Adaptive polishing robot mechanism

A robotic and self-adaptive technology, applied in grinding machines, manipulators, grinding/polishing equipment, etc., can solve the problems of low grinding and polishing efficiency, and achieve the effect of easy contact and separation, easy control, good flexibility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

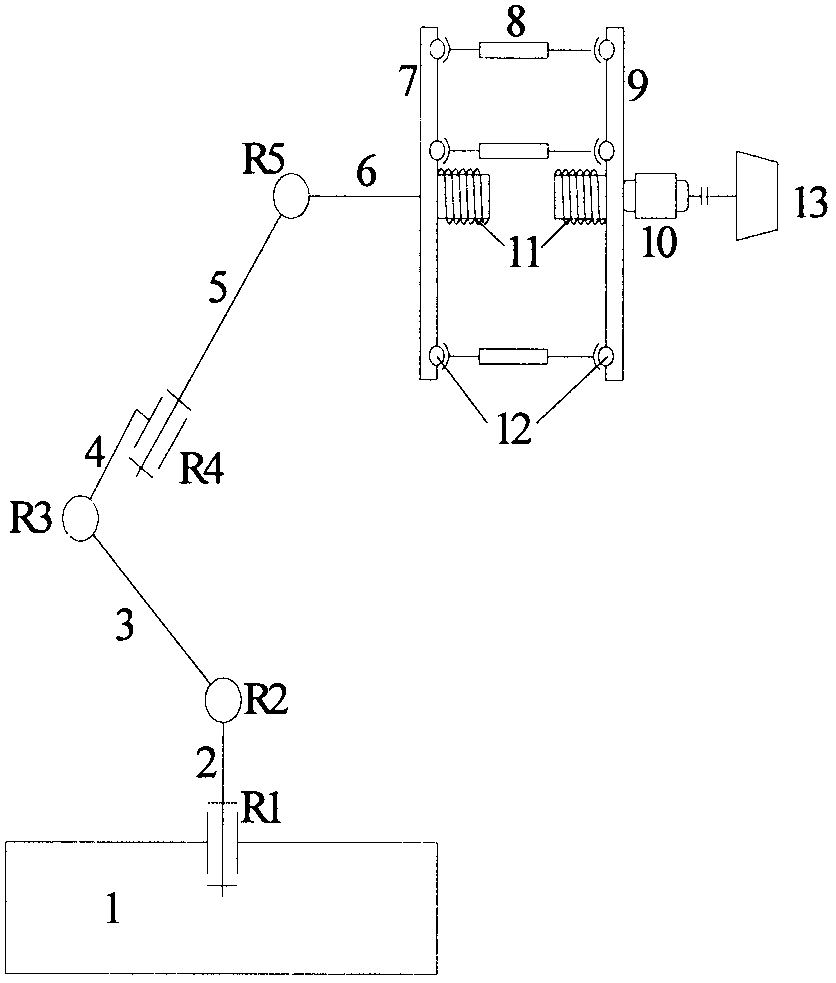

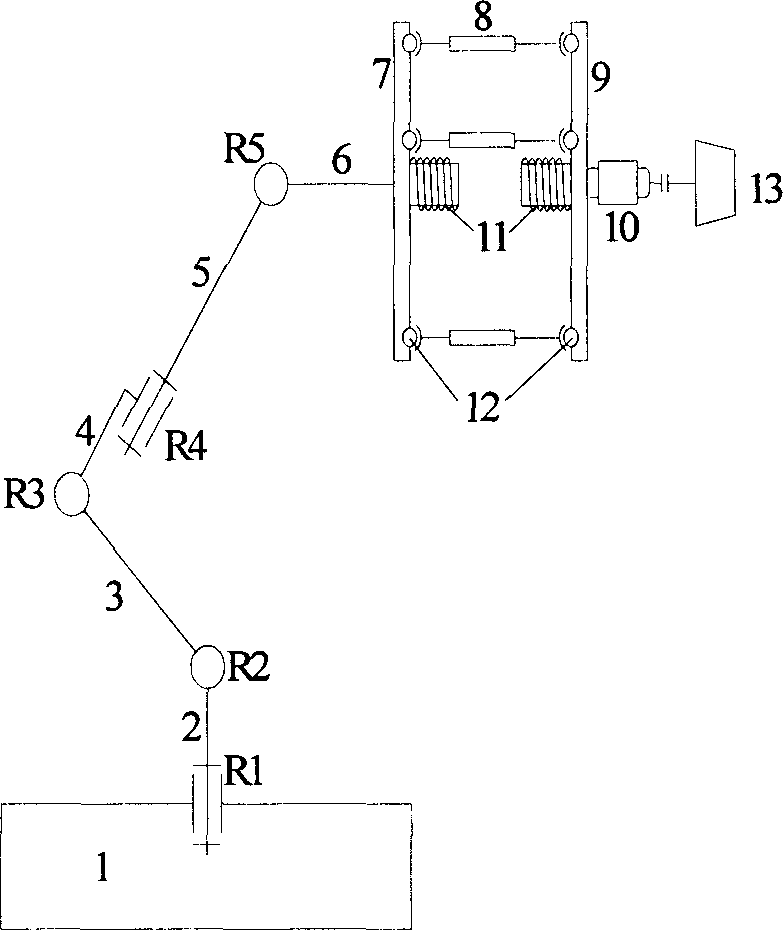

[0007] The technology of the present invention will be further described below by means of the accompanying drawings.

[0008] The technical solution of an embodiment of the present invention is: an adaptive grinding robot mechanism, including a series manipulator and a retractable parallel grinding head. 5. The end member 6 is composed of the first rotating pair R1, the second rotating pair R2, the third rotating pair R3, the fourth rotating pair R4, and the fifth rotating pair R5 in series. The scalable parallel grinding head includes a static platform 7, a dynamic platform 9, a grinding Head 13, three gas springs 8, the static platform 7 is fixed on the end member 6, an electromagnet 11 with opposite magnetic poles is respectively fixed at the center of the static platform 7 and the moving platform 9, and the two ends of the three gas springs 8 are respectively connected to the static by the ball pair 12. The platform 7 and the moving platform 9 are connected and evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com