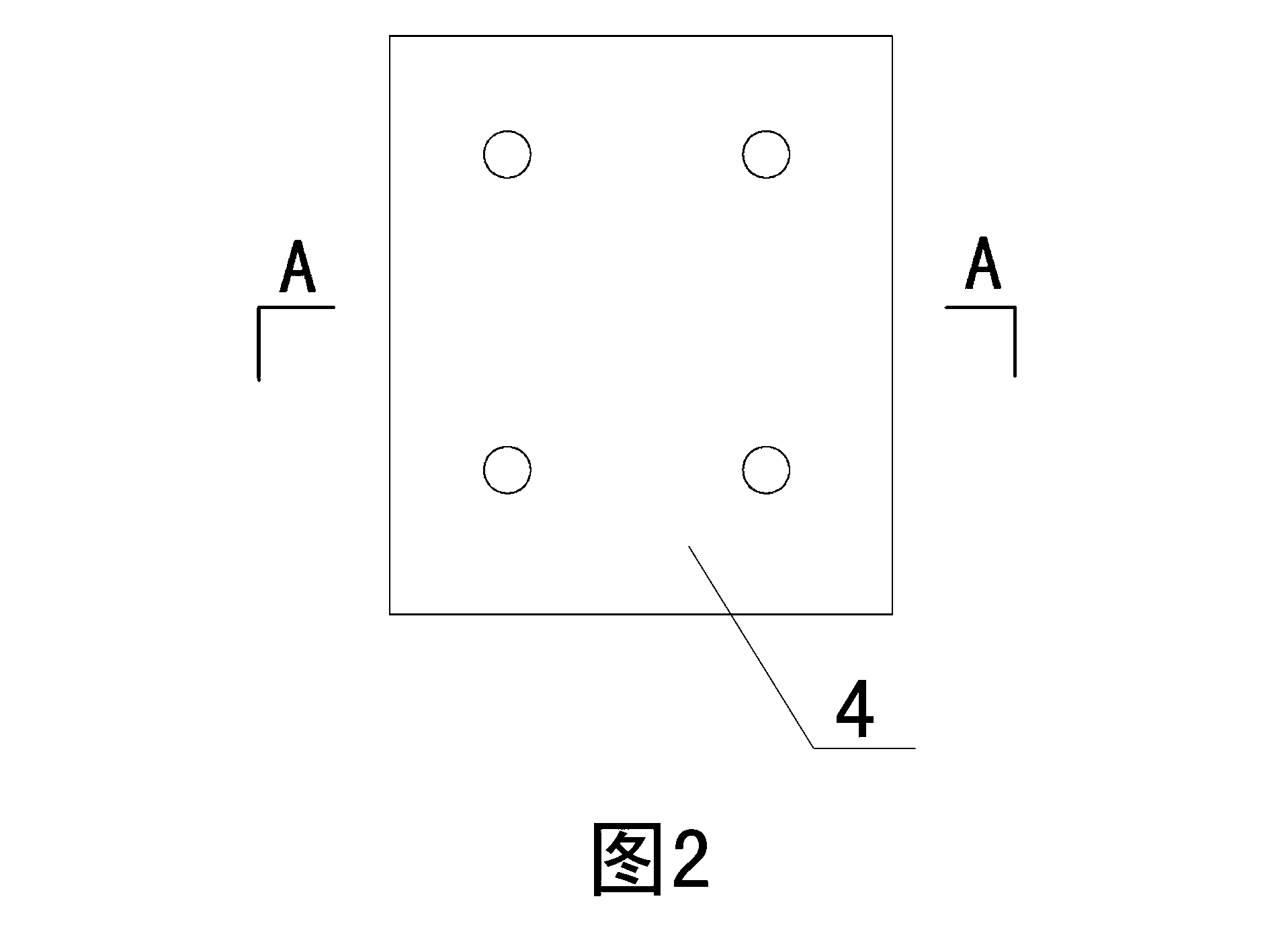

[0033] Examples see Figure 1-3 As shown, a viaduct drop-off deformation joint structure is arranged between the box-shaped steel structure 1 and the concrete structure 3, and the side of the concrete structure 3 corresponding to the box-shaped steel structure is fixed with a pre-embedded steel part 4. The upper part of the buried steel part 4 and the upper part of the box-shaped steel structure 1 are correspondingly welded with a steel support 5 facing the deformation joint, and a waterproof coiled material 10 is laid on the steel support 5 along the length direction of the deformation joint. The two sides of the waterproof coiled material 10 are placed on the steel support 5, and the middle part is suspended in the deformation joint. A steel pressing plate 11 is placed on the upper surface of the waterproof coiled material 10, and the steel pressing plate 11 covers the deformation joint. The steel pressing plate 11 Asphalt paste 12 is respectively embedded at the junction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com